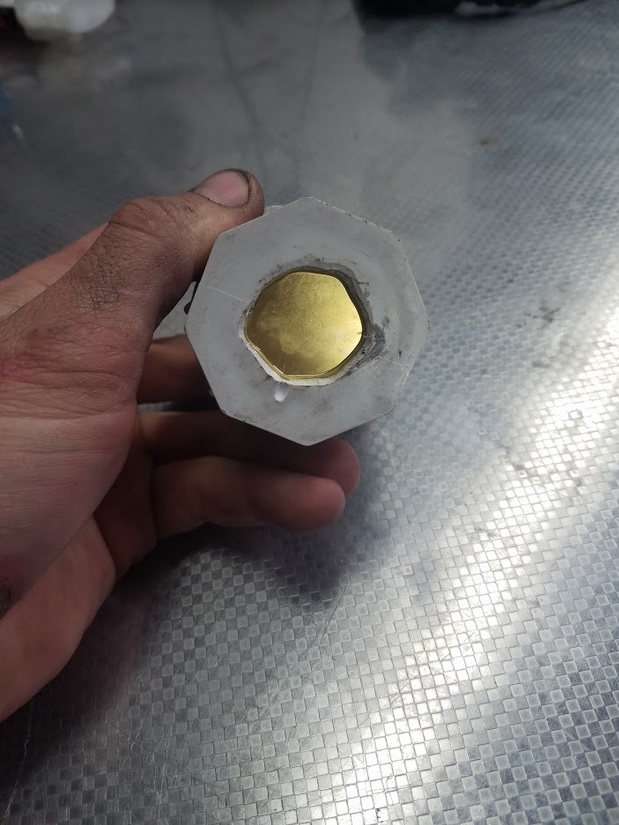

Newly re-made pressure pulse sensor

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

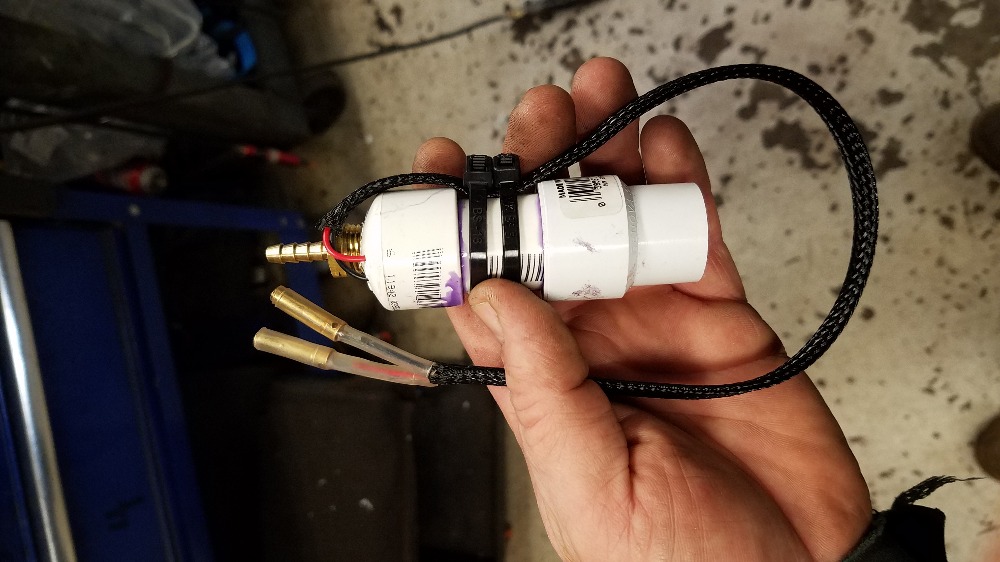

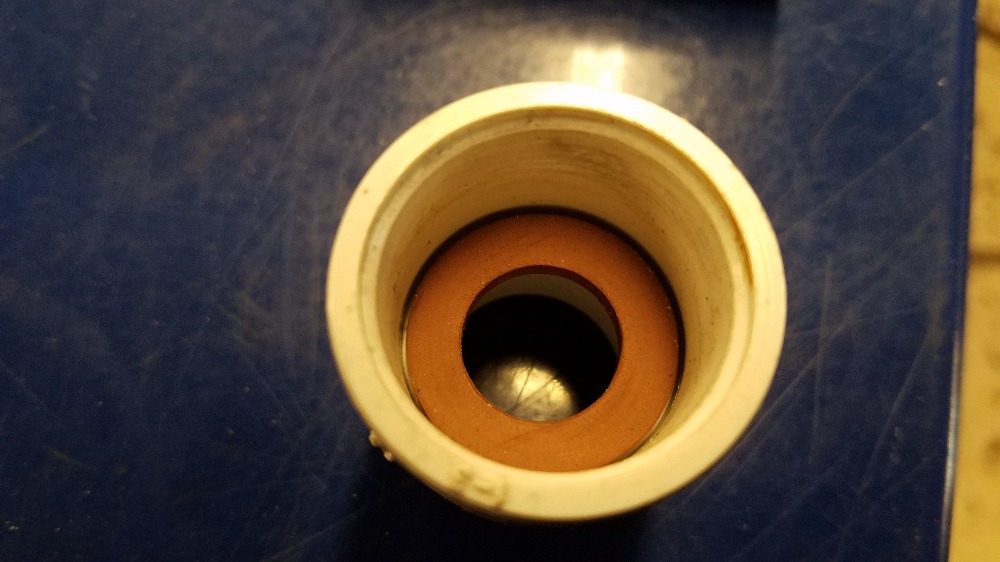

It sure is ugly, but it works! :lol: The piezo disc is glued to the bottom of this contraption. Parts courtesy of Digikey and Lowes.

I have NO idea if this matters, but I opened up the bottom so the bottom of the disc is open to atmosphere. I like to think it'll result in more sensitivity? Could be BS. :silly:

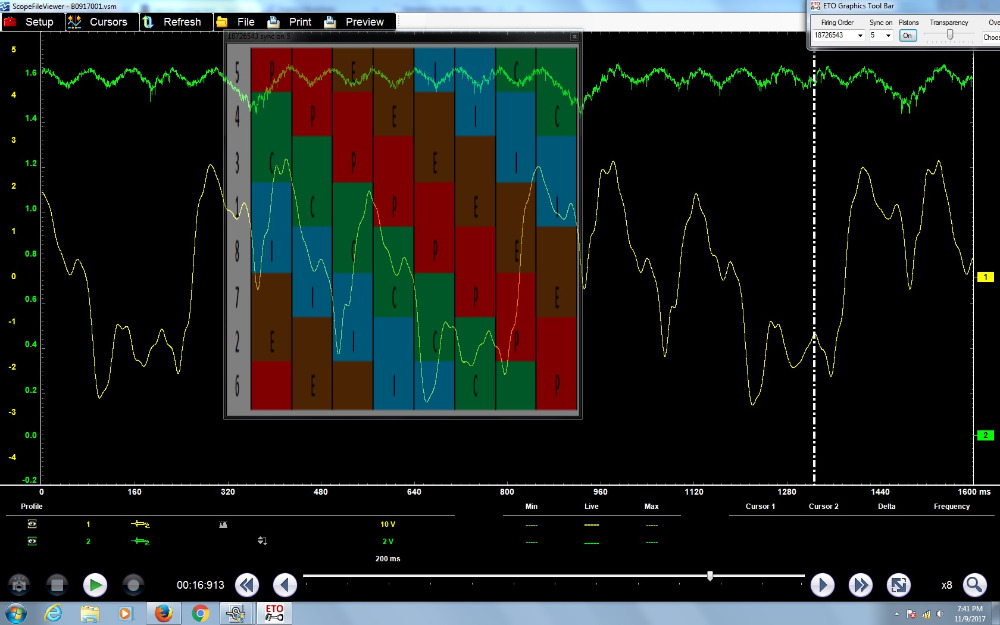

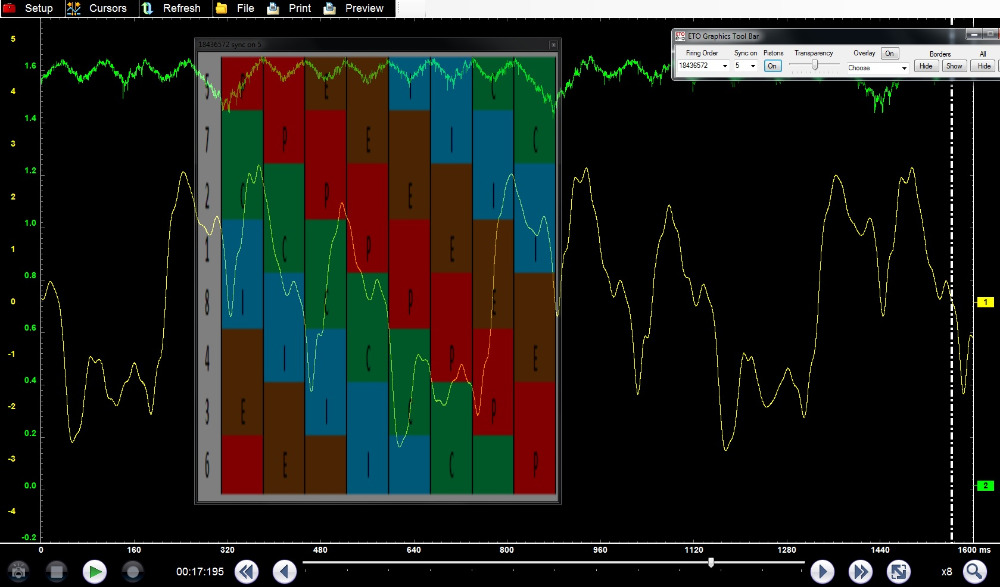

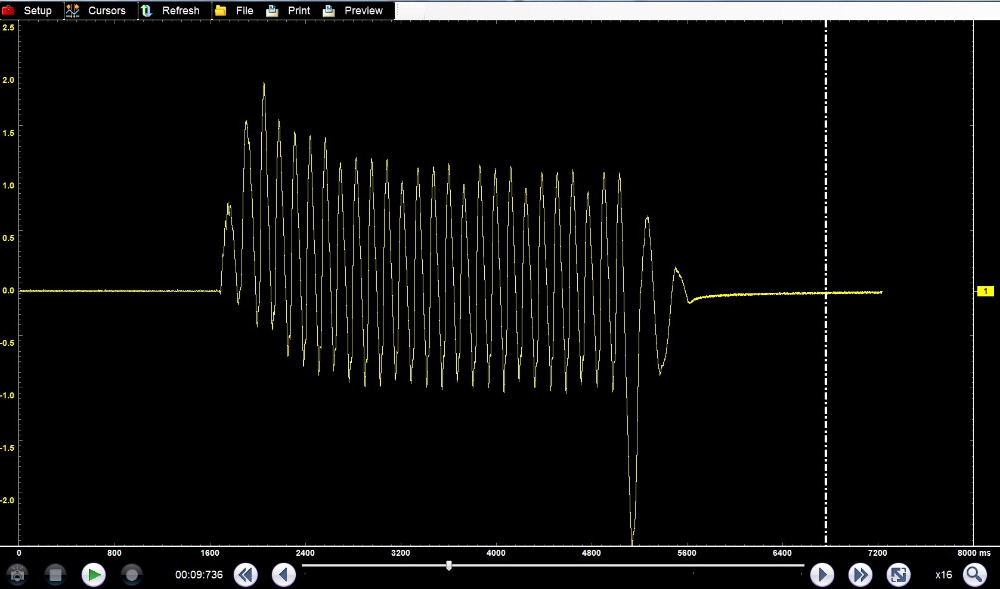

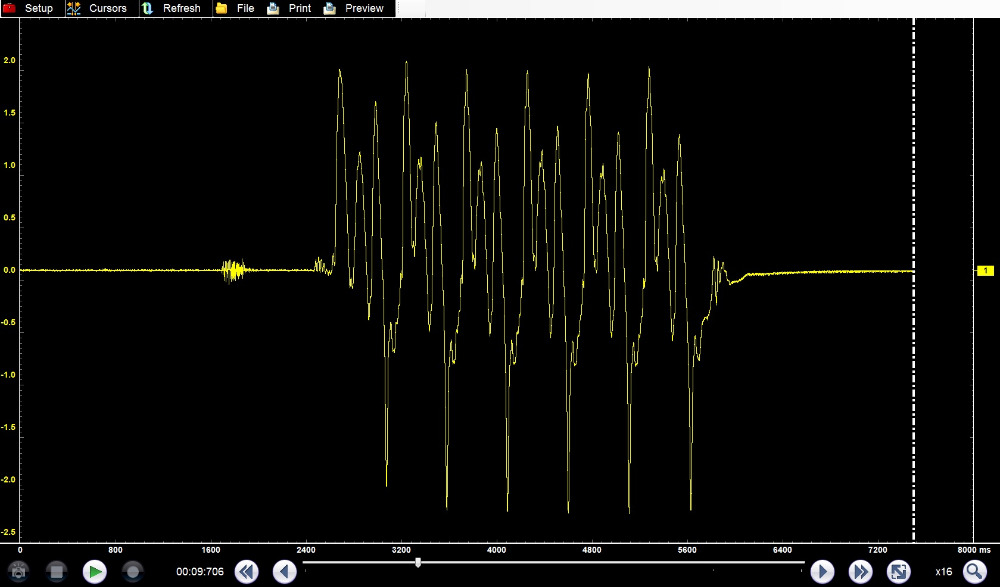

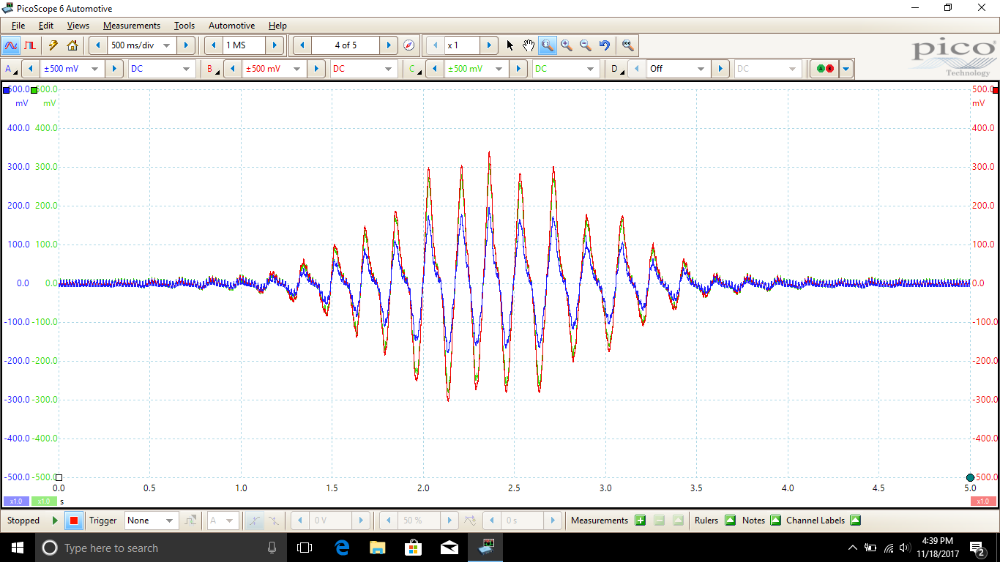

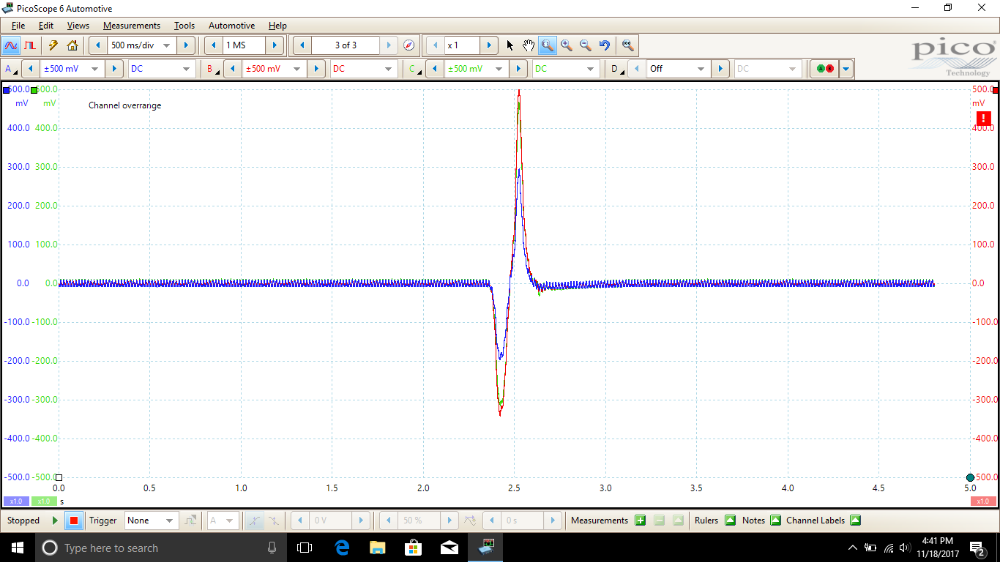

Got some waveforms off a known bad Olds Cutlass. I *think* I'm looking at a bad exhaust valve? Positive voltage is vacuum, negative is pressure.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2141

- Thank you received: 721

The positive being vacuum and negative being pressure is throwing me off, too. Can it be inverted?

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Dylan

-

- Offline

- Moderator

-

- Belgium, Europe

- Posts: 1461

- Thank you received: 327

pole71 wrote: Can you explain this, please? I'm not sure if I know what I am seeing. This is intake vacuum? In-cylinder pressure?...using the piezo disk as a pressure transducer?

The positive being vacuum and negative being pressure is throwing me off, too. Can it be inverted?

Well I have the same questions

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

EricGoodrich wrote: I wonder what kind of pressure this can handle before the crystal cracks and is unusable. And, honestly, I do not think it is ugly. I think it's a great design. Compact. Has banana jacks built in. And, if you lose it or it breaks it was inexpensive and easy to remake. Great job.

The disc is quite thin the problem with over under pressure is permanent bending of the disc. The main problem I found with mine was the wires coming off. In the end I bought an off the shelf Auto Ditex one which wasn't overly expensive. autoditex.com/pressure-pulse-sensor-63.html

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

pole71 wrote: Can you explain this, please? I'm not sure if I know what I am seeing. This is intake vacuum? In-cylinder pressure?...using the piezo disk as a pressure transducer?

The positive being vacuum and negative being pressure is throwing me off, too. Can it be inverted?

Sorry for the lack of info. :blush: It's intake vacuum pressure pulses during cranking, using the piezo disc inside the plumbing fittings. The scope trace can definitely be inverted depending on personal preference. I've just come to think of vacuum pulses as 'good', and lack of pulses or pressure as bad. As far as these waveforms go, anyway.

I wonder what kind of pressure this can handle before the crystal cracks and is unusable. And, honestly, I do not think it is ugly. I think it's a great design. Compact. Has banana jacks built in. And, if you lose it or it breaks it was inexpensive and easy to remake. Great job.

Thanks!

The disc is quite thin the problem with over under pressure is permanent bending of the disc. The main problem I found with mine was the wires coming off. In the end I bought an off the shelf Auto Ditex one which wasn't overly expensive. autoditex.com/pressure-pulse-sensor-63.html

Yeah, I figured the same. I think its use is best restricted to cranking vacuum/crankcase/exhaust stuff.

I see the Auto Ditex one can be had for around $100 - WAY more reasonable than the $400 they want for the First Look.

Also, I was an idiot and had the firing order wrong on the overlay. :blush: :silly: How did I forget the Chevy firing order? Let's try this again:

Now I wonder if it's an intake valve? :huh: It left today, so I may never know.

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

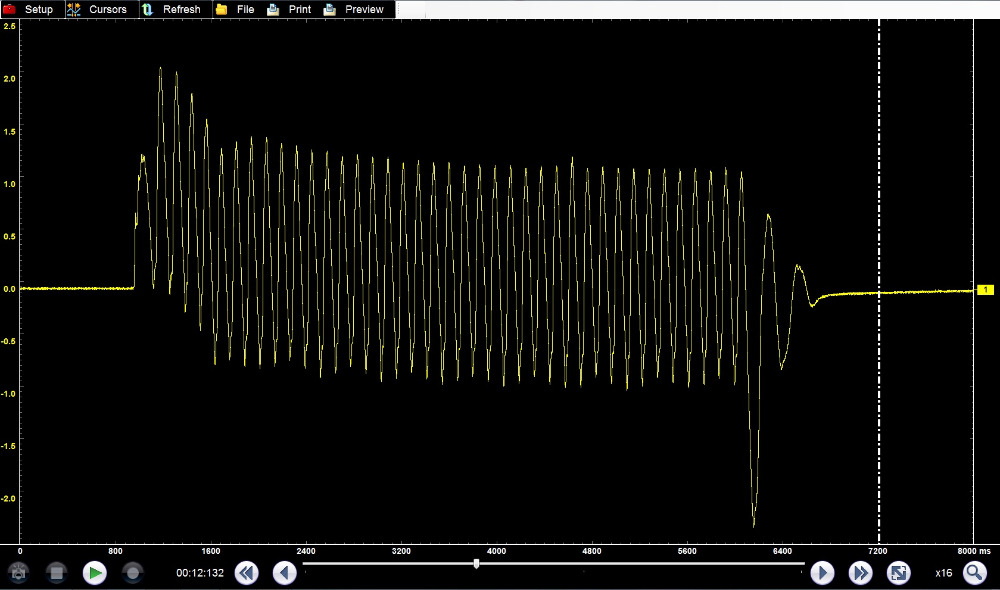

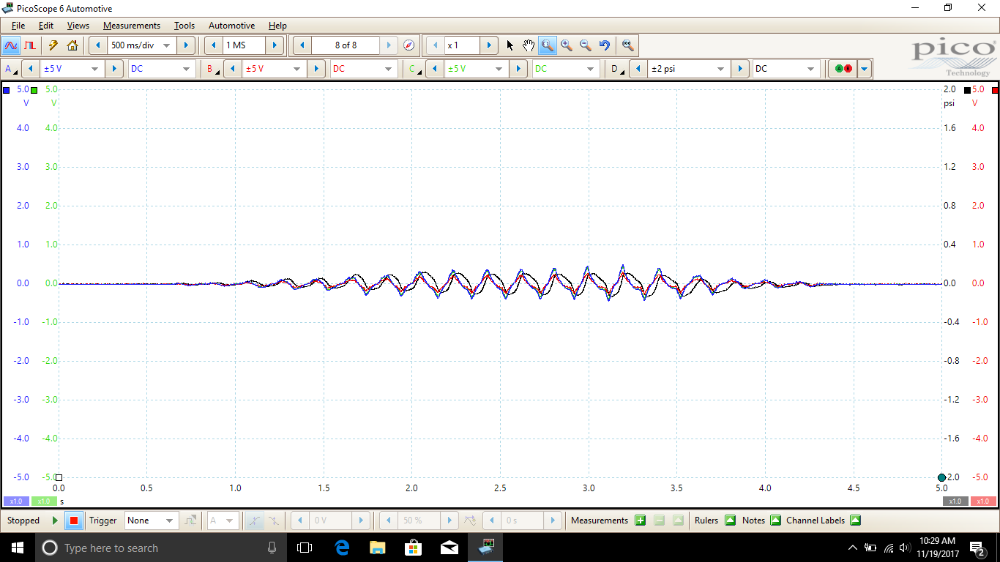

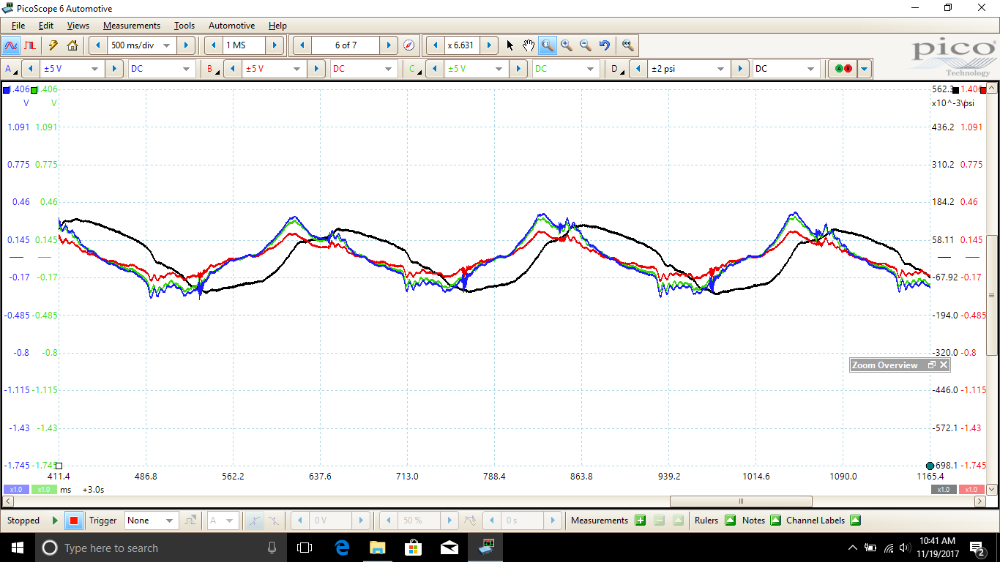

If it helps, this is a known good capture off a four cylinder:

All pulses are even and relatively uniform. This next one is with a loose plug. You can see the variance in the peaks of the pulses.

Then I took the plug out completely.

Please Log in or Create an account to join the conversation.

- bruce.oliver

-

- Offline

- Elite Member

-

- Posts: 318

- Thank you received: 88

Andy.MacFadyen wrote:

EricGoodrich wrote: I wonder what kind of pressure this can handle before the crystal cracks and is unusable. And, honestly, I do not think it is ugly. I think it's a great design. Compact. Has banana jacks built in. And, if you lose it or it breaks it was inexpensive and easy to remake. Great job.

The disc is quite thin the problem with over under pressure is permanent bending of the disc. The main problem I found with mine was the wires coming off. In the end I bought an off the shelf Auto Ditex one which wasn't overly expensive. autoditex.com/pressure-pulse-sensor-63.html

Good find. Have you used it much?

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

I've also found that their response range for sound tops out around 3khz. After that the voltage generated drops off rapidly. This was tested by using the mic to pick up sound vibrations in air. Impacts will always be picked up. For example using these for detecting knocking in engines. But steady frequencies above 3khz are a problem.

These things still kick ass though and I'm always finding new ways of using them.

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

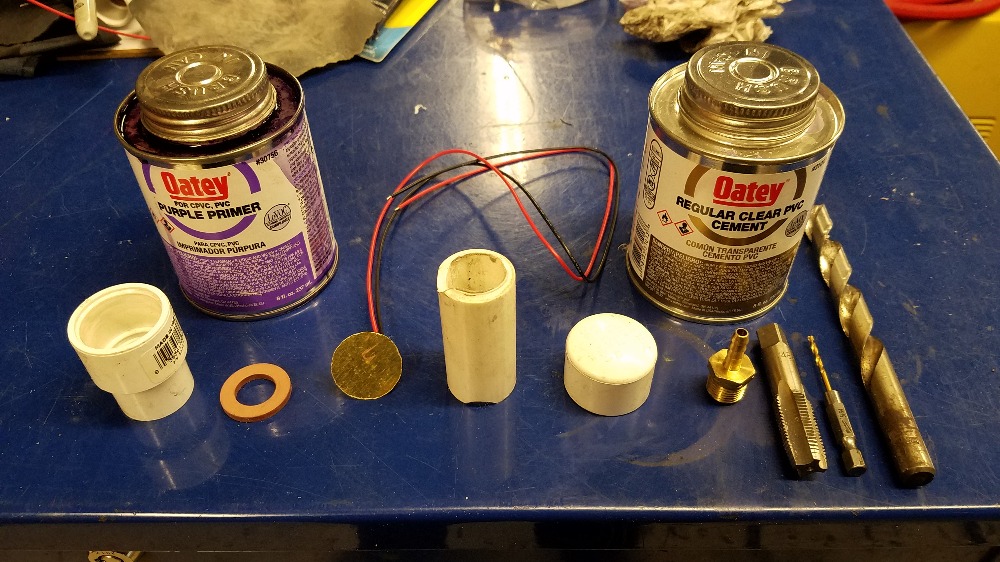

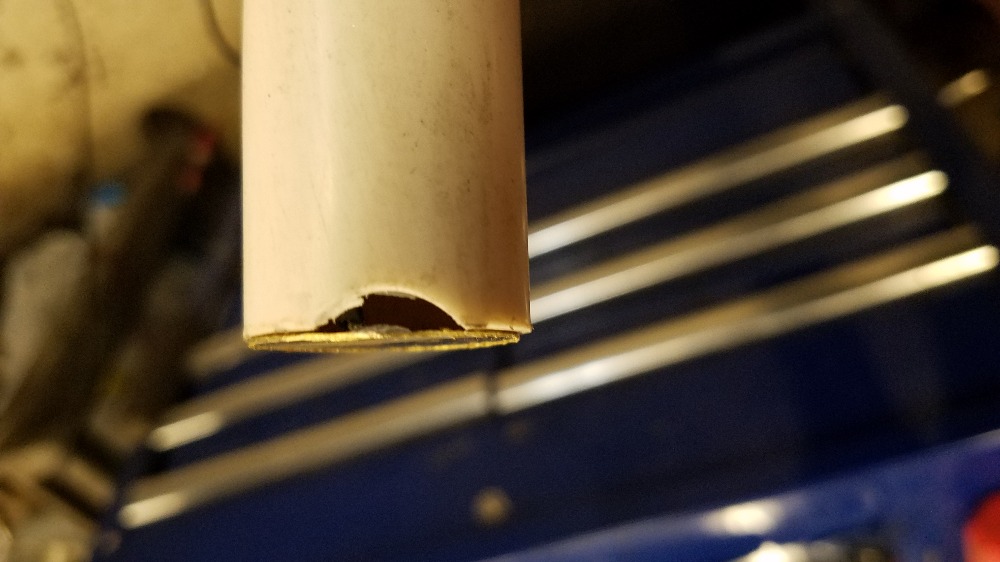

Here are all the parts I used. No glue for the disc. I used the step inside a 3/4" coupler and a rubber washer to make a seal. The bottom is open to atmosphere.

The next few photographs illustrate how is assembled.

The step inside the coupler...

Rubber washer for the disc to sit on ...

The disc sits between the end of the 3/4" pipe and the rubber washer. The notch is for the wire soldered to the disc.

One half assembled with the cap ready to go on. The wires have knots to prevent them from being disconnected from the disc if they get yanked on.

And that's it. Now to use it. I'll post some updates soon. First thing I plan on doing is sampling the same thing on three channels ( I made three of these ) and compare them for consistency.

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

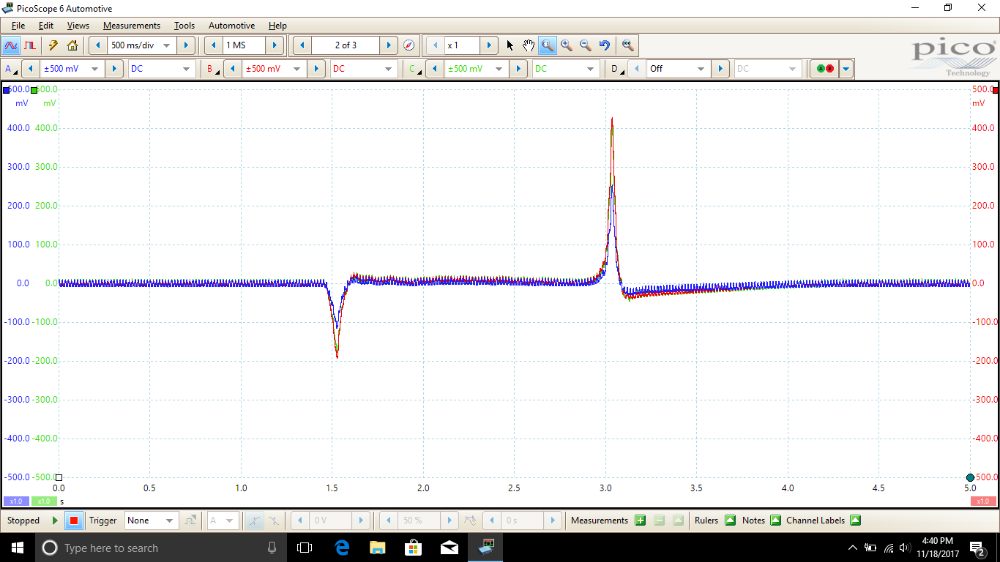

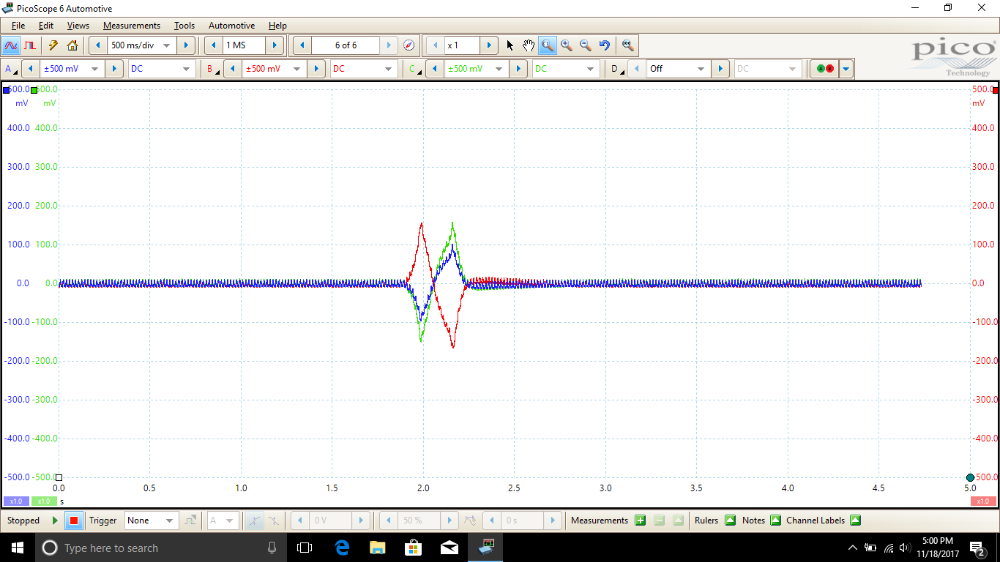

First, I pressed on the side of the bottle, rapidly and with increasing pressure and then decreasing pressure just to get an idea of how consistent they are to one another. Two of them are nearly identical while the third generates a waveform with slightly less amplitude. Still, all three create useful signals.

Next, I pressed and held, waited a moment and released. As you can see, there is a wave when the pressure is increased and held and there's a second wave when the pressure is released.

Now, just one quick press and release. Pressure rises and falls back to zero immediately. Unlike a MAP sensor, or any three wire pressure sensor, the mic is not generating a steady signal based on pressure. The mic is generating voltage as the material is deformed. This is really important because the pulses generated are not going to look like a powered sensor looks. These peizo sensors will generate a sin wave with each pressure pulse. Measuring exhaust pressure pulses, for example.

Still, awesome, cheap and effective. I'm just going to have to practice with them so I know what the hell I'm looking at.

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

This is an example with one sensor having reversed polarity. ( Plugged in backwards, ie red/black wires etc )

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

I wouldn't substitute my WPS500x pressure transducer for a peizo sensor but for less than five bucks these peizo sensors are definitely worth it. Next I'll sacrifice one of them to see how much pressure/vacuum they can take before the disc fails.

Please Log in or Create an account to join the conversation.