GDI Diagnostic Procedures

- htert2020

-

Topic Author

- Offline

- New Member

-

- Posts: 1

- Thank you received: 1

My main concern is this... There seems to be a lack of diagnostic procedures for GDI (Gasoline Direct Injection), and for solving automotive problems related to GDI.

Why is GDI so important? The reason is because half of all cars recently produced are GDI vehicles. This means that very soon, a flood of GDI related problems will be hitting professional mechanics. If you are a professional mechanic, much of your revenue and income will depend on your ability to efficiently diagnose and solve GDI related problems... assuming that you prefer being a diagnostician instead of a "parts changer".

Why is GDI diagnosis so difficult? Because:

(1) YOU CANNOT INSERT YOUR OWN PRESSURE GAUGE into the high-pressure fuel rail. This means you have to rely on the pressure sensor that is already on the fuel rail, which cannot be fully trusted because it has been exposed to heat, weather, and abuse from the rigors of daily driving. Ideally, you would want to insert your own pressure gauge into the high-pressure fuel rail or pipe, since you know and trust your own pressure gauge. But vehicle manufacturers make it impractical or impossible to do so.

(2) DISPOSABLE STEEL PIPES must be replaced everytime they are disconnected for any reason, including diagnostic reasons. This means that you will have to charge the customer for a brand new steel pipe, just for performing a diagnosis that requires you to remove a component for inspection or bench testing. If you need to inspect the camshaft lobe for possible wear, you will need to remove the high-pressure fuel pump, which may require you to disconnect the steel pipe leading to the fuel rail. And if you need to perform this diagnostic procedure multiple times, for whatever reason, you will need to replace the steel pipe multiple times.

(3) BENCH TESTING COMPONENTS IS IMPRACTICAL because you would have to reproduce the super high fuel pressures on your bench laboratory in order to reliably test a component such as a high pressure fuel pump, fuel injector, or pressure sensor.

For example, consider a vehicle that has the trouble code P0087 (Fuel Rail/System Pressure - Too Low). There are several possible causes for this:

(a) Faulty high-pressure fuel pump.

(b) Faulty low-side fuel pressure.

(c) Faulty electrical circuit control signals entering the solenoid part of the high-pressure fuel pump.

(d) Faulty camshaft lobe (worn out).

(e) Faulty tappet roller/follower on top of the camshaft lobe.

(f) Faulty camshaft timing, which might cause the PCM control signals to the solenoid to be out-of-sync with the pump's piston movement.

(g) Faulty pressure sensor on the fuel rail reporting a false low-pressure reading.

How would you definitively pinpoint the root cause of this problem without removing a single component, without disconnecting the steel pipe, without inserting your own pressure gauge? Can you develop a formal diagnostic procedure that can powerfully arrive at the correct diagnosis -- each and everytime?

Of course, you can test the low-side fuel pressure by inserting your own pressure gauge on the low-side. Of course, you can test the electrical control signals entering the solenoid part of the high-pressure fuel pump. Of course, you can test the electrical wiring between the fuel rail pressure sensor and the PCM. Of course, you can test the camshaft timing by looking at an in-cylinder pressure waveform on an oscilloscope.

But beyond those tests, there is little else that you can do. If the root cause of the problem cannot be identified by any of those tests, then you are out of luck. You will then have to disconnect components for visual inspection or bench testing, which will be costly to the customer.

Another type of GDI related problem is faulty fuel injectors. Most scan tools allow you to run an injector balance test. However, this test requires the use of data from the fuel rail pressure sensor. Here, you are being asked to have complete faith and trust in the pressure sensor already installed on the vehicle. You are also being asked to have complete faith and trust in the control signals from the PCM to the fuel injectors. Computers and electrical wires under the hood of a vehicle are vulnerable to breakdown because of the harsh environments that they are exposed to on a daily basis. This is why performing a manual injector balance test is the most reliable way to test fuel injectors (other than bench testing them). Manual injector balance tests require you to insert your own pressure gauge (which you know and trust), and to provide your own electrical device that sends the control signals to the injectors. But you cannot perform manual injector balance tests on a GDI system. The high pressures and disposable steel pipes in a GDI system mean that all injector balance testing must be done through the vehicle's computer... which is vulnerable to breakdown because of their harsh environments.

Overall, I find that GDI testing is inherently difficult... for the very reasons stated above. I have yet to develop a complete diagnostic procedure or flowchart that can powerfully solve all GDI related problems. And Scanner Danner's book does not provide any solutions either.

If anyone has any ideas or suggestions for GDI diagnostic procedures, please let me know... Not just for my benefit, but for the benefit of other people here on this forum. Thanks.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1114

It just goes to show how quickly things change. There's sections in the book referring to mechanical mass air flow meters and single wire oxygen sensors, because that's what he was working on when writing his manual.

I don't disagree with you however. Along with GDI testing, some AFR testing and CAN network testing would be a welcome update in later versions. (Until the next disruptive technology makes that knowledge obsolete as well).

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

My main concern is this... There seems to be a lack of diagnostic procedures for GDI (Gasoline Direct Injection), and for solving automotive problems related to GDI.

Hey htert202, welcome to the forums! I would generally agree that diagnosing GDI issues isn't very well understood in aftermarket shops. There's training material out there, but it's not always great quality, and sometimes difficult to access.

(1) YOU CANNOT INSERT YOUR OWN PRESSURE GAUGE

This may be down to my experience, but I generally find high pressure sensors to be extremely reliable, on all makes/models. I can really only recall one high pressure sensor that was misreporting. I rarely catch myself thinking that I wish I could install my own high pressure gauge.

(2) DISPOSABLE STEEL PIPES

Sucks that the job is more expensive because of the disposable pipe, sure. But you didn't break it, build it or buy it. You're just trying to fix it.

As an example for anyone else following along, I can go through a GDI concern I saw earlier this year.For example, consider a vehicle that has the trouble code P0087 (Fuel Rail/System Pressure - Too Low). There are several possible causes for this

...

If anyone has any ideas or suggestions for GDI diagnostic procedures, please let me know... Not just for my benefit, but for the benefit of other people here on this forum. Thanks.

2012 Sorento 2.4L, came in with a complaint of low power and MIL. It had exactly the code you took as an example, P0087 Fuel Rail Pressure Too Low. Engine has a long crank time and low power, just like the owner stated.

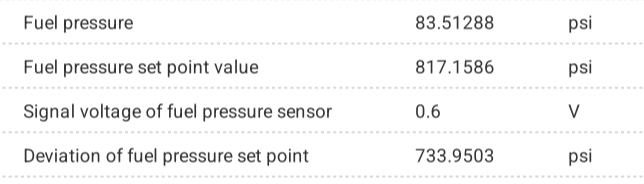

Scan data showed this:

Actual rail pressure is 83 PSI, desired is 817 PSI. So the high pressure pump isn't working. The high pressure pump needs low side pressure, a mechanical connection to the cam lobe and solenoid control to work.

I can be reasonably sure the low side pump is working, because 83 PSI is a reasonable value for the low side system. That also means the high pressure sensor is likely telling the truth. If the actual high side pressure was higher than 83 PSI, the engine probably wouldn't have a long crank. If it was closer to zero, the engine probably wouldn't be starting at all.

Amp clamp on the solenoid control wire shows good circuit current. After that, all that's left is the camshaft and the follower. Engine isn't noisy, engine oil doesn't have glitter in it. I sell the high pressure pump and a careful explanation that any damage found to the camshaft or follower will require additional repairs. High pressure pump fixed it.

Is the above a 110% accurate diag? No, the camshaft is a loose end. But It's pretty thorough, doesn't require gauge installation and has no unnecessary disassembly.How would you definitively pinpoint the root cause of this problem without removing a single component, without disconnecting the steel pipe, without inserting your own pressure gauge? Can you develop a formal diagnostic procedure that can powerfully arrive at the correct diagnosis -- each and everytime?

In my experience, in a repair shop environment, this is about as good as it's gonna get. You could pull the high pressure pump for a visual, sure, but what happens when you find no camshaft damage? You can let the car sit in your bay while the customer doesn't answer their phone. Or, you can put it back together and hope you make the time back doing the repair. If the customer buys it at all. They may price shop you and take it down the road.

Another type of GDI related problem is faulty fuel injectors. Most scan tools allow you to run an injector balance test. However, this test requires the use of data from the fuel rail pressure sensor. Here, you are being asked to have complete faith and trust in the pressure sensor already installed on the vehicle.

I completely agree with your lack of trust in scan tool injector balance tests, but for different reasons. My experience with performing the balance test before and after injector replacement shows that the tests themselves just don't have the consistency needed to accurately ID a problem injector.

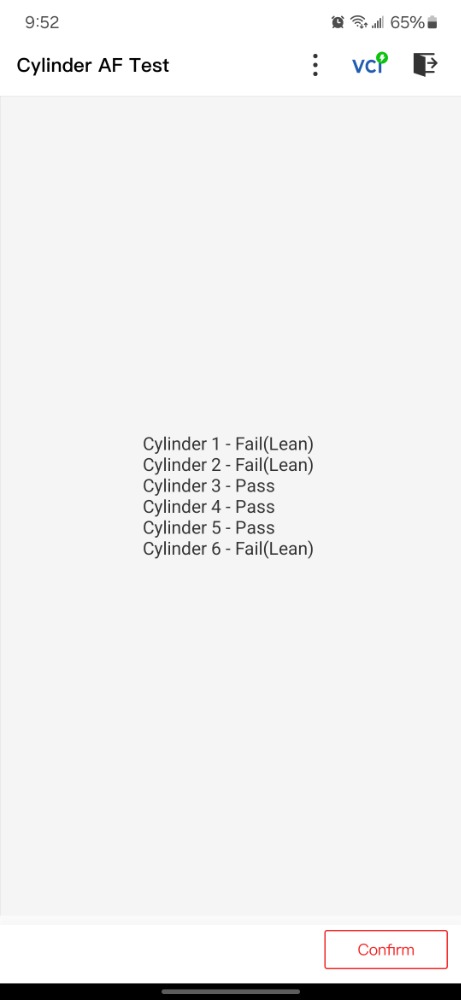

As an example, this '17 Pilot 3.5L came in with a P219B Air/Fuel Imbalance Bank 2. There's an injector balance test (Cylinder A/F) available, and it generated this:

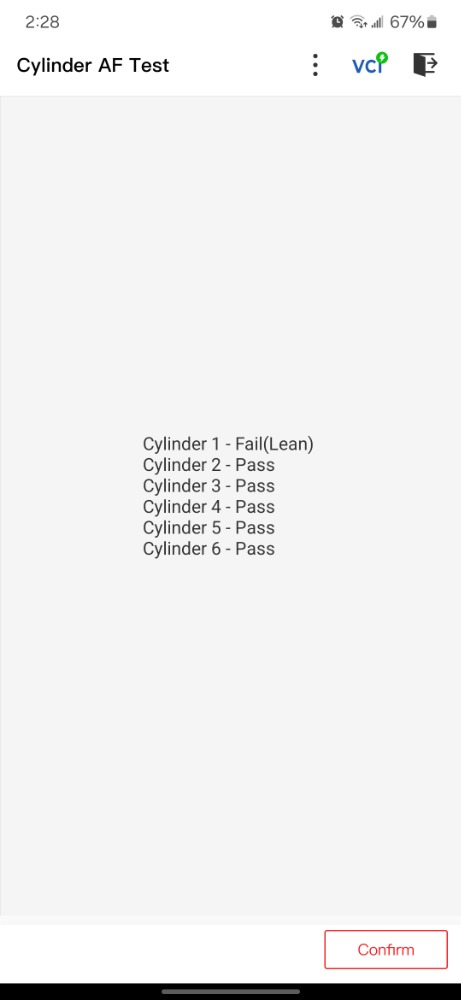

Sure looks like there's some issues, right? After I put a set of Honda injectors in it, I reran the test and got this:

So, my new OE injector is bad? Test drove multiple times, no fault codes came back. I feel pretty confident I fixed the P219B, so I can only assume that the test itself just... sucks. Plus, my understanding of the Cylinder A/F test is that the results aren't based on the high pressure rail sensor readings, but on the upstream air/fuel sensor.

I don't mean to sound contrary, but you can actually do manual balance testing on GDI vehicles. Bernie Thompson had a great example of a manual test in one of his videos:But you cannot perform manual injector balance tests on a GDI system. The high pressures and disposable steel pipes in a GDI system mean that all injector balance testing must be done through the vehicle's computer... which is vulnerable to breakdown because of their harsh environments.

Bernie used his ATS scope for the balance tester, but a good ol' OTC injector buzz tester will work just as well.

Of course, just because you CAN do this test doesn't mean it's a good idea, or even a good test. Getting to the module or injector wires on a given vehicle may be miserable. Plus, even if the manual balance test shows no issues, that doesn't mean the injectors are good.

Please Log in or Create an account to join the conversation.

- Farseer

-

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 5

If you have any more GDI case studies, please write them in a similar way! I would love to see them.

P.S. I know this isn't supposed to be the right way, but I've disconnected those so-called "disposable" fuel lines many times and nothing has ever happened... So I think that may be an exaggeration.

Please Log in or Create an account to join the conversation.