A place to discuss hardware/software and diagnostic procedures

P0300 Following Engine Maintenance

- eengstrom

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

1 year 5 months ago #66628

by eengstrom

P0300 Following Engine Maintenance was created by eengstrom

We are a new but growing shop in California. I wanted to share a perfect example of how it's not just enough to have access to the data in a vehicle, but that understanding how all of the data comes together and what it SHOULD be in relation to other data is fundamental to being good at diagnostic evaluation.

We support the State Park Ranger and Lifeguards nearest our shop. One of their vehicles is a 2013 Chevy Tahoe 4WD with 116,000 miles. We recently conducted misfire and lean code repairs (bread and butter, "engine maintenance I"), gaskets, intake manifold gaskets, plugs, wires, oil and air. We noticed the trim was great at idle and the test drive cleared the vehicle to return to service. 27.7 miles (3 days later) the vehicle is exhibiting P0300.

Customer's concerns were: intermittent problems with acceleration (never the same), rough idle at stop (not always), no misfires on cold start and the check engine light comes and goes. Vehicle has 300 miles after service for the other problems with lean condition misfiring.

Visual inspection showed no issues with the prior service. Fuel trim averages are 0-4% and the short term data looked good. O2 are responsive and coming online. Misfire was random, but mostly centered on 1, 3, and 8. Misfires were utterly random across RPM.

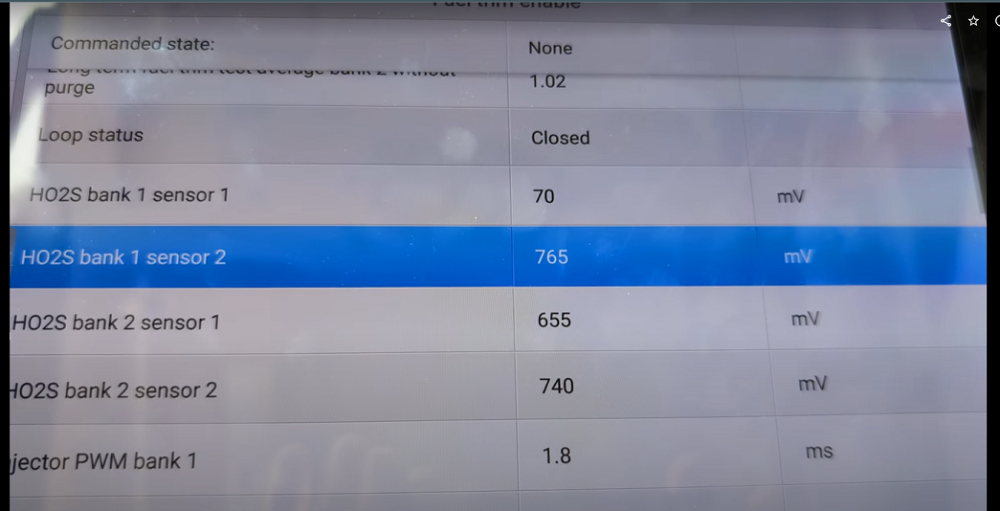

Used an Autel Ultra Elite VCI tool to check live data, switched into tests and brought up Fuel Trim monitors. The O2s on any vehicle can still be responding, trims can still gather and adjust in the ECU, and voltage can read ok at the connector. REMEMBER: You have to check the signal, too, as Paul remarks every now and again. In the BMW engine management world, our tools use the terminology of "PLAUSIBLE" and "IMPLAUSIBLE". If you understand the O2 ranges, you'd know this is an IMPLAUSIBLE reading of the fuel trim signal. I sure with the GM engineers would add that feature.

In this screenshot and capture, you'll see that the downstream sensors aren't moving very much. They actually don't move much at all, a symptom they are unresponsive and need to be replaced. The upstream O2 sensors move too much, and they move in an implausible manner, jumping between a measurement that is too low (below 100 millivolt is out of bounds) and very high. This is causing the engine management computer to sometimes hiccup the injector and timing functions. We also noted but not shown on this screen that the Engine's calculated load temperature in Farenheit was somewhere over 743f, which isn't plausible either.

Check this video link to Google Photos: photos.app.goo.gl/KprsSM7rPapHkSgp9

Enjoy and remember to check your

We support the State Park Ranger and Lifeguards nearest our shop. One of their vehicles is a 2013 Chevy Tahoe 4WD with 116,000 miles. We recently conducted misfire and lean code repairs (bread and butter, "engine maintenance I"), gaskets, intake manifold gaskets, plugs, wires, oil and air. We noticed the trim was great at idle and the test drive cleared the vehicle to return to service. 27.7 miles (3 days later) the vehicle is exhibiting P0300.

Customer's concerns were: intermittent problems with acceleration (never the same), rough idle at stop (not always), no misfires on cold start and the check engine light comes and goes. Vehicle has 300 miles after service for the other problems with lean condition misfiring.

Visual inspection showed no issues with the prior service. Fuel trim averages are 0-4% and the short term data looked good. O2 are responsive and coming online. Misfire was random, but mostly centered on 1, 3, and 8. Misfires were utterly random across RPM.

Used an Autel Ultra Elite VCI tool to check live data, switched into tests and brought up Fuel Trim monitors. The O2s on any vehicle can still be responding, trims can still gather and adjust in the ECU, and voltage can read ok at the connector. REMEMBER: You have to check the signal, too, as Paul remarks every now and again. In the BMW engine management world, our tools use the terminology of "PLAUSIBLE" and "IMPLAUSIBLE". If you understand the O2 ranges, you'd know this is an IMPLAUSIBLE reading of the fuel trim signal. I sure with the GM engineers would add that feature.

In this screenshot and capture, you'll see that the downstream sensors aren't moving very much. They actually don't move much at all, a symptom they are unresponsive and need to be replaced. The upstream O2 sensors move too much, and they move in an implausible manner, jumping between a measurement that is too low (below 100 millivolt is out of bounds) and very high. This is causing the engine management computer to sometimes hiccup the injector and timing functions. We also noted but not shown on this screen that the Engine's calculated load temperature in Farenheit was somewhere over 743f, which isn't plausible either.

Check this video link to Google Photos: photos.app.goo.gl/KprsSM7rPapHkSgp9

Enjoy and remember to check your

Please Log in or Create an account to join the conversation.

Time to create page: 0.255 seconds