A place to discuss hardware/software and diagnostic procedures

In cylinder compression waveform help please

- dannydebont

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

1 year 8 months ago #65813

by dannydebont

In cylinder compression waveform help please was created by dannydebont

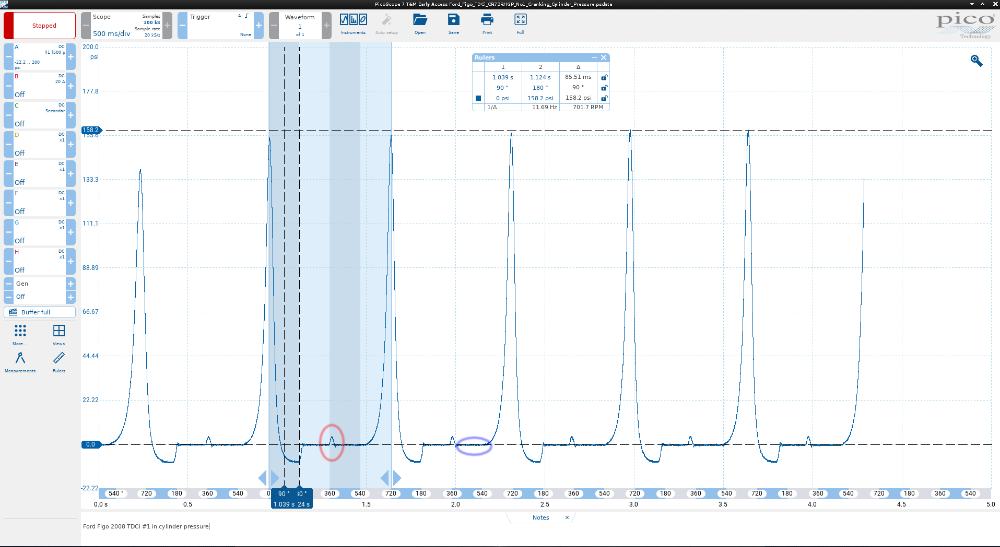

I did an in cylinder pressure test on a Ford Figo TDci (diesel) 2008 F6J6 engine. The engine is out of the car with all ancillaries removed except for the starter motor and fuel pump. The intake box, E.G.R system are all removed. The injectors and glow plugs are still fitted to the engine with the turbo. I modified an old glow plug to measure pressures.

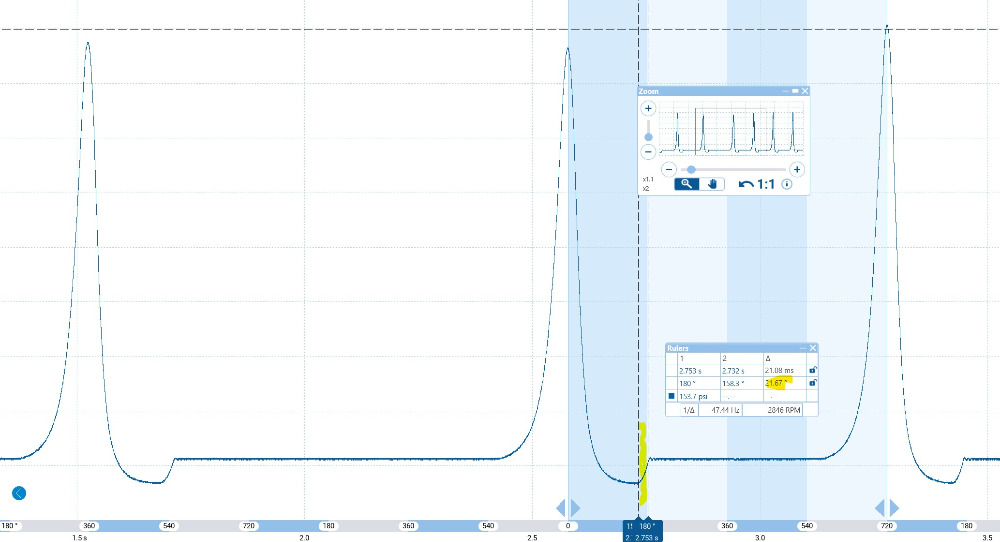

When I crank the engine I get a nice waveform except for a bump at the bottom of the (exhaust stroke) plateau (red circle). This is when the piston has reached BDC (180°), and starts to move towards the cylinder head reducing the volume of the cylinder, but since the exhaust valve is now open, the gas charge escapes into the exhaust. So the plateau represents the time during which the piston is pushing exhaust gas out and during this time the pressure in the cylinder should be nearly equal to the atmospheric pressure.

But as you can see on the attachment there is a bit of a bump just when the exhaust valve closes (4.1psi) and no vacuum on the intake stroke.

Also, the Ford manual states that the difference between the cylinder pressures should not be more than 5 bar but says nothing about what the pressure should be. #1, #2 and #3 pressures are almost exactly the same (158 psi), however #4 is 192 psi.

I have the same hump on #1, #2, and #4 cylinders except for #3 which do not have the hump and no intake vacuum pocket.

When I crank the engine I get a nice waveform except for a bump at the bottom of the (exhaust stroke) plateau (red circle). This is when the piston has reached BDC (180°), and starts to move towards the cylinder head reducing the volume of the cylinder, but since the exhaust valve is now open, the gas charge escapes into the exhaust. So the plateau represents the time during which the piston is pushing exhaust gas out and during this time the pressure in the cylinder should be nearly equal to the atmospheric pressure.

But as you can see on the attachment there is a bit of a bump just when the exhaust valve closes (4.1psi) and no vacuum on the intake stroke.

Also, the Ford manual states that the difference between the cylinder pressures should not be more than 5 bar but says nothing about what the pressure should be. #1, #2 and #3 pressures are almost exactly the same (158 psi), however #4 is 192 psi.

I have the same hump on #1, #2, and #4 cylinders except for #3 which do not have the hump and no intake vacuum pocket.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

Less

More

- Posts: 2146

- Thank you received: 723

1 year 8 months ago - 1 year 8 months ago #65814

by Chad

Cranking RPM is so slow that there is plenty of time for air to rush into the cylinder during the intake stroke. Because of this, there is very little, if any, noticeable vacuum so be seen during the intake stroke. This is, also, normal.

When the engine is running, however, the piston is moving faster than the air can flow, causing a noticeable vacuum.

If you want to see an intake event while cranking, block the intake to restrict the the amount of air that can enter the intake manifold.

1. An intake valve closing early.

2. Excessive Carbon build-up in the cylinder.

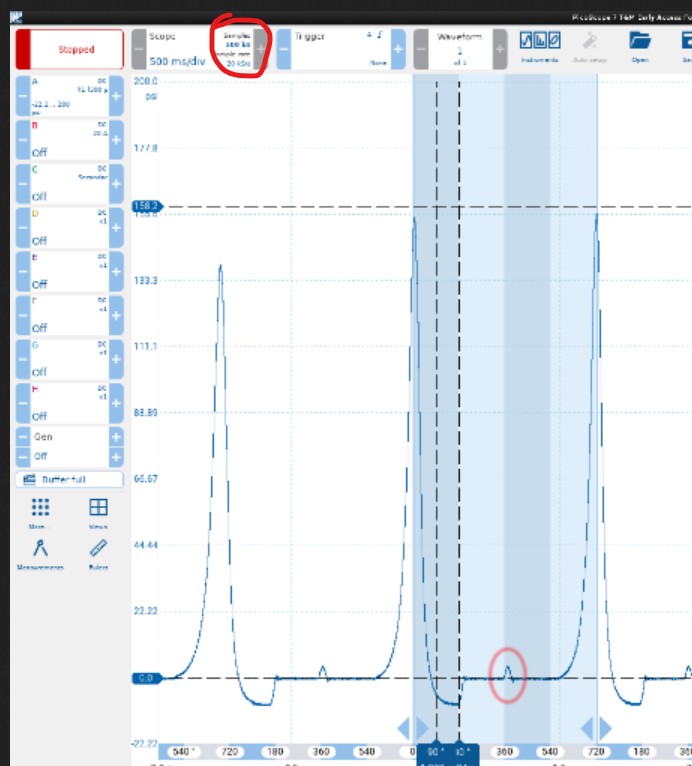

Due to the zoom level of your image, it's hard to tell for sure, but it looks like you may have a "leaning" compression tower. It, also, looks like the "little hump" on the exhaust stroke is occurring AFTER TDC, according to the position of your 720° cursors. These two things suggest that you may be losing compression before TDC. I would increase the sample rate of your scope to 1MS/s, set the time-base to 1 second per division (a 10 second screen), and recapture with a long, 10 second crank.

If you capture more waveforms, share the .psdata files, please.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Replied by Chad on topic In cylinder compression waveform help please

I am not very familiar with Diesel engines but, the little hump at the end of the exhaust stroke is normal on a turbo-charged engine. On a non-turbo engine, I would suspect that the exhaust valve closed a little early.When I crank the engine I get a nice waveform except for a bump at the bottom of the (exhaust stroke) plateau (red circle).

and no vacuum on the intake stroke.

Cranking RPM is so slow that there is plenty of time for air to rush into the cylinder during the intake stroke. Because of this, there is very little, if any, noticeable vacuum so be seen during the intake stroke. This is, also, normal.

When the engine is running, however, the piston is moving faster than the air can flow, causing a noticeable vacuum.

If you want to see an intake event while cranking, block the intake to restrict the the amount of air that can enter the intake manifold.

A couple things that can make a cylinder have higher compression are:#1, #2 and #3 pressures are almost exactly the same (158 psi), however #4 is 192 psi.

1. An intake valve closing early.

2. Excessive Carbon build-up in the cylinder.

I would block the throttle body intake, (to make more definition in the intake stroke), and capture a waveform of each cylinder. You can, then, lay them on top of each other to compare valve timings.I have the same hump on #1, #2, and #4 cylinders except for #3 which do not have the hump and no intake vacuum pocket.

Due to the zoom level of your image, it's hard to tell for sure, but it looks like you may have a "leaning" compression tower. It, also, looks like the "little hump" on the exhaust stroke is occurring AFTER TDC, according to the position of your 720° cursors. These two things suggest that you may be losing compression before TDC. I would increase the sample rate of your scope to 1MS/s, set the time-base to 1 second per division (a 10 second screen), and recapture with a long, 10 second crank.

If you capture more waveforms, share the .psdata files, please.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Last edit: 1 year 8 months ago by Chad.

Please Log in or Create an account to join the conversation.

- dannydebont

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

1 year 8 months ago #65815

by dannydebont

Replied by dannydebont on topic In cylinder compression waveform help please

Thank you for the reply. Your explanation on the absence of an intake vacuum pocket makes sense. I have included the psdata files (Just rename them back to .psdata)

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

Less

More

- Posts: 2146

- Thank you received: 723

1 year 8 months ago #65816

by Chad

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Replied by Chad on topic In cylinder compression waveform help please

Files received. I will overlay the waveforms later, today. Here is a link to the .psdata files, if anyone else is interested.

drive.google.com/drive/folders/1Cpa_Rhdx...vDtUKyxM?usp=sharing

drive.google.com/drive/folders/1Cpa_Rhdx...vDtUKyxM?usp=sharing

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

Less

More

- Posts: 2146

- Thank you received: 723

1 year 8 months ago #65819

by Chad

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Replied by Chad on topic In cylinder compression waveform help please

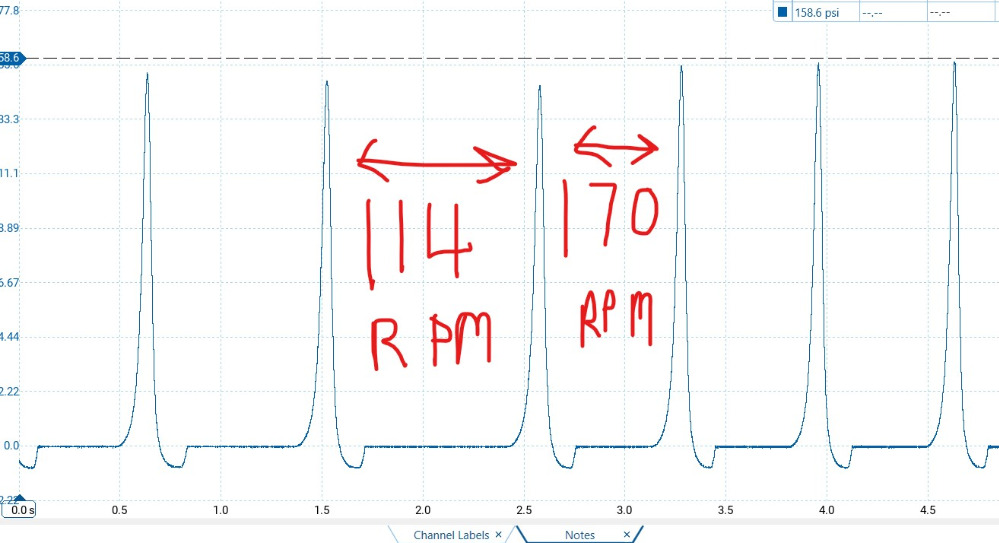

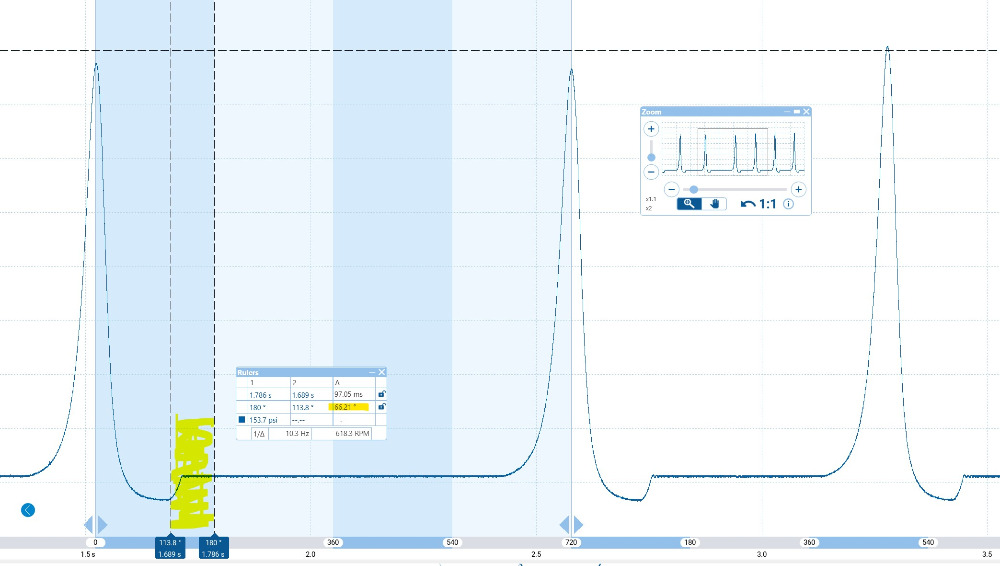

Looking at the waveforms, Cylinder #3 is definitely the "odd-man-out".

The time-base of the captures is a little low, though. With only 5 seconds on the screen and cranking speed, there is only 6 compression events. That is not enough time for the cranking speed to stabilize. I can see on cylinder #3 that it has a drastic change in RPM, from one revolution to the next.

This makes comparing valve events very difficult. This image show a 70 RPM and 25° EVO difference, from one cycle, to the next.

If you can, re-capture with 10 seconds of cranking. Be sure to have a fully charged battery, so that cranking speed is consistent.

The time-base of the captures is a little low, though. With only 5 seconds on the screen and cranking speed, there is only 6 compression events. That is not enough time for the cranking speed to stabilize. I can see on cylinder #3 that it has a drastic change in RPM, from one revolution to the next.

This makes comparing valve events very difficult. This image show a 70 RPM and 25° EVO difference, from one cycle, to the next.

If you can, re-capture with 10 seconds of cranking. Be sure to have a fully charged battery, so that cranking speed is consistent.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- dannydebont

-

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

1 year 8 months ago #65825

by dannydebont

Replied by dannydebont on topic In cylinder compression waveform help please

I will re-capture with a longer time period and post the files here

Please Log in or Create an account to join the conversation.

Time to create page: 0.366 seconds