Kia engine going knock-knock-knock

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

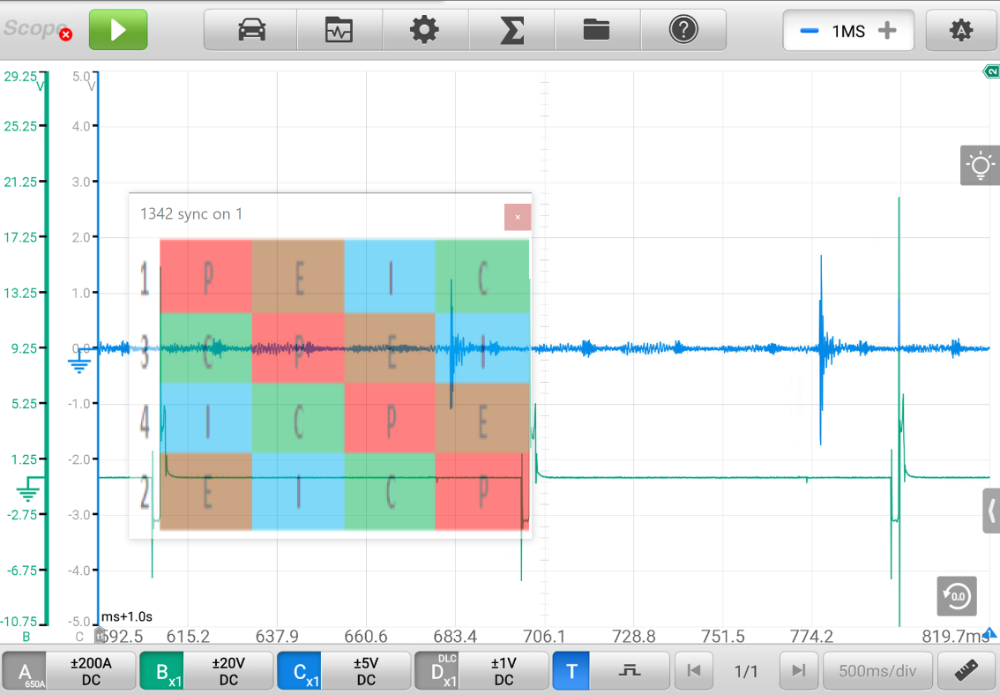

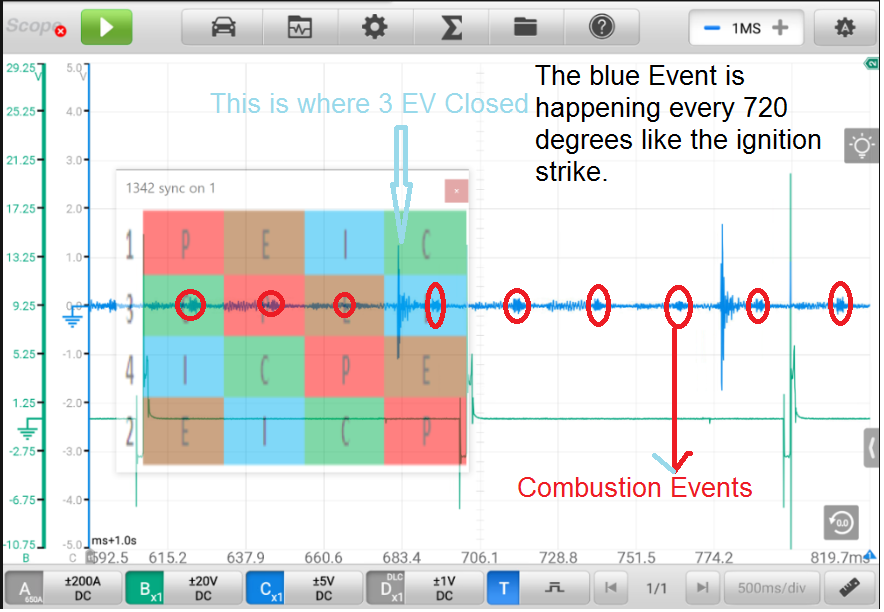

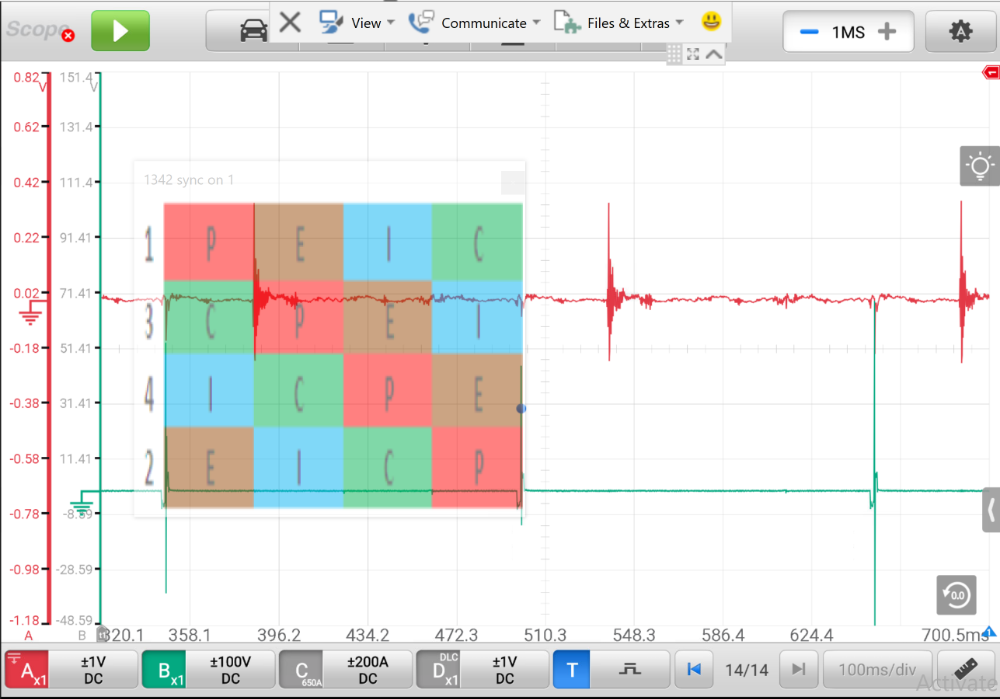

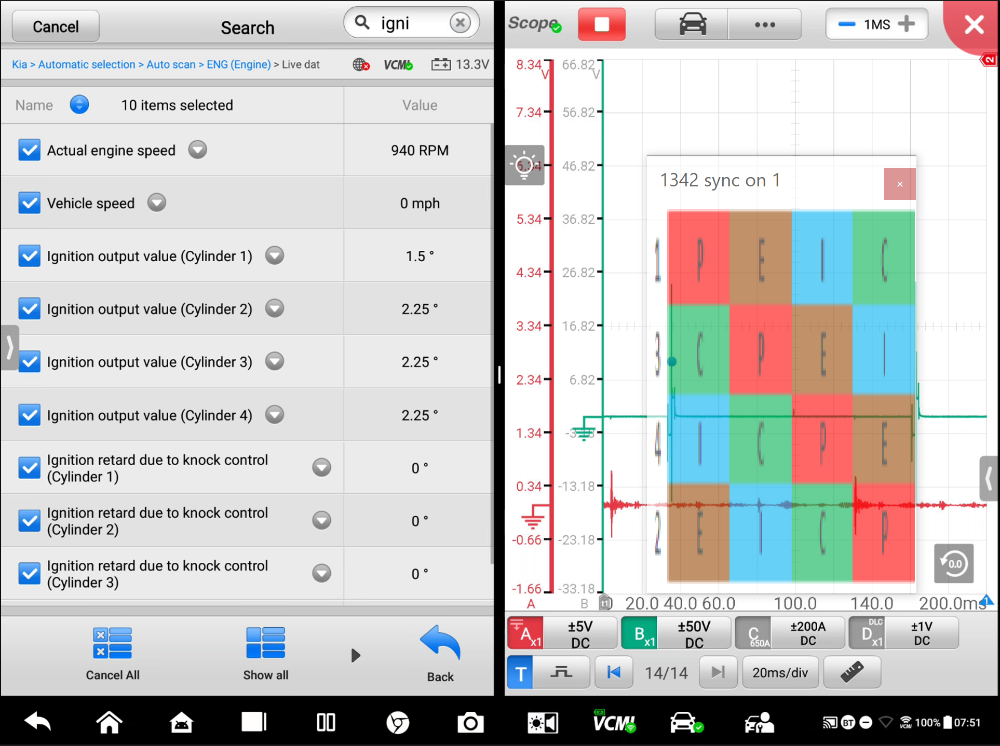

I've been playing with making use of a Jaguar knock sensor as a diagnostic tool to narrow down engine noises. It's a bit academic - most engines with severe noises also have glitter in the oil and need long blocks - but I still think it's useful to stay in practice. The most recent example was a '16 Kia Soul with a very audible engine noise, particularly off idle. My scope connections look like this:

Sync on #1, knock sensor directly on the head. It's really nice of Kia to provide these cylinder head flanges to bolt my sensor to!

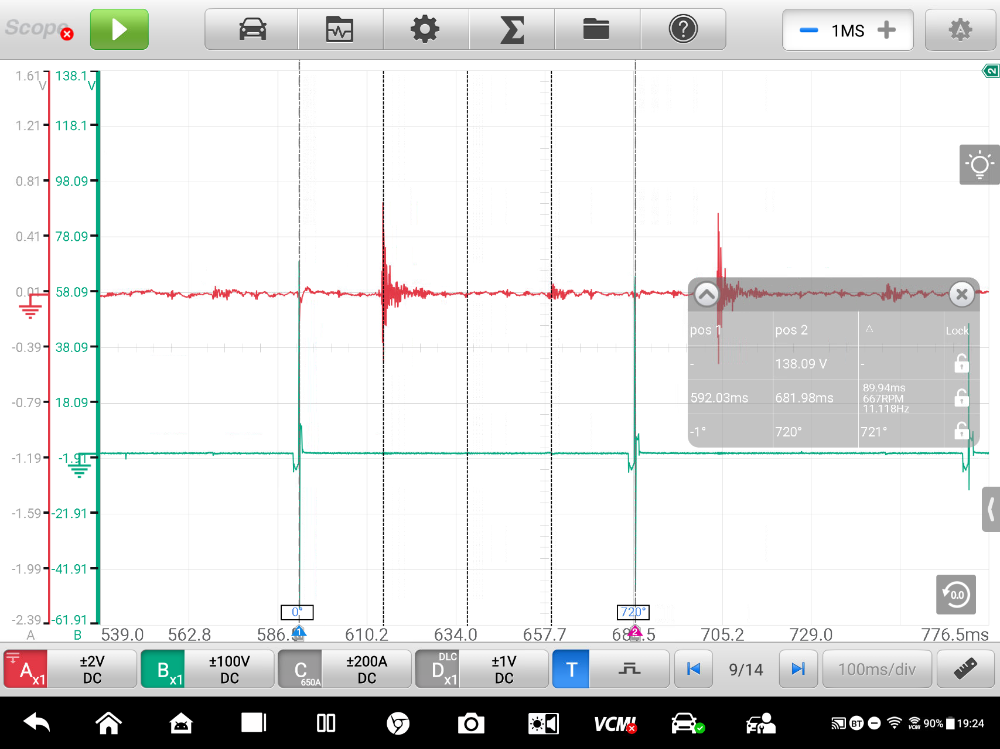

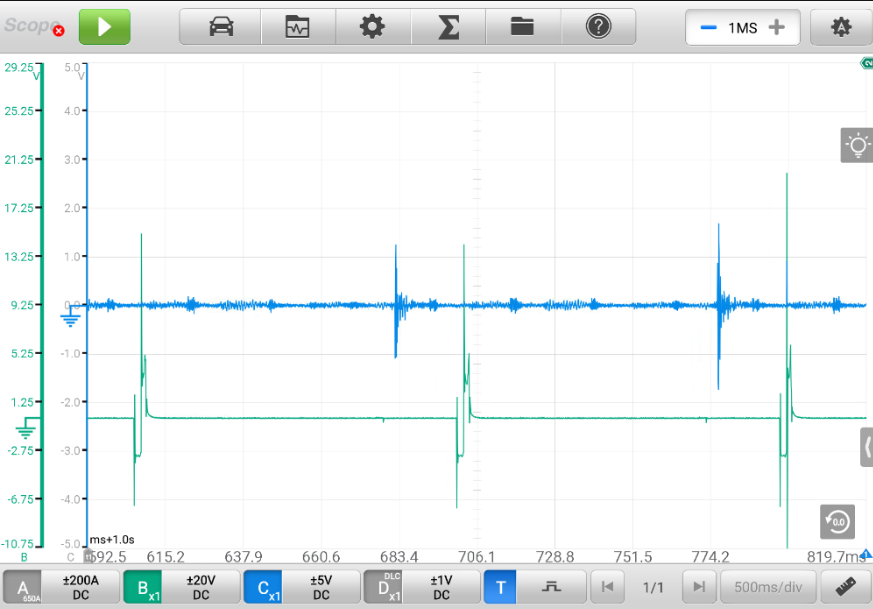

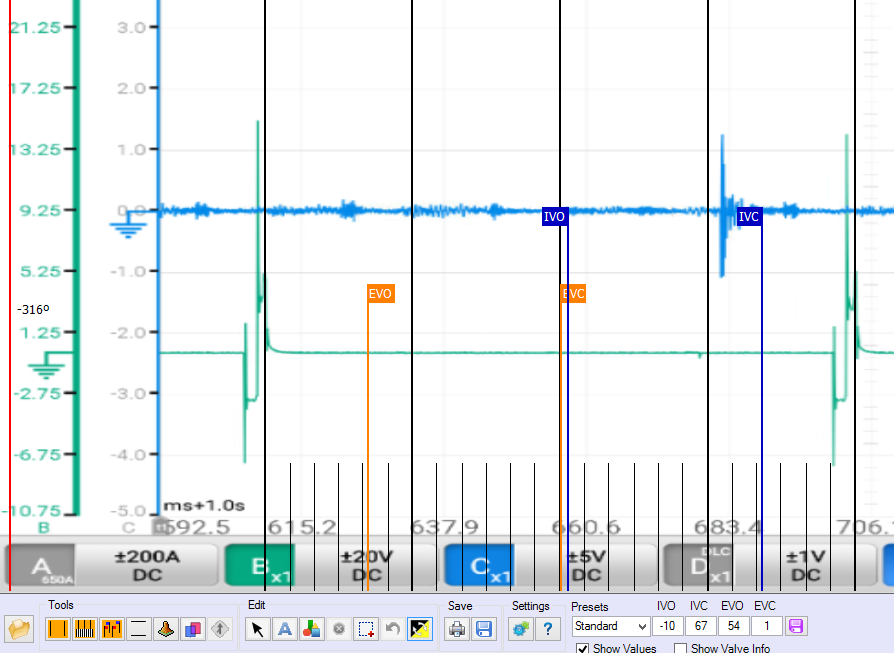

Just off idle, the waveform looks like this:

#1 sync in green, knock sensor in blue. The knock does not change while killing cylinders. At idle, the noise is gone or very intermittent. Zoomed in a bit more:

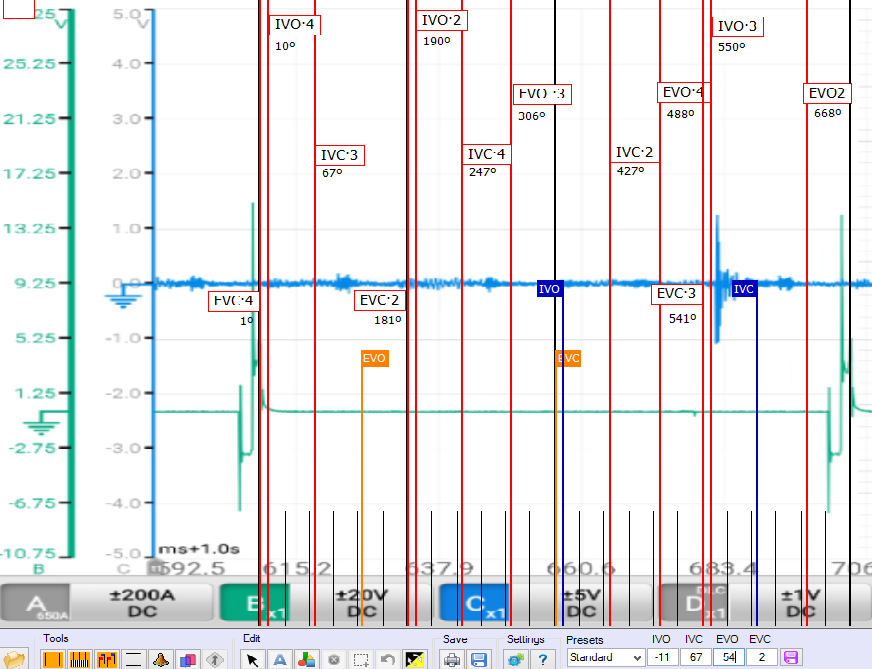

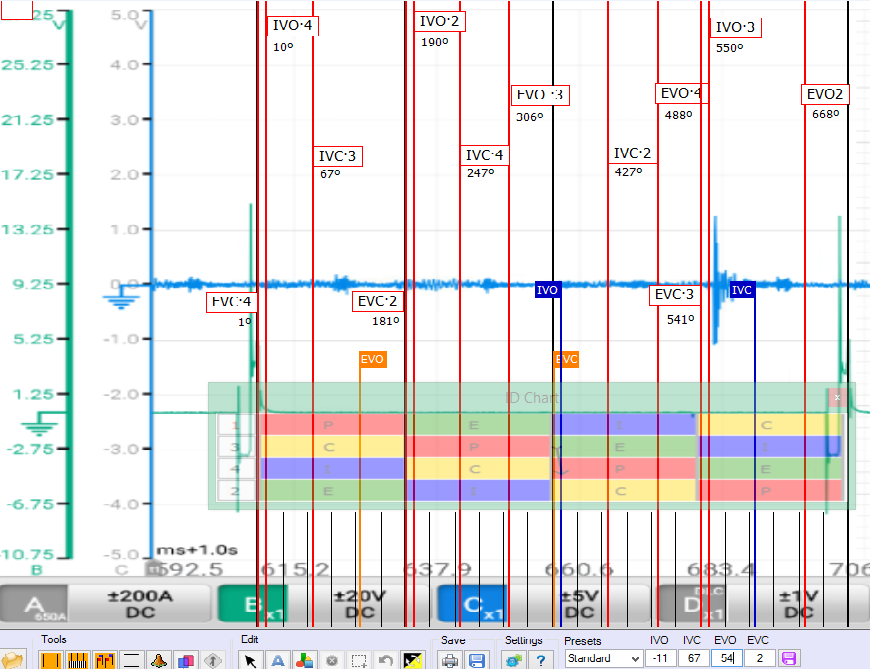

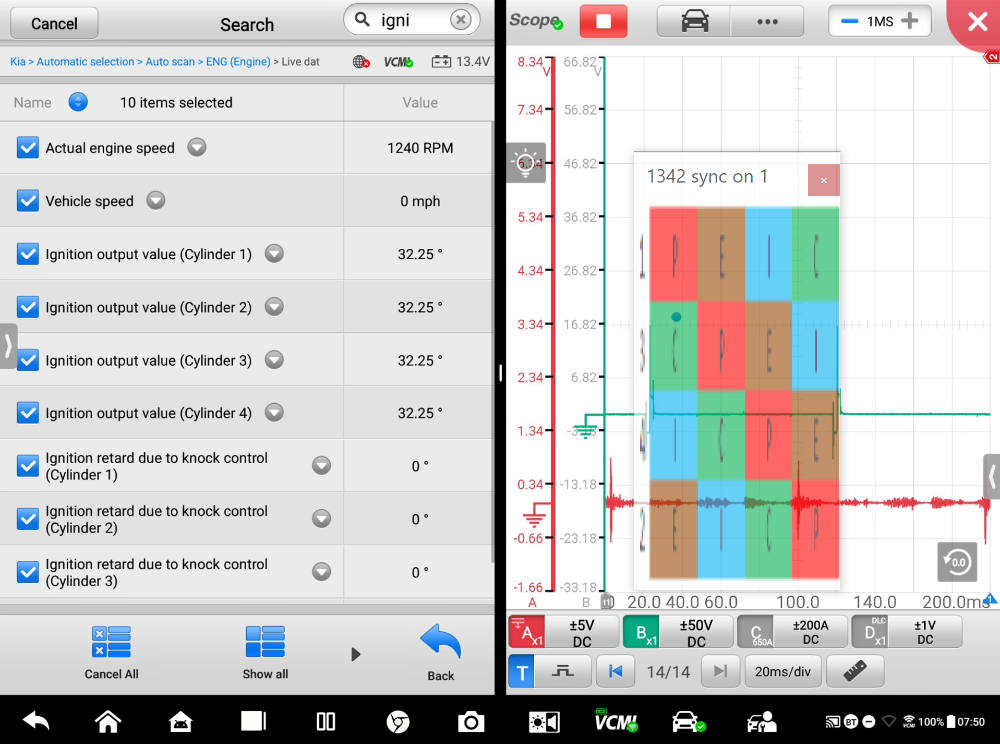

Now for our trusty overlay to put this all in context:

Normally, when I see rod bearing or lower end problems, the knock is directly on one of the TDC lines, right in time with one piston or another at the top of its travel. Check out this thread for an example:

www.scannerdanner.com/forum/post-your-re...s.html?start=0#48537

So if it's not lower end, that leaves us with top end? :huh: If it's a valve event, can we tell which one based on this waveform alone?

The way I see it, there's only a few possible valve events taking place. Intake valve closing on #1. Exhaust valve closing and intake valve opening on #3. Exhaust valve opening on #4.

Am I thinking of this wrong? Not even in the right ballpark? Let me know!

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

Spark will be advanced BTDC. Maybe 27* of advance??

I thought about that? But 27 degrees of advance seems like a lot at idle.

If it is valvetrain you could go old school and pinpoint that with a prydriver :silly:

Sure, but that wouldn't be nearly as much fun to share!

Plus, this engine is getting torn down at the request of an extended warranty company. So we'll (hopefully) get to see exactly where the problem is.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

I thought about that? But 27 degrees of advance seems like a lot at idle.

Yeah I thought it might be too much. But ~1,300 rpm is a good bit off idle.

Regards valvetrain if the engine has VVT you could actuate the phasers to see if the noise moves.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Piston Rod knock will show up at TDC of the Exhaust, this is when the piston has no loads on it.

So by the looks of your captures, #3 would be suspect.

Here is a cool Powerpoint Presentation;

drive.google.com/file/d/1zbuwAAMrDgyNi64...Yge/view?usp=sharing

Cheers

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

Tyler, tap into the engine's Knock signal, maybe AC couple it if need be, and compare it to your sensor.

I may try that! What I like about having my own is not having to dig out the ECM/PCM or find a wiring diagram to get the signal.

Piston Rod knock will show up at TDC of the Exhaust, this is when the piston has no loads on it.

So by the looks of your captures, #3 would be suspect.

I agree 100% that rod knock should show up during the exhaust stroke of a given cylinder. However, I believe this knock is too far after the #3 TDC-E to be a rod. Plus, cancelling cylinders does NOT double the frequency of the knock like it should if it were a rod bearing.

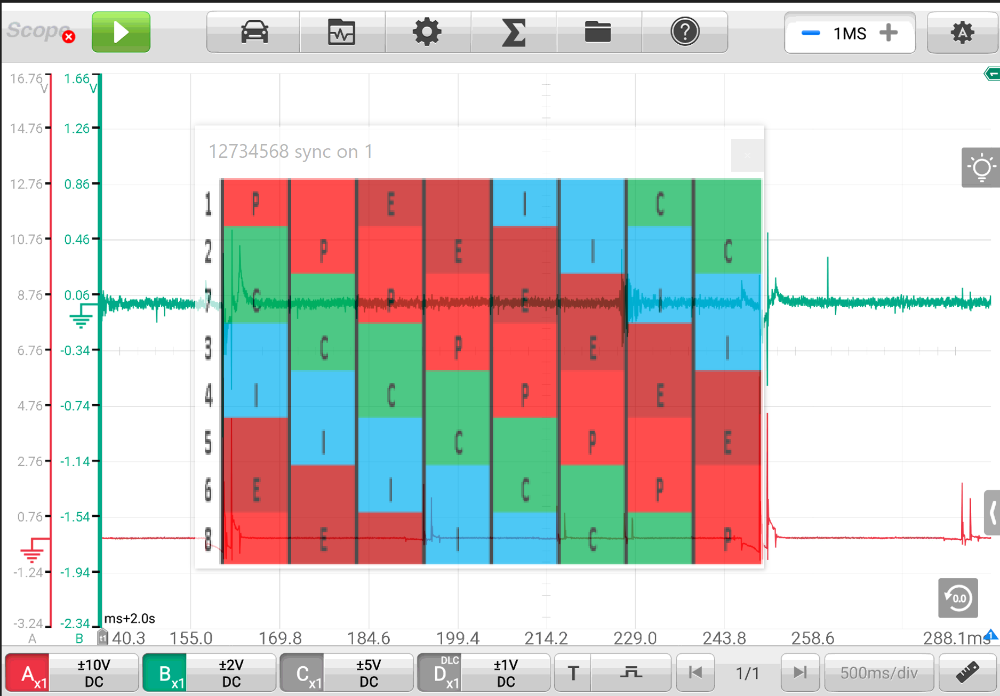

For example, this is a Jaguar 5.0L with a spun #3 rod bearing:

Here's another from a '99 Corolla 1.8L:

In both examples, the knock is very close to or right at TDC. IMO, the Kia knock is too late to be a #3 rod, and too early to be any other rod. But hey, we'll find out.

Here is a cool Powerpoint Presentation;

drive.google.com/file/d/1zbuwAAMrDgyNi64...Yge/view?usp=sharing

Cheers

That's an AWESOME Powerpoint. :woohoo:

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

Here is a cool Powerpoint Presentation;

drive.google.com/file/d/1zbuwAAMrDgyNi64...Yge/view?usp=sharing

Cheers[/quote]

Thank you for the powerpoint. It gives the impression (newer) Subarus are quite prone to bottom end problems.....or is it just coincidence/lack of maintenance/high car count at the dealership?

Is it allowed to share this presentation?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1114

Excellent presentation.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4967

- Thank you received: 1114

I'm not having the greatest success with the Verus and some knock sensors I harvested from a 2.7l Ecoboost F150 engine.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

I thought about that? But 27 degrees of advance seems like a lot at idle.

Yeah I thought it might be too much. But ~1,300 rpm is a good bit off idle.

Checked my 'yota this morning and it went from 9* of advance at idle to 22* at 1,300 rpm. Moved more than I thought it would. If the Kia hasn't been torn down yet might be worth hooking up a scan tool to see how much advance it's running.

Also one interesting thing about the powerpoint captures is there is quite a lot of variation in the timing between ignition sync and noise. First one looks to be happening just before ignition. A couple others are a good bit after ignition similar to this Kia.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

I don't want to detail the discussion here, but are you just using 5v DC scale on the knock sensor channel?

I'm not having the greatest success with the Verus and some knock sensors I harvested from a 2.7l Ecoboost F150 engine.

As knock sensors generate AC signals you also may want to couple the signal that way, just in case there's bias voltage present.

Without bias voltage the visual representation won't change.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

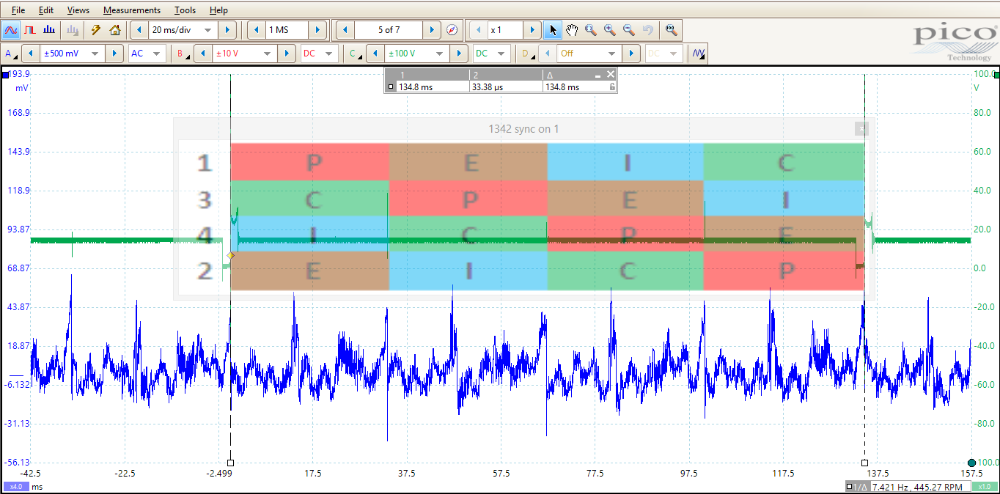

The blue trace is the Knock Signal.

In the first diagram, there is an Rpm of 445 measured between cursors for the #1 ignition strike. So the engine RPM is 445 times 2 = 890 rpm

The cursors are measuring 720 degrees of rotation, we want 360 degrees to get an engine Rpm.

890 rpm divided by 60 seconds gives us ~15 hz. Accuracy here isn't crucial. What is going to be important is the repetitiveness of the signals.

Now we can say at this moment the E1 (first-order) engine frequency is 15 hz.

For example, if there was a repetitive amplitude in the second diagram occurring at the same frequency as the ignition strike, we would call it a first-order (E1) engine vibration event.

A second-order vibration (E2) event at this engine rpm would occur 15 hz times 2 = 30hz., an E3 event would be 15 times 3 = 45hz.

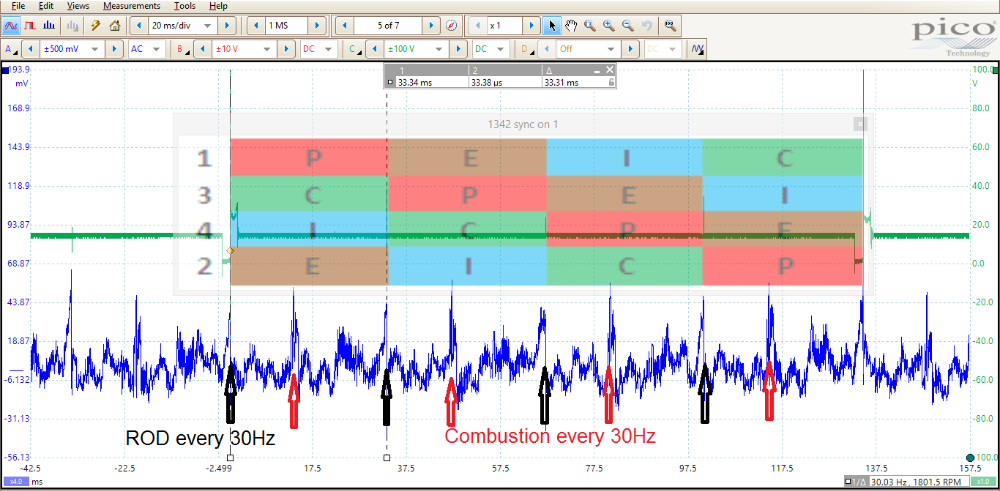

In diagram 2, we can see there are repetitive events on the blue trace. I've labeled them.

These events occur every 30 hz, which in this case is a second-order (E2) engine vibration.

A four-cylinder motor has 2 combustion events every crank rotation, this is considered a second-order vibration. Remember the first-order event was 15 Hz.

It is noteworthy that a 6-cylinder engine has 3 combustion events, they will be E3 (third-order) vibrations. An 8-cylinder has 4 events; therefore E4

So, if we had an 8-cylinder motor running at 2000 rpm (2000/60=~33hz), we would expect to see combustion events every 33hz times 4 =133hz

In the blue trace on diagram 2, we can see the combustion events occurring at 30hz intervals, they center themselves on the piston overlay during the cylinder's combustion stroke.

The other event which lines up directly with all the TDC's Exhaust is the knock event, which is also a Second-Order (E2) vibration.

Knowing this makes it easier to accurately identify an event on this Knock signal trace using Piezo-style "noise" listeners!!!

Otherwise, an accelerometer would be required to obtain actual frequencies instead of having to use the scopes software and a little math to figure events out!

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

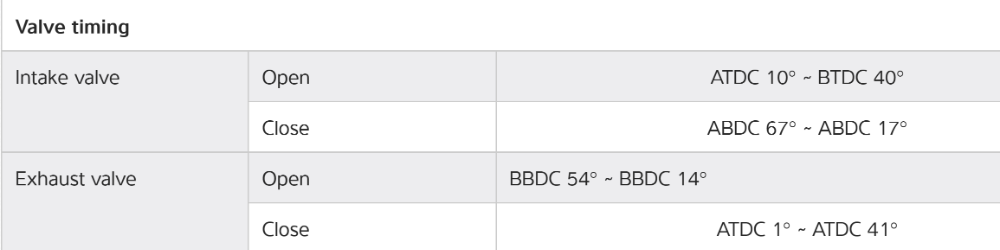

Would you have the cam card/specs available? The CWF programm will allow to overlay the exact valve timing events and we could see if/what may be related to the noise within the top end.

That's slick.

I don't want to detail the discussion here, but are you just using 5v DC scale on the knock sensor channel?

I'm not having the greatest success with the Verus and some knock sensors I harvested from a 2.7l Ecoboost F150 engine.

Yep, regular old voltage trace. No coupling or nothing. I've experimented with AC coupling this probe, but never found that it made all that much difference to the output. I've got both both sensor wires going to the scope - no external ground - if that helps.

Checked my 'yota this morning and it went from 9* of advance at idle to 22* at 1,300 rpm. Moved more than I thought it would. If the Kia hasn't been torn down yet might be worth hooking up a scan tool to see how much advance it's running.

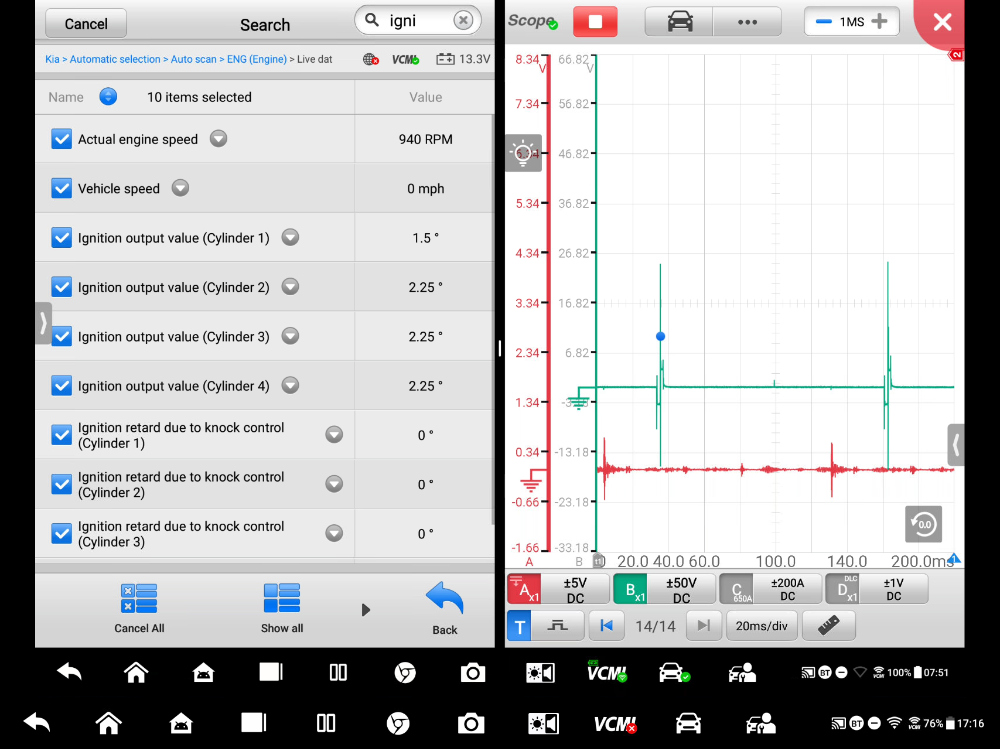

That's interesting. :huh: It has not been torn down yet. I'll see if I can get a side-by-side screenshot of the scan data and the knock sensor scope trace.

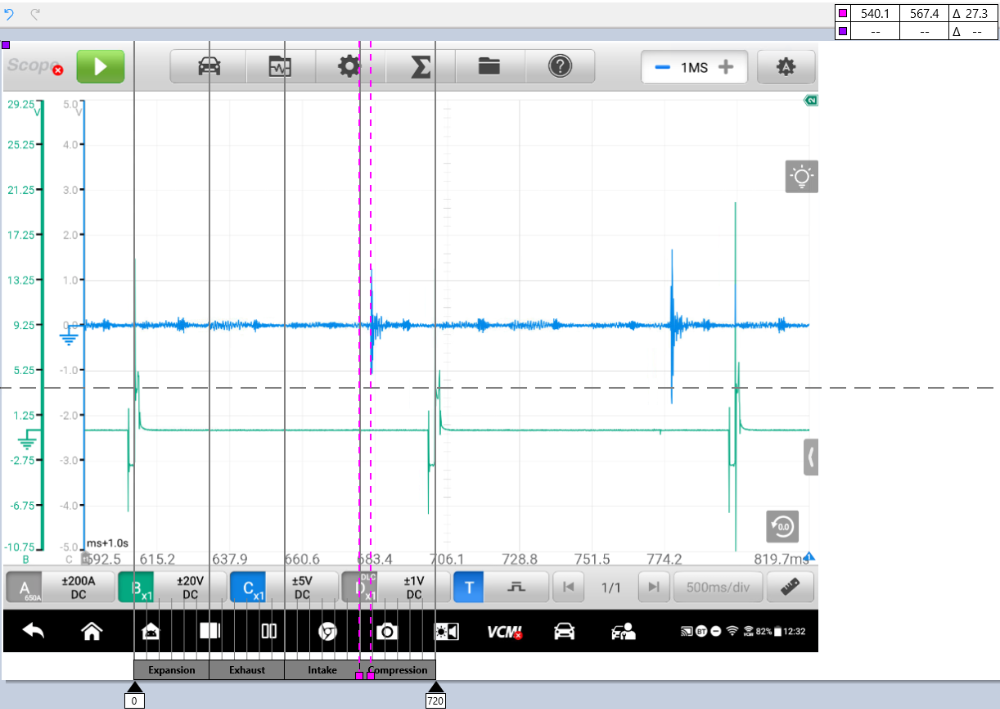

Of course, when it rains, it pours. :silly: Had another knocker come in today, a '11 Chrysler 200 2.4L. Sync on #1:

The shot below was taken at 1300-ish RPM (the Autel rulers don't calculate four stroke RPM correctly). If the 200 advances timing off idle, it's not much.

I called a #2 rod bearing. Many thanks to everyone that's replied.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

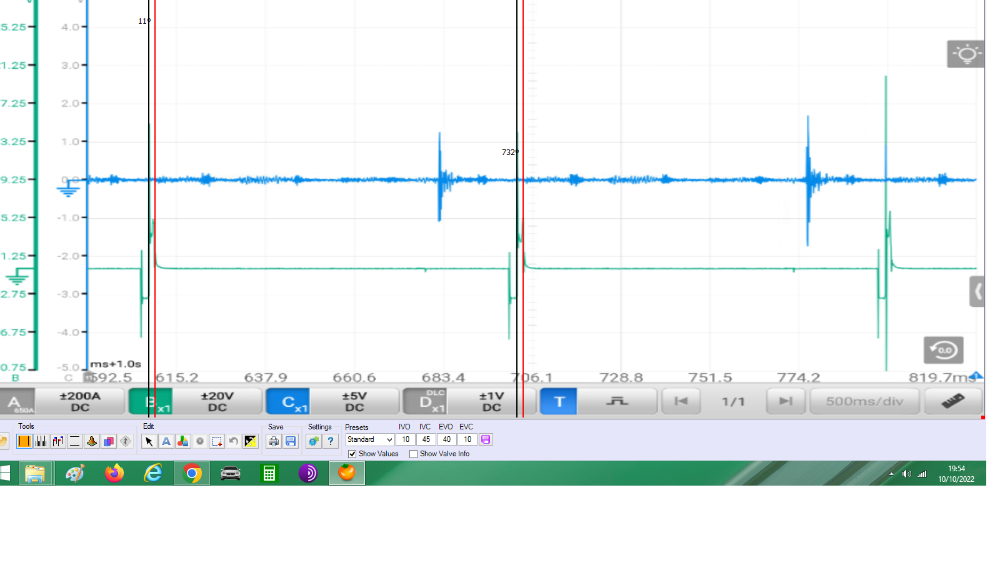

I made some assumptions:

1- idling I`d give it 10 degrees BTDc as base ignition timing (being slightly off idle it would be even more which may fit even better do correlate the knock

to one specific event in the valve train)

2- at this low speed both VVT sprockets are in the locked position: the intake valve events would take place at the most retarded position within the possibl degree range and the exhaust valve events happen at the earliest possible degree/point in time.

Based on the original capture I calculated number 1 TDC compression, applied the 720 degree markers and then marked the valve events for all 4 cylinders. Though the resulting pictures are pretty clouded they suggest the knock is related to the number 3 intake valve opening.

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

do you have any news on this one?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

Tyler,

do you have any news on this one?

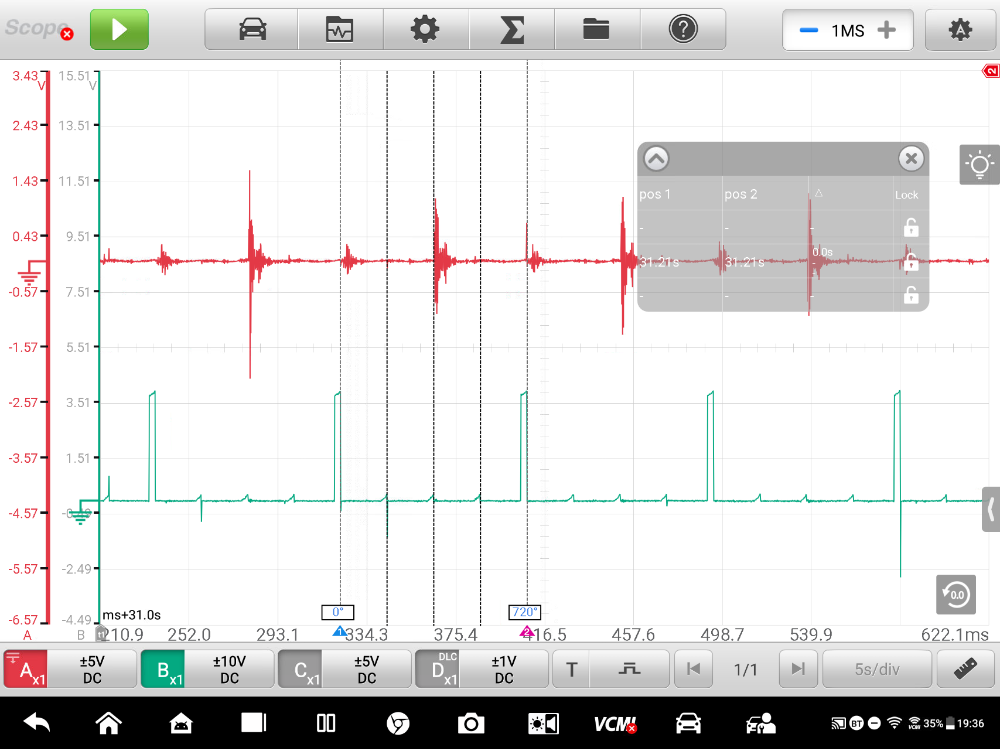

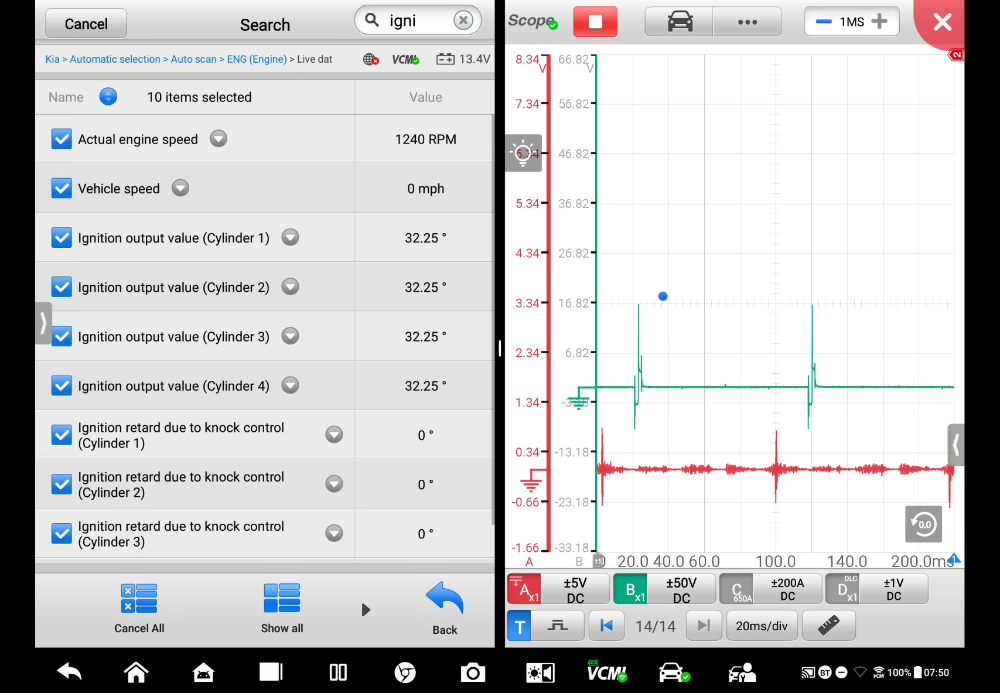

Yep! Got back to this one and took some more captures. Cliffnotes version: Matt T was right to ask about spark advance. :blush:

I got the Autel rigged up to watch the scan data and the scope. This is a shot at 900-ish RPM. The knock comes and goes at idle, but I happened to catch it at the right time:

A few degrees of advance, nothing unusual. Same shot with an overlay for reference:

Right in line with #3 TDC-E.

32 degrees. :huh: I saw 42 degrees @ 1500 RPM at one point. WAY more advance than I ever thought there would be.

Same shot overlayed:

And there's the late (appearing) noise, just like in my first post.

So, again, Matt T called it a mile away.

Sorry to send everyone on a wild goose chase. :blush: But I genuinely appreciate all the responses.

Please Log in or Create an account to join the conversation.

- Tyler

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6080

- Thank you received: 1537

drive.google.com/file/d/1L8pKhkuquZDDoE8...sF1/view?usp=sharing

Now, a question to the working wrench-turners and hammer-swingers around here. How is this getting fixed in your shop? Short block, used engine? Roll a bearing in it and send 'er?

Please Log in or Create an account to join the conversation.