96 Honda Accord 5 speed (F22B2 engine), mysterious misfire

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Basic scenario

96 Honda Accord LX 5 speed manual ( F22B2 engine )

Car ran perfect before removing the engine for a rebuild.

It sat apart for 6 months waiting on the machine shop.

I re-assembled it. No leaks, everything looks present, clean and working.

It now has a bad constant misfire at all RPM's, but it is less severe at higher revs.

Short term fuel trims swing from +20% to -20% at different times. Sometimes it stay negative, sometimes it stays positive

Idles very rough and stalls.

Also has foul smelling exhaust ( but not like rotten eggs ).

No check engine light unless I let it almost stall and try to keep it alive with the throttle.

Then the check engine light comes on and I get 5 codes:

P0301 Misfire Cylinder 1

P0302 Misfire Cylinder 2

P0303 Misfire Cylinder 3

P0304 Misfire Cylinder 4

P1300 Multiple Cylinder misfire

I threw 4 new injectors at it ( mistake, it made no difference )

I threw 4 new NGK spark plugs at it last night, properly gaped to 1.1mm ( made no difference ).

I cleaned the connections on the ICM ( made no difference )

I clean all of the connections on the cap, rotor, button and wires ( made no difference ).

I diligently tested all of the secondary components for spark leaks, I can't find any.

I tested the secondary for spark strength from the 4 outputs of the rotor cap. Thin blue sparks 3/4" long on all of them.

The distributor has a tiny oil leak on the inside, but I don't think that is causing a problem. I've cleaned it out many times, makes no difference.

I've also done lots and lots of other checks and tests probably not listed. I have no idea what is wrong, but I don't want to just throw parts at it to fix it.

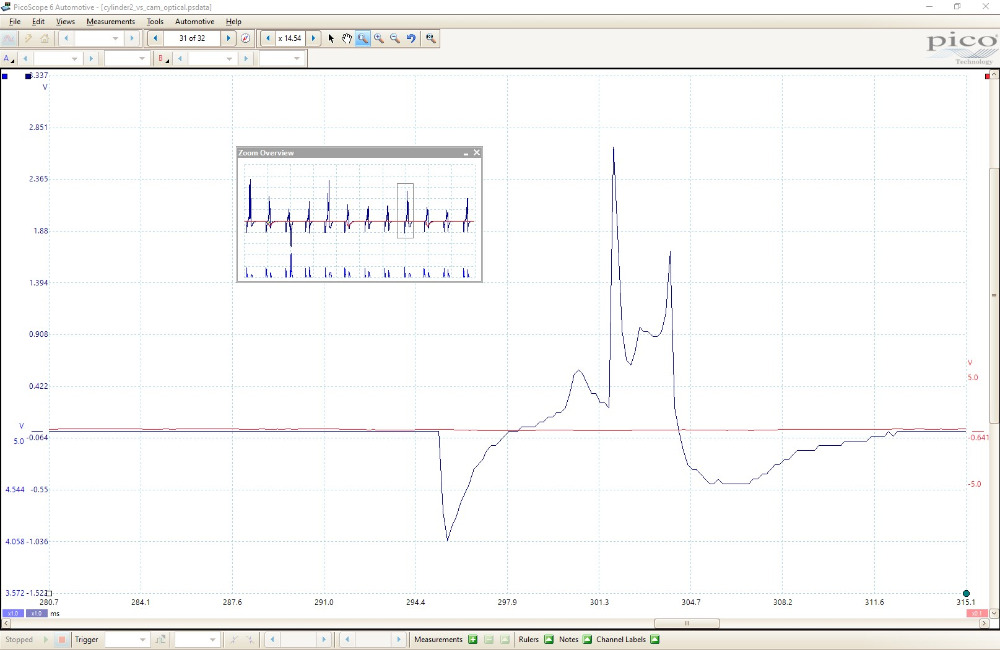

I got a 2 channel picoscope and created an optical sensor to read the cam rotation in real time so that I could have at least 1 sensor that I could trust given all of the unknowns. I'm hoping someone can help me figure out what is wrong with this car. Feel free to request test data, video... whatever you want to see. I'm currently stumped. The secondary spark signals are completely insane on all cylinders. I have no idea why.

It looks like the forum will only let me post 8 files, so I choose what I think are the most important ones. I have a lot more data + pictures. Maybe I'll be able to post more in future replies?

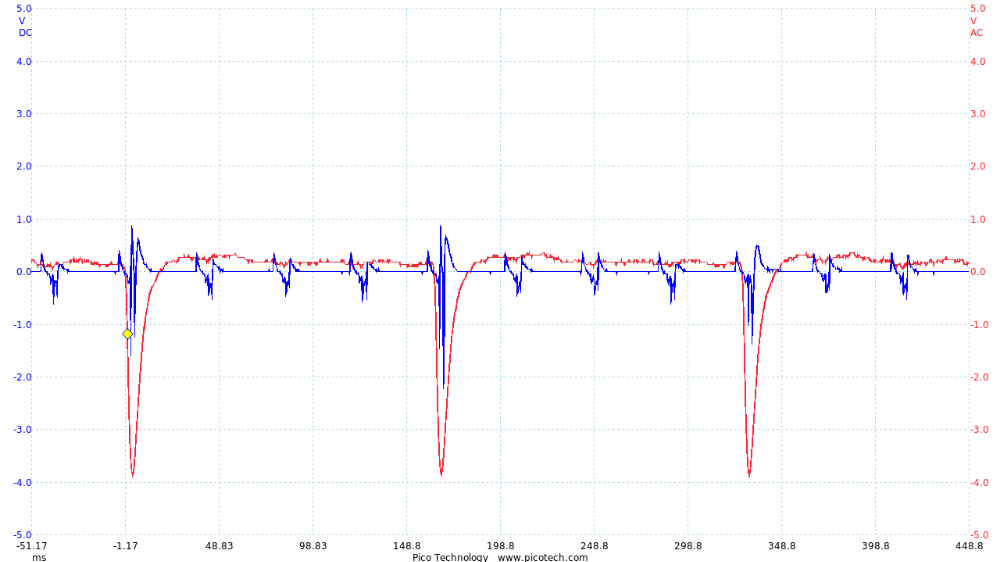

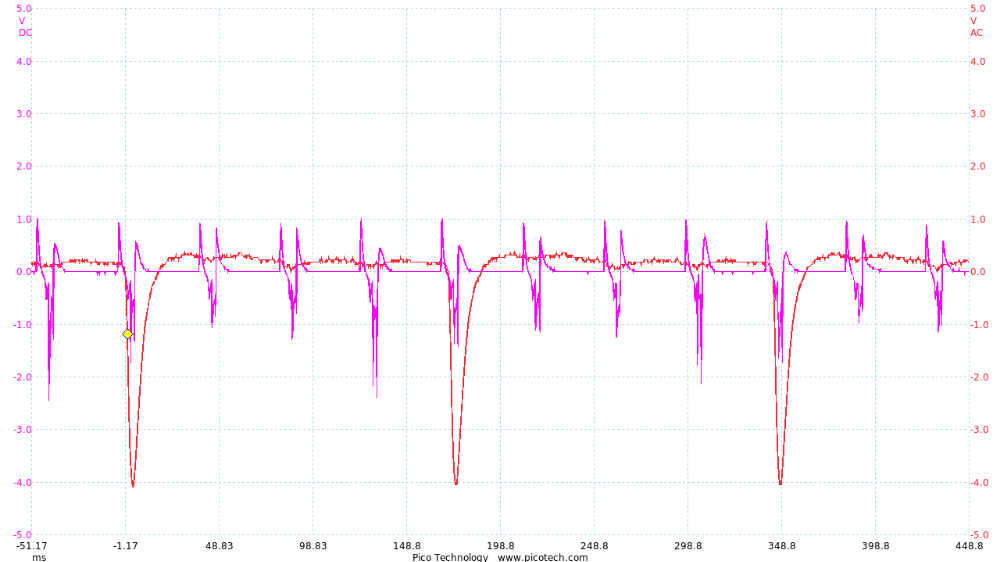

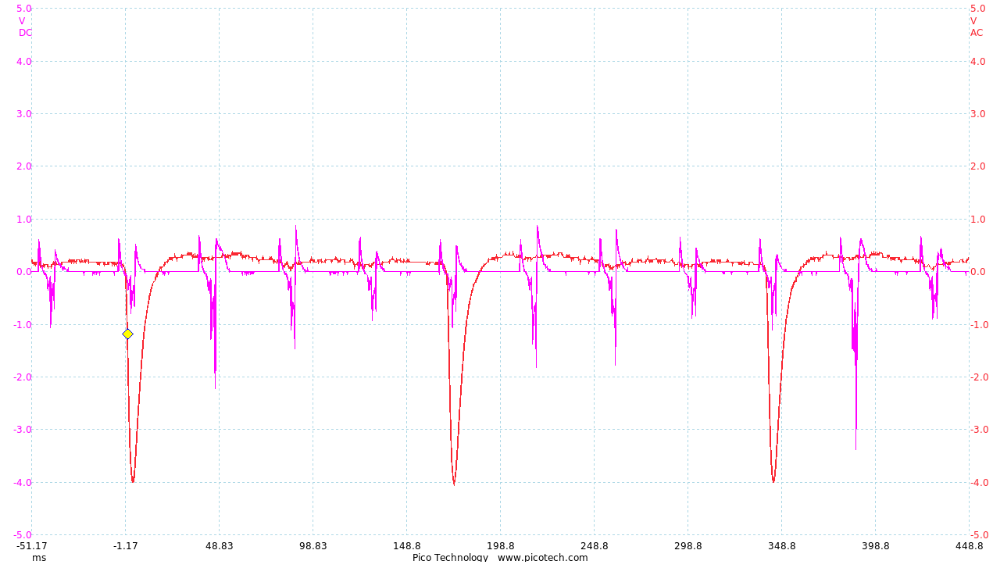

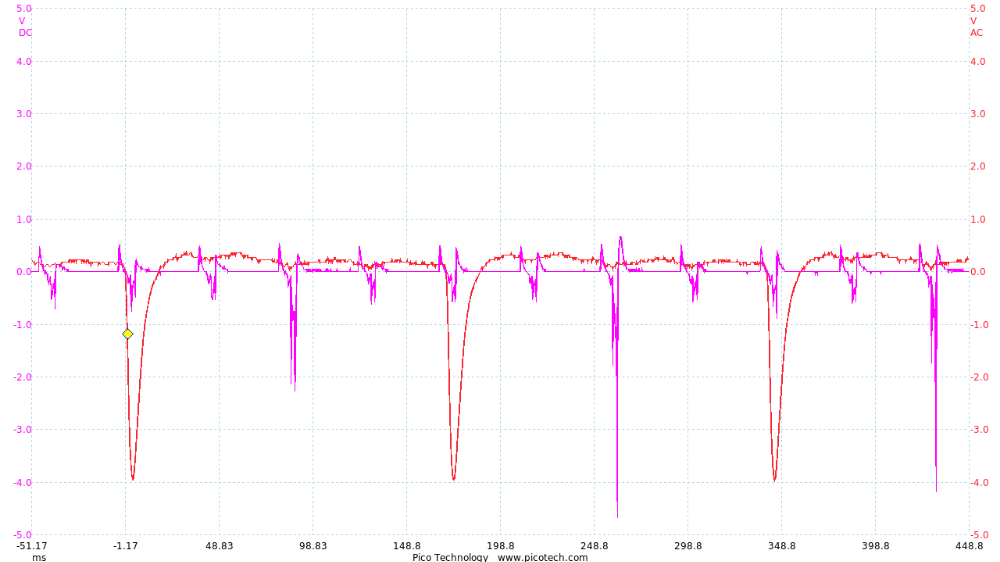

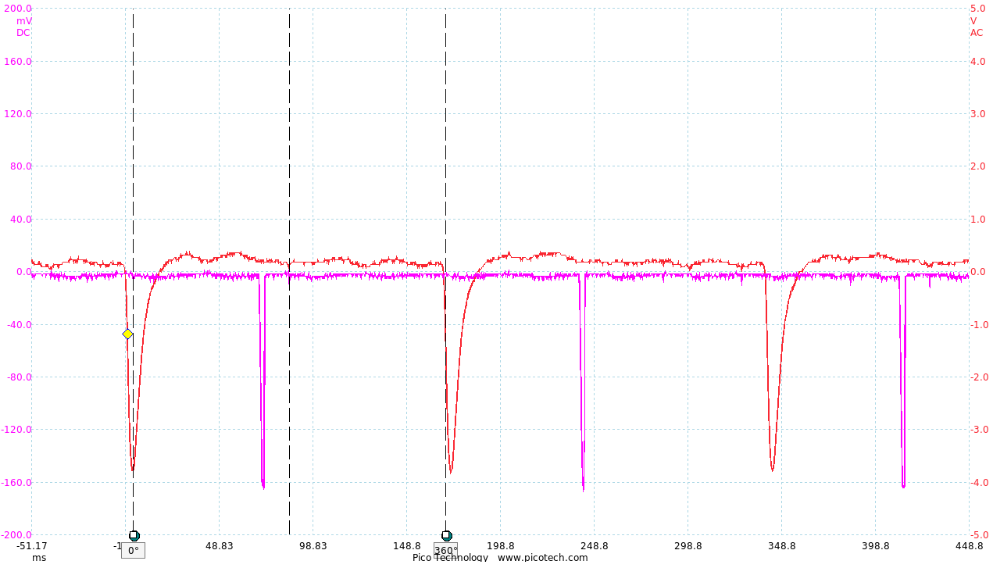

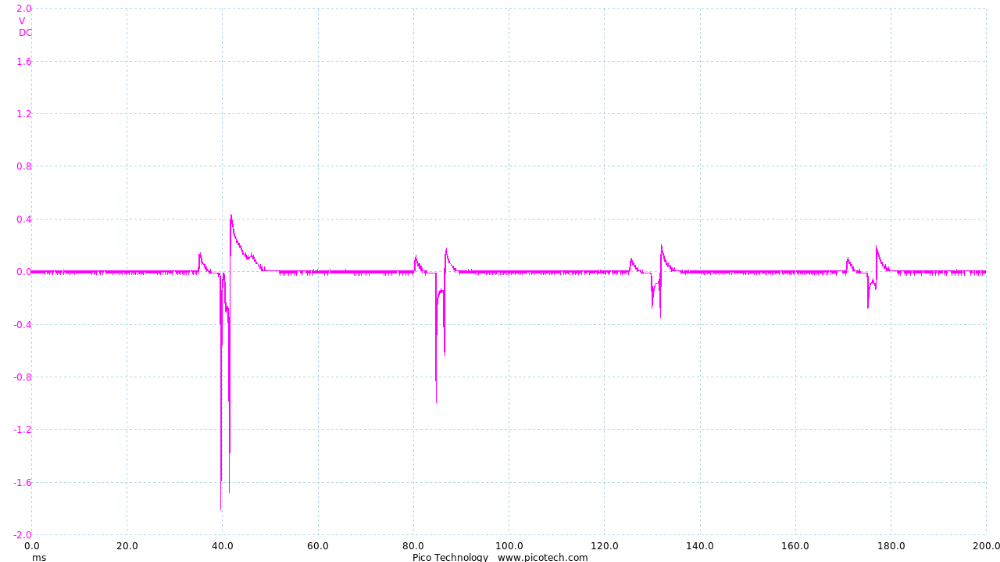

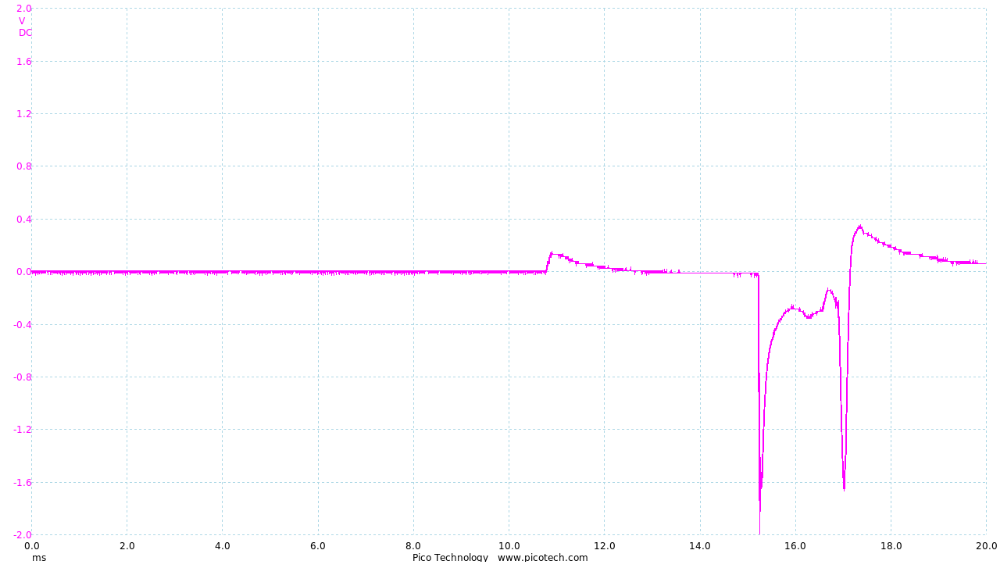

As you can see in these wave forms, the secondary ignition is ALL over the place on all cylinders

Cylinder 1 vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

Cylinder 2 vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

Cylinder 3 vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

Cylinder 4 vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

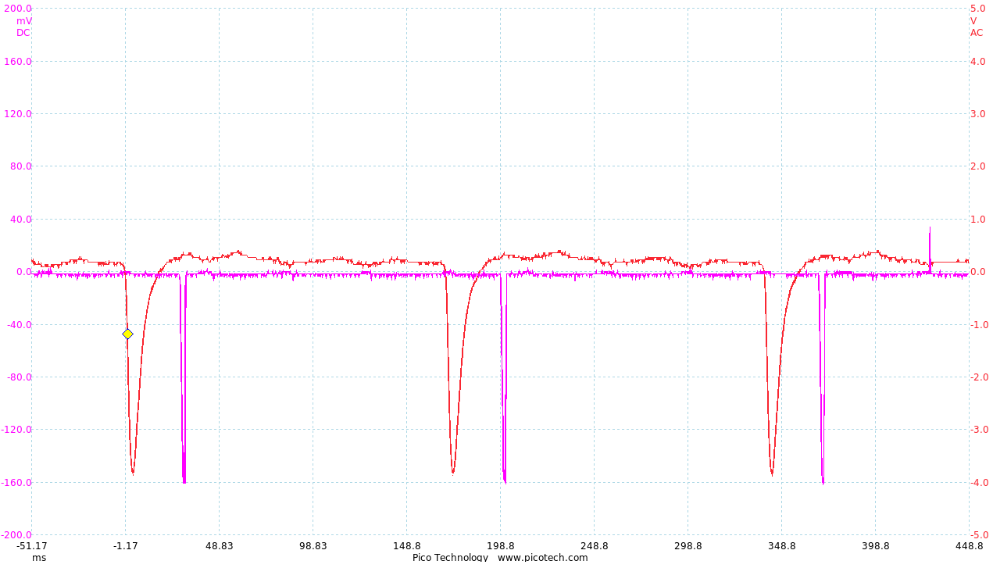

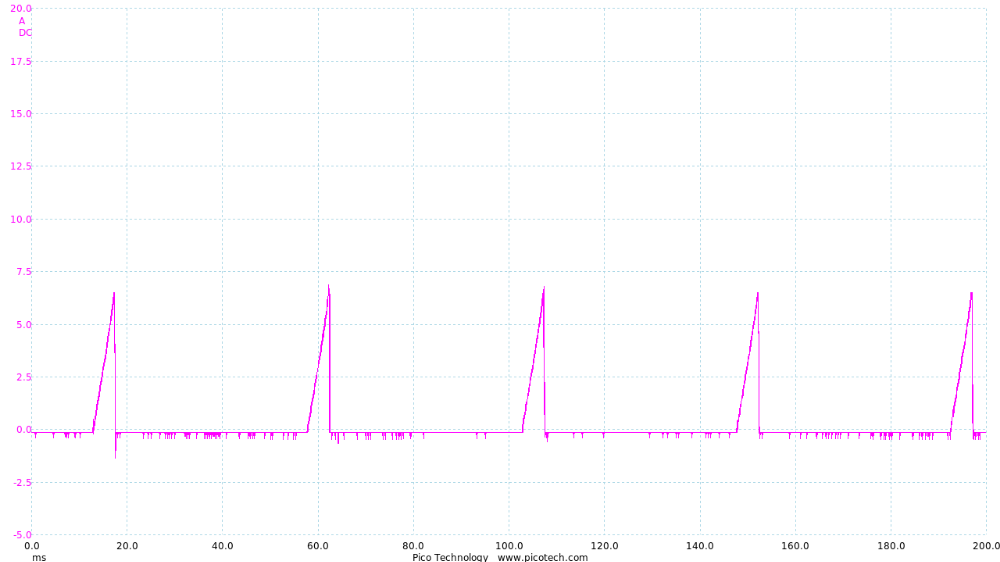

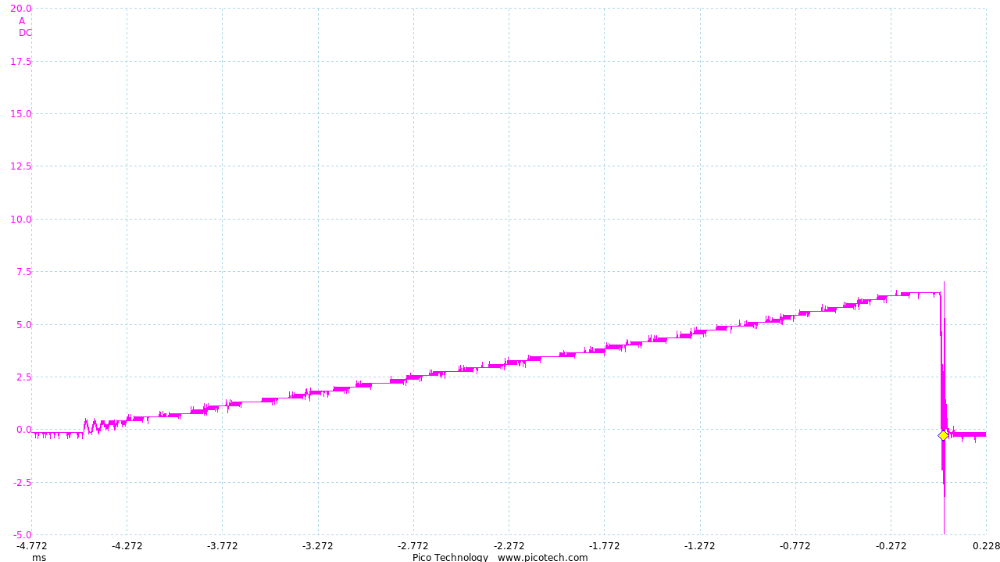

The purpose of these injector current rams was mainly to show their timing. If you want a close up of the current ramp, I can provide that too.

Note: The injector current was measured using a DC amp clamp on the 1mv/10mA setting

#1 Injector Current vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

#2 Injector Current vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

#3 Injector Current vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

#4 Injector Current vs cam optical sensor ( the signal bottoms out at Cylinder #1 TDC compression stroke )

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Cylinder 1 Spark(Blue) vs Cam optical(Red)

Cylinder 2 Spark(Purple) vs Cam optical(Red)

Cylinder 3 Spark(Purple) vs Cam optical(Red)

Cylinder 4 Spark(Purple) vs Cam optical(Red)

Note the injector current was measured using a DC amp clamp on the 1mv/10mA setting

Injector 1 Current(Purple) vs Cam optical(Red)

Injector 2 Current(Purple) vs Cam optical(Red)

Injector 3 Current(Purple) vs Cam optical(Red)

Injector 4 Current(Purple) vs Cam optical(Red)

Note: the interference on this one is caused by the HV coil. Cylinder 4 is right next to it.

Please Log in or Create an account to join the conversation.

- Desmond6004

-

- Offline

- Platinum Member

-

Getting involved in discussions because I have a lot to learn still.

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Right now I'm basically just waiting for the rain to stop. It has been either pouring rain for freezing cold outside where I live for MONTHS! I'm talking like 3 straight months of rain! I'm no stranger to working in terrible conditions... but the expensive diagnostic equipment can't take it.

So when the weather allows I'll do some more diagnostics and check the exhaust back pressure at the EGR valve. Sadly I don't have much hope of finding a clogged exhaust because it currently shows none of the symptoms.

Intake vacuum is not low. Comparing my MAP sensor readings to my 99 civic both during idle are identical. The engine does not lack power at higher rpms under load. In fact it runs better in that condition.

yeah... I'm stumped. this is the first time I've ever seen anything like this.

What would cause misfiring on all cylinders when:

Spark timing seems correct ( by all the ways that I have measured it )

Spark from the D-cap is thin, blue, snappy and 3/4" long on all cylinders

The primary current ramp looks normal and tops out at 6.5 amps

The HV coil passes the ohm test on both halves

The spark plug wires are only 1 year old, don't leak spark and pass the ohm test

The spark plugs are brand new NGK's properly gaped to 1.1mm

Engine compression is 210psi on all cylinders after 5 puffs

Fuel is fresh 87 octane, which passed the alcohol water test ( there is no water )

Fuel injector pulses atleast look reasonable ( though I'm no expert on that ).

Fuel injector spray pattern is dead even and a fairly fine mist.

Fuel injector pressure drop test is dead even

Fuel pressure is always between 36 and 42psi

The only 2 measurements that I have taken that even show a problem are:

1.The spark measurements above are all over the place

2. Using a spark timing light shows correct timing most of the time, but sometimes just goes wild ( about 1 out of 5 times or so ).

So... how can the spark plugs not be properly sparking, when everything that I'm able to check seems perfect? Clearly something is wrong somewhere...

Here are some ideas that I've come up with that are on the wild side. I doubt that they are true... but since I'm running out of ideas the wild ideas are pretty much the only ideas that I have left.

Maybe since the rebuild 87 octane fuel is no longer high enough octane?

Maybe the air or fuel is getting polluted with something foreign before being burned?

Maybe something in the cylinders was mis-shaped or somehow damaged by the machine shop in a way that affects all cylinders?

Maybe the ECU has lost its marbles and is no longer properly managing the fuel mixture?

Please Log in or Create an account to join the conversation.

- Desmond6004

-

- Offline

- Platinum Member

-

Is the distributor mounted correctly? If the rotor is between outputs when it fires it could be jumping to the next/previous cylinderhakachukai wrote: 2. Using a spark timing light shows correct timing most of the time, but sometimes just goes wild ( about 1 out of 5 times or so ).

now and then.

Getting involved in discussions because I have a lot to learn still.

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

As far as I know the distributor is mounted correctly. My is not adjustable like it is on the civics. It only bolts on in one position. The coupler on the shaft is also offset, so it's not possible to install it backward.

That said... I'll go check it out in detail, take some pics and report what I find.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2109

- Thank you received: 704

hakachukai wrote: As you can see in these wave forms, the secondary ignition is ALL over the place on all cylinders

What kind of secondary probe are you using. It looks like you need to increase your sample rate.

I used a math channel to inverted your secondary wave. I think your sample rate is way to low.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

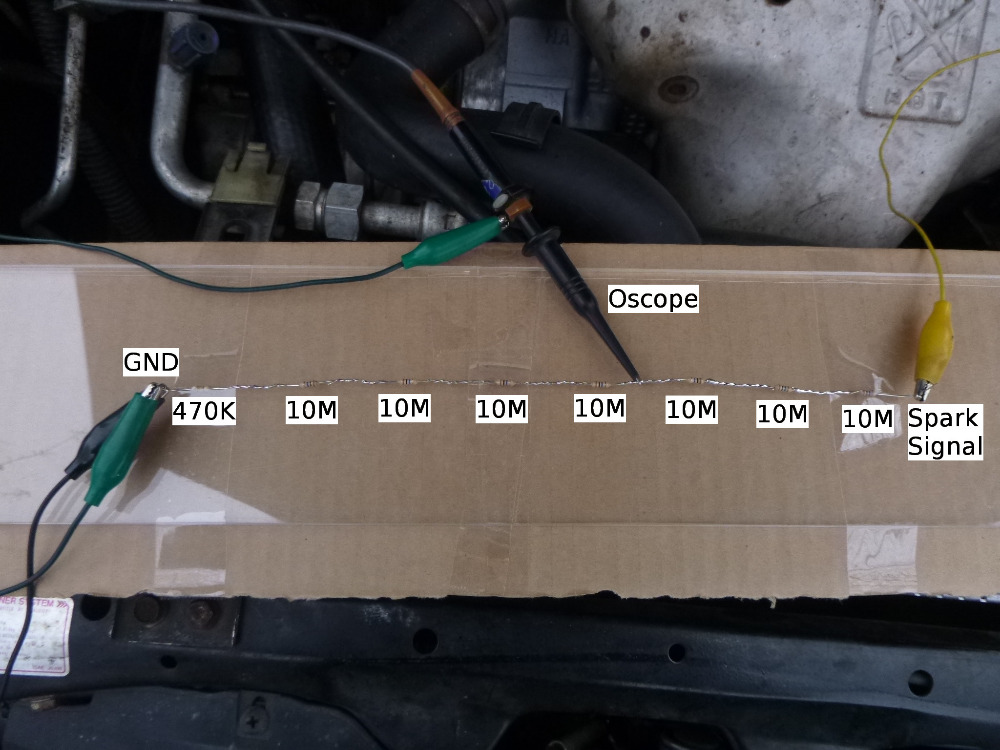

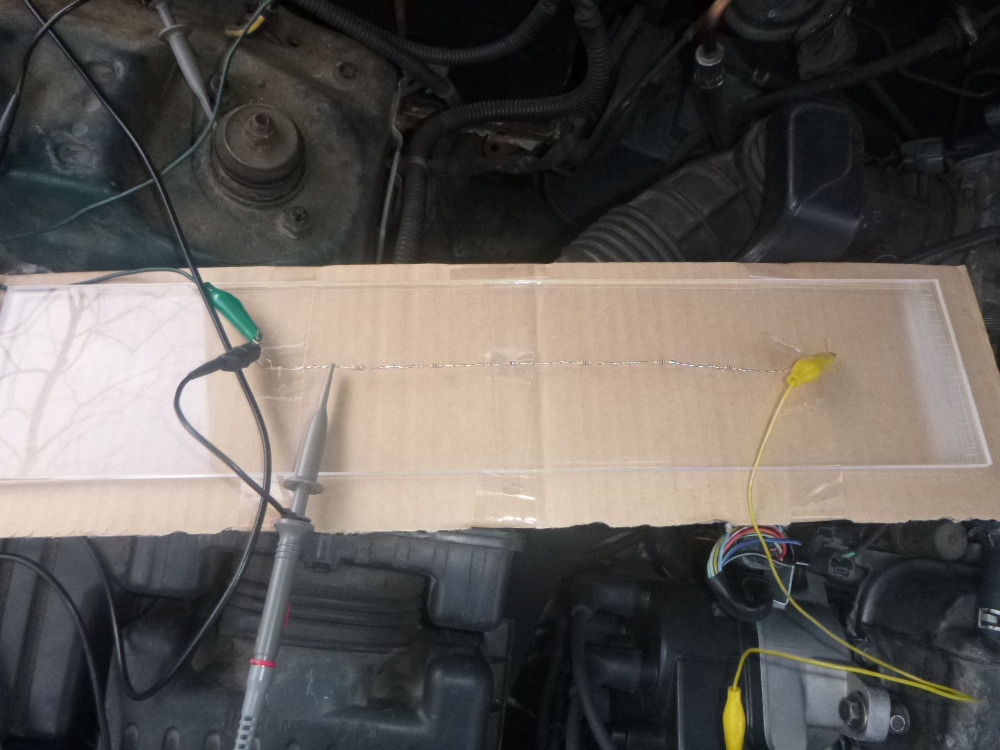

My Secondary probe is basically an insulated steel spring clip that does capacitive coupling to the spark plug wires.

I made a voltage divider / attenuator out of high value resistors. The total resistance is about 72M ohms.

The signal sent to the O-scope is reduced by a factor of about 140.

So the Oscope sees the original voltage picked up by the steel clip/140

Here are some pictures of the DIY probe. After that I'll post known good test results from my 99 civic.

Ignore that Oscope probe. That is not where the scope gets connected

The steel capacative clip. It has a few layers of packing tape on it for extra insulation

The voltage divider with Oscope connection point. That's a voltage reduction of 140:1

The voltage divider with Oscope connection point. That's a voltage reduction of 140:1

The Oscope probe is set to 10:1 attenuation

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Take at Idle, mostly warmed up in 70Deg air temp

Primary Current Ramps

Primary Current Ramps close up

Secondary Ignition Cylinder 1

Secondary Ignition Cylinder 1 close up

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

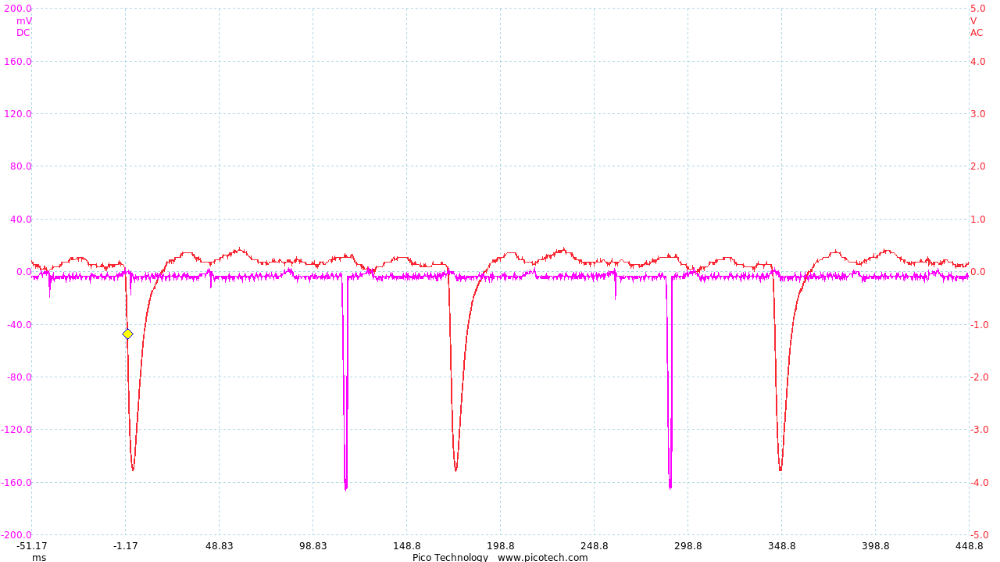

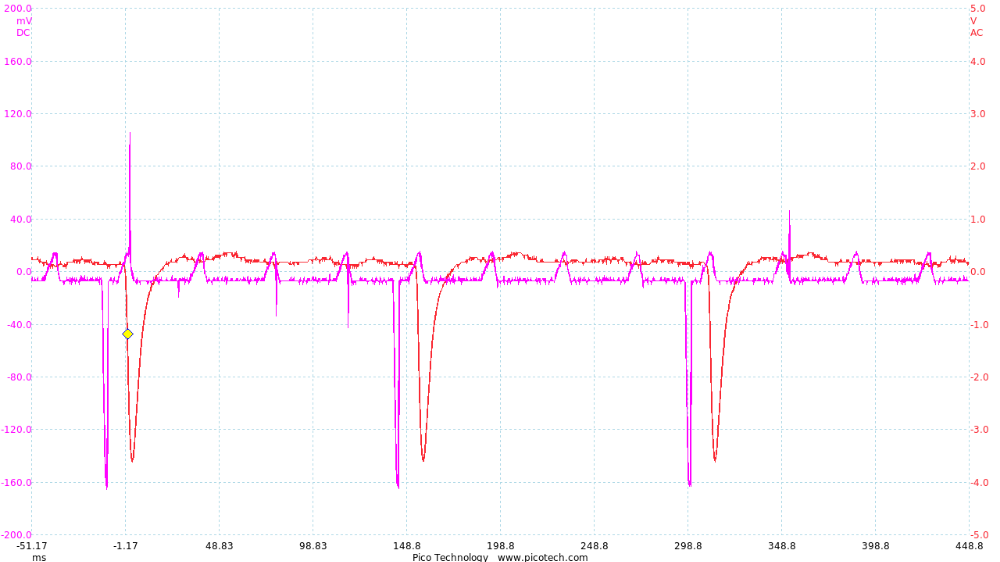

This is at idle doing some snap throttle tests:

As you can see in the data, the secondary wave forms have a large variety in them.

Some are rich, with low spark initiation points and have a burn line that quickly dips down.

Some are super lean, ending with a voltage that is so high that when the spark terminates it sends a huge reverse voltage spike back into the coil.

I'm not sure what is causing this... but it does seem to go along with fuel trims being all over the place.

But which one is the chicken and which one is the egg?

Are the unstable fuel trims causing the erratic misfires?

Or are the erratic misfires sending unburned fuel to the O2 sensor, causing unstable fuel trims?

I did try unplugging the primary O2 sensor and running it that way. It made no difference. That was before I owned my Picoscope, so I haven't measured it like that yet.

Still stumped... I don't know... yet

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

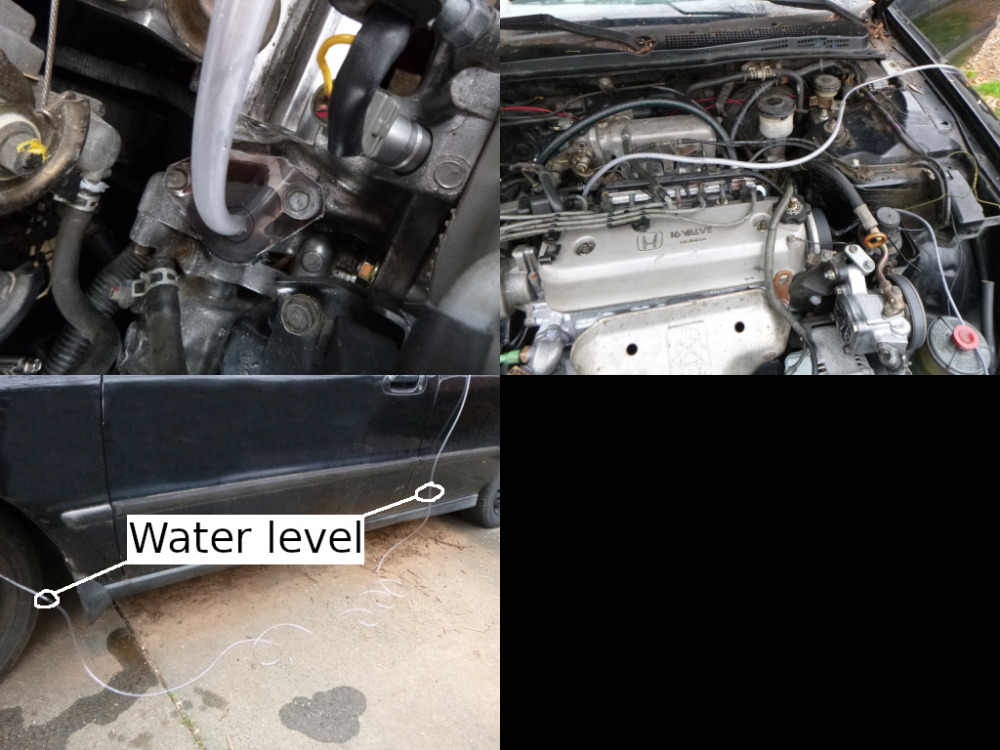

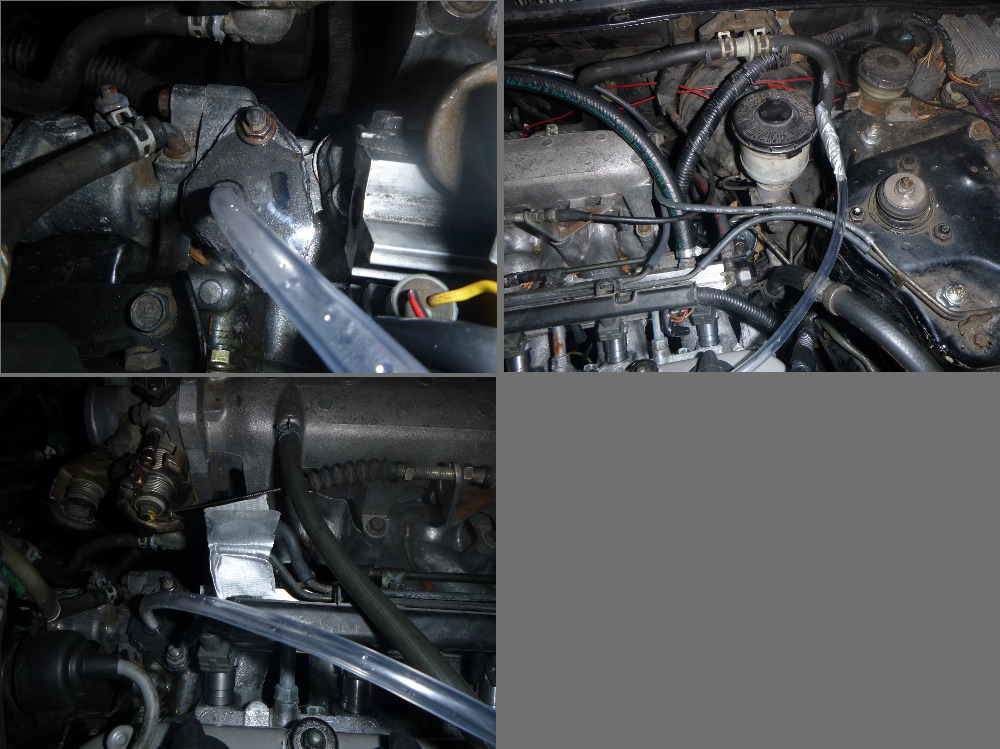

Here is the basic set up. I removed the ERG valve, cut a piece of poly carbonate and sealed it all in place with RTV. As you can see the EGR nuts hold in place. It doesn't leak. I checked multiple times.

The Test results at 3k and 1.2k RPM's. As you can see from the result there is almost zero exhaust back pressure.

This removes exhaust back pressure from the list of possibilities.

I'm not really sure what to check next because I have checked everything imaginable so many times.

Something is wrong somewhere... I'll find it eventually.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4901

- Thank you received: 1092

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

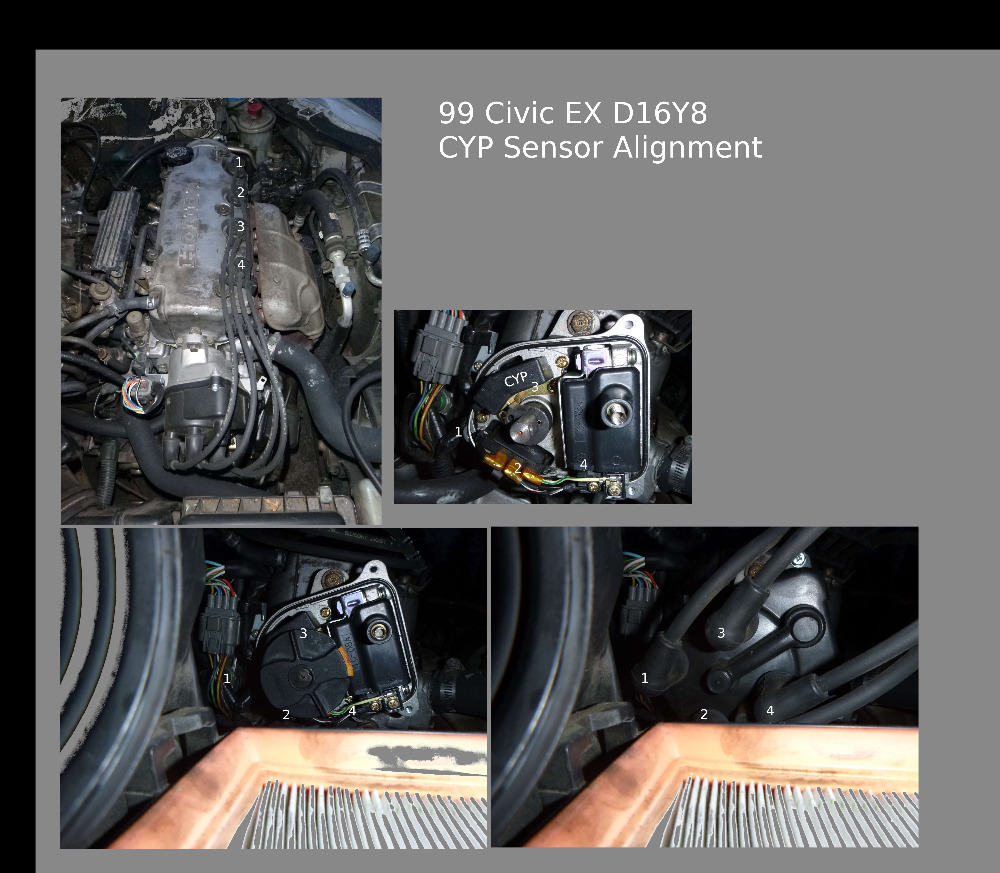

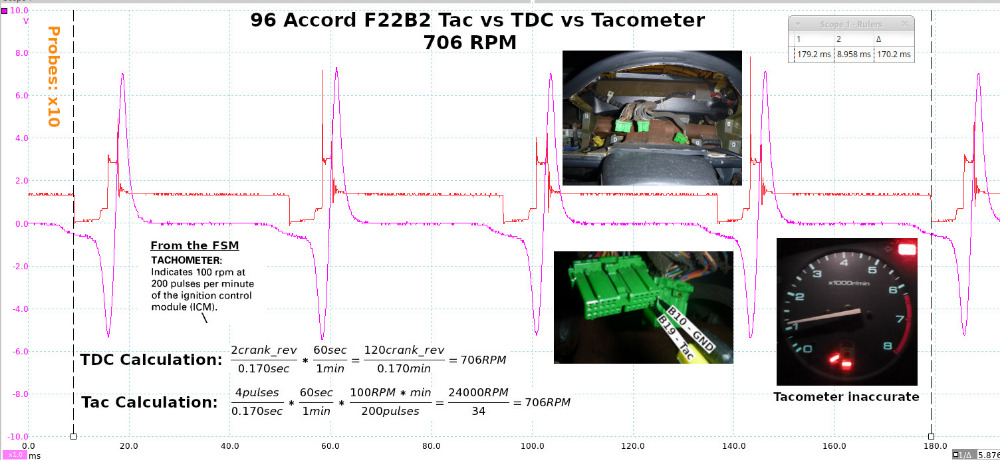

The actual signal seems fine, but I'm wondering about the timing. With my current set up, the CYP signal is triggering between cylinder 3 and 4.

The firing order of this engine ( as far as I can tell ) is: 1 - 3 - 4 - 2

Cylinder 1 is on the driver side of the car ( same as the crank pulley )

Cylinder 4 is the passenger side of the car ( same as the flywheel/clutch )

According the PDF manual that I have, its purpose it to set fuel injection timing by keeping track of cylinder 1. It's not adjustable, so if it's wrong, that would mean that my distributor somehow got 180 deg out of phase. If I flipped the shaft on the distributor ( which would take a good bit of work BTW ) then the CYP signal would trigger between cylinder 1 and 3 ( but I'd also have to flip the rotor button 180 deg... if that's even possible ).

The distributor is not adjustable on this engine. It has regular round bolt holes. It only bolts on in 1 position.

I'm also of course wondering what good fuel injector timing looks like so that I can check that.

EDIT:

===================================================================

So I went and checked out my 99 civic EX's CYP sensor. It lines up exactly like it does on my 96 Accord. Right between cylinder 3 and 4 ( as you can see from the white numbers ).

I have verified that the plug wires are connected in the right order on the 96. The CYP sensor alignment matches my 99 civic exactly. My distributor on the 96 is not adjustable. I think this rules out all issues related to the distributor timing / alignment.

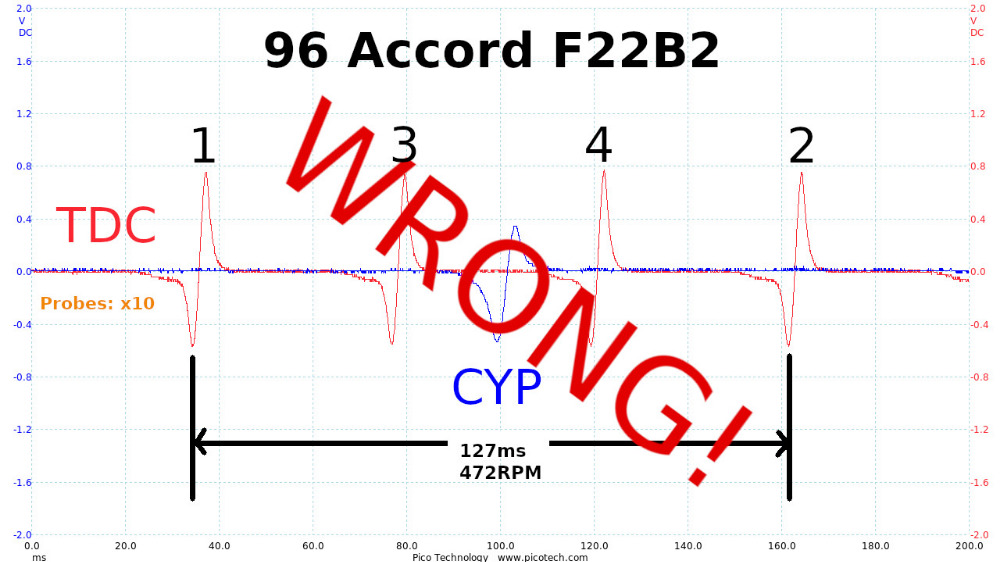

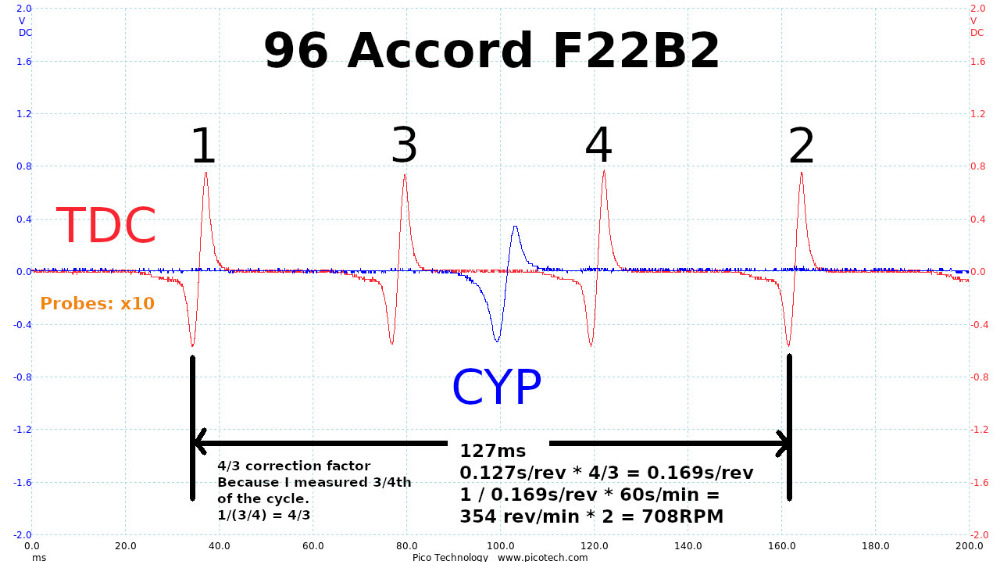

Here is a sample of the TDC vs CYP signals on my 96. If my measurements and calculations are correct, this would be about 708 RPM. It's not obvious from the signals, but if it was running at 708 RPM it was running like GARBAGE! It always does.

The calculations above were based on a measurement mistake. I was only measuring 3/4th of a cycle and didn't realize it. I also forgot that it wasn't just about how much time it takes to complete 1 cycle. It is also about what happens during that time. Basically what happens in that time is that the cam spins once and the crank spins twice. Engine RPM is measured in crank RPM, not cam RPM. Thanks to Guafa for pointing that out! Here is the correction:

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

Here is the set up. I added some more sealant to the polycarbonate on the intake side so that the intake wouldn't have an air leak.

I also plugged the Exhaust backpressure hose with tape as well as the vacuum line for the EGR valve to prevent air leaks.

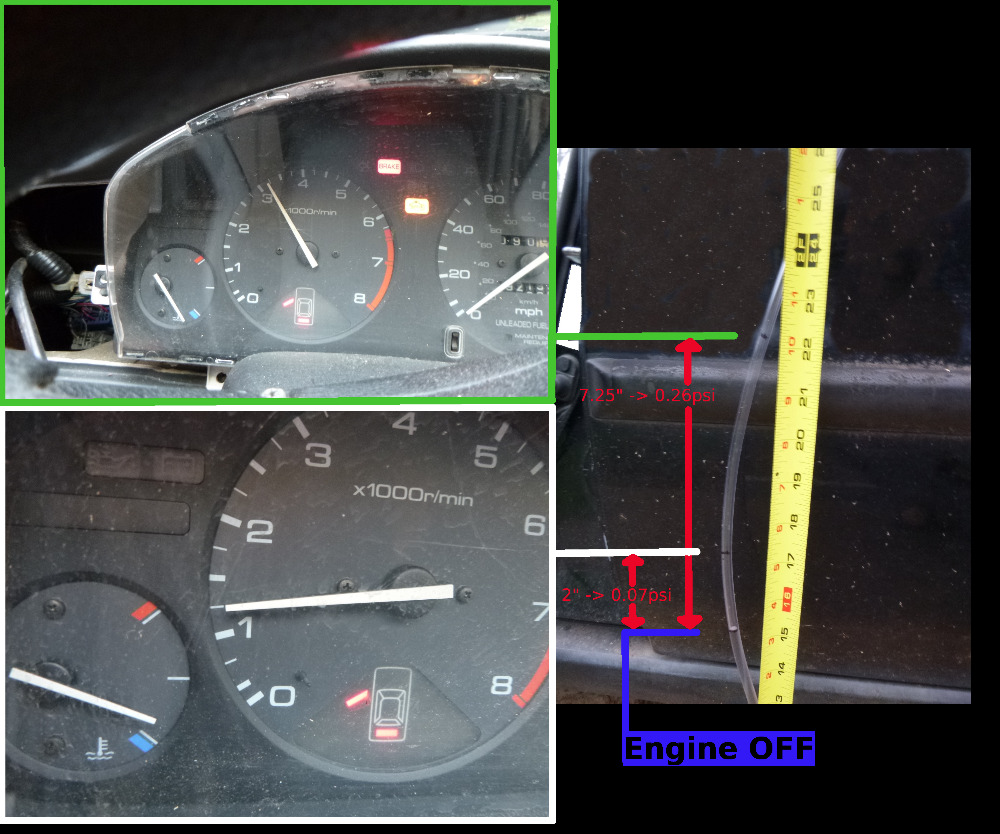

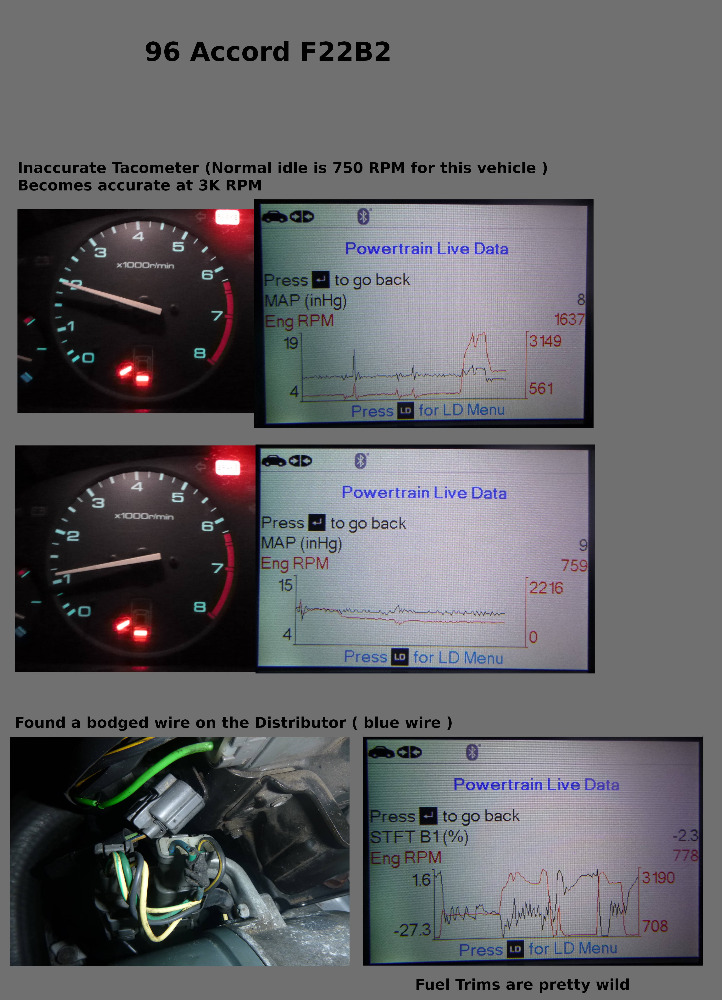

It turns out that the tacometer has been lying to me!

EDIT: ==============================================

Based on the correction of my measurement mistake above, this section no longer makes as much sense as I used to think that it did.

However I will leave it here for the sake of learning. Sometimes you can learn a lot from watching someone do it wrong ( as long as you know that it's wrong ).

==================================================

This changes everything! The engine wasn't dying because of misfires ( well not directly anyway ). The engine was dying because I was using the tacometer to try to make it idle at 750 RPM. But in reality it was idling at about 472 RPM ( as seen in the post above ) which is WAY too low! This explains SO much! The way I did this BTW was basically just by exploiting the fact that it was running terribly! There is no magical way to use the tacometer to make an engine idle at a lower speed. I just used the throttle to make it run poorly enough to get the tac down to 750 ( which was really more like 472 ).

It explains the misfires ( The ignition system is not designed to run at RPM's that low )

It explains the mis-behaving timing light ( for the same reason )

It explains the rough running and wild fuel trim behavior ( for the same reason )

It explains the wild secondary ignition patterns while having an other wise healthy ignition system ( for the same reason )

It also explains why I can't find a problem with any of my engine's signals ( because there is no problem with the signals that I checked ).

Edit:+++++++++++++++++++++++++++++++++++

That ends the no longer correct section.

++++++++++++++++++++++++++++++++++++++

Edit:==================================

Ok, so now that I realize my measurement mistake it changes a lot about what I previously said above in that edit. Here is what probably was really happening:

======================================

It was idling slightly lower than normal, but not by much according to the manual 700RPM is in normal range.

However it was sucking exhaust in from the EGR valve ( I'm not sure why yet, it does not appear damaged or stuck ).

This was causing various types of misfires and causing the fuel trims to go wild while also affecting spark timing.

I'm not sure what caused the timing light issue. It might be the timing light itself. I couldn't reliably reproduce it.

I did find that after bypassing the EGR valve that it idles reliably between 650 and 750 RPM, so I think it is clear that the EGR valve was a problem.

The inaccurate tacometer played a key role in my confusion here. I didn't realize that the car was idling, so I didn't think about idle problems. Instead I was thinking about a misfire bad enough to cause it to run that badly at higher rpms ( which was never reality ).

EDIT:+++++++++++++++++++++++++++++++++

Ok, that ends the edits for this post. I believe that the rest is still valid.

+++++++++++++++++++++++++++++++++++++

So now this changes my whole mode of thinking.

Before I was trying to troubleshoot a mysterious misfire, that's no longer the case.

Now I'm trouble shooting an inaccurate tacometer, idle problems and wild fuel trims.

Right now I'm going to trouble shoot in this order:

1. Inaccuate tacometer

2. Idle problems

3. Fuel trims

I'm still getting rained out... so for now I'll study the details of the Tacometer circuit and see what I can find out.

Maybe I missed a ground when I re-installed the engine.

Maybe that bodged wire that I found is a problem.

Lesson learned!

I'll never trust a tacometer again!

Also, unlike before I wasn't able to get it to idle too low. It idled right at 750rpm and stayed there the whole time. This might be because of the EGR bypass, but time will tell.

Please Log in or Create an account to join the conversation.

- guafa

-

- Offline

- Platinum Member

-

- Posts: 477

- Thank you received: 80

About your TDC vs CYP:

A complete camshaft revolution starts from cylinder #1 pulse and end to cylinder #1 pulse.

Note that you are counting 270 degrees instead of 360 degrees. That is, between pulse #1 and pulse #3, there are 90 degrees. Another 90 degrees between pulse #3 and pulse #4

Please Log in or Create an account to join the conversation.

- guafa

-

- Offline

- Platinum Member

-

- Posts: 477

- Thank you received: 80

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

My calculation of 472 RPM is wrong because my measurement is wrong. I needed to measure all the way back to cylinder 1 ( which doesn't appear on that chart ). I can mathematically adjust it and fix it now that I realize that I'm really only measuring 3/4th of 1 full cycle.

I also got confused and forgot that in the time that 1 cycle completes, the crank shaft turns twice.

The correct figure for that chart is 708 RPM.

I went back and fixed / modified all of my posts that my mistake affected the best that I could ( including this one ).

Thanks Gaufa!

Please Log in or Create an account to join the conversation.

- hakachukai

-

Topic Author

- Offline

- Premium Member

-

- Posts: 84

- Thank you received: 28

I tried to pack as much info into the image as possible so that I wouldn't spam Danner's forum with so many images. But as you can see from the image, measurements and calculations, there is nothing wrong with the tac signal. It looks like a case of an inaccurate tacometer. I don't know if there is an easy way to fix that, but I'm going to ignore it for now. At least now I know that it's not going to affect the engine.

Please Log in or Create an account to join the conversation.