[Fixed] 2006 Mercedes CLS55 AMG O2 Sensor Codes

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

I have three O2 sensor codes as read by my Autel DS708 on the OEM side:

P200C-1 G3/4 (Right O2 sensor, before TWC [KAT] Aging, correction variable exceeded: Delay time too long (P2096)

P200E-1 G3/6 (Right O2 sensor, after TWC [KAT]: Level is above applicable threshold (P1999)

P200E-2 G3/6 (Right O2 sensor, after TWC [KAT]: Level is below applicable threshold (P1999)

I have a subscription to AllDataDIY, as well as the factory Mercedes WIS, ASRA, and EPC software that someone gave me. Unfortunately, I don't have the diagnostic module or wiring diagram module for my Mercedes service software, but Alldata gives me the factory wiring diagrams.

According to what I could gather from AllData, these codes indicate a worn/slow downstream O2. Visual inspection revealed oil leaking from the rear main seal that filled the sheathing of the downstream O2 sensor on the right side. I replaced both upstream and downstream sensors with Bosch (OEM) sensors on the right side just to be sure but....the codes came back. Failure!

Mercedes is a bit greek to me but I figured O2 sensors are O2 sensors and this seemed pretty simple...until I didn't fix the problem with two new O2's. With 120K it doesn't hurt to have an O2 sensor refresh just to keep it running at peak but I need to fix the problem too.

Scan data indicated rich/lean cycling on the upstream sensor, though the signal stays full rich longer than it stays lean on the scan tool. It looks like /---\/---\/---\/---\ whereas the left side looked normal: /\/\/\/\/\. The downstream sensor stayed fairly steady but sometimes around 150mV and sometimes at 600mV or so and I am able to get reaction out of it with throttle snaps, etc.. The left side (the good side) upstream sensor cycles rich-lean evenly but don't recall what the downstream sensor was doing other than I recall not being concerned with cats so it was steady.

Does anyone here understand the fuel control strategy on these that could give me some direction? From what I can tell it does use the downstream sensors for Lambda control which is why I went ahead and replaced the downstream sensor. Alldata mentions that the P200E code can actually cause the P200C code. The one thing I did not do, and I'm kicking myself for it, was check for heater voltage at the sensors. I had no heater DTC's so I took the shortcut and didn't check to make sure heater voltage/current was getting all the way down to the sensors. In the test prerequisites one of the things the PCM has to see is "no fault with oxygen sensor heating" so that also made me think it wasn't a heater issue. Fault setting condition for the P200E is "With two-sensor control switched on, sensor status change must be detected after approx 190s." Fault setting condition for the P200C is "approx. +/-1.0s (+/-TV)." I haven't been able to figure out what "TV" means.

On the OBDII side, the code I have is P2096 Post Catalyst Fuel Trim Too Lean Bank 1. The OEM P200E codes don't seem to be setting a P1999 on the OBDII side as the OEM code description indicates.

I don't have the vehicle right now and not sure when I'll get it back (I'll get it back soon, though) but wondering if there are any Mercedes folks out there that can provide a little direction for me. My first check will be the heater circuits but wondering if there is anything else that can set these three codes.

Thanks,

John

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

Please Log in or Create an account to join the conversation.

- matt.white

-

- Offline

- Elite Member

-

- Posts: 220

- Thank you received: 29

If you have no heater codes, I wouldn't sweat it. I think you'll find they'll be fine.

Did all 3 codes come back or just the codes for the rear 02's?

Did you notice or record what the fuel trims were like? Is there snapshot data you can access and see what the car was doing idling/hard acceleration etc when the codes set?

Sorry, not merc specific, but within reason it's all pretty similar.

Can you access obd2 data? Does this car support it? I'm not sure where you're located sorry.

Sent from my iPhone using Tapatalk

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

I'm in the US...NC to be more specific. It's a US model vehicle. Yes, all three codes returned. I did look at fuel trim data and everything looked normal at idle and 2500-3000 RPM.

I recall there was snapshot data for the OEM codes but I need to look again. When I get the car back that's where I'm going first, of course. It does support OBDII data. When I looked in OBDII data the only code stored was P2096 Post Catalyst Fuel Trim System Too Lean Bank 1. According to the P200C OEM DTC description I figured that's due to the P200C code, though. The Alldata code descriptions list P2096 and P200C being the same thing and give the Aging O2 sensor code description. I think the Autel is incorrectly describing the OBDII code. When using the MB service info, troubleshooting the P200C code along with P200E codes, the service info says the cause is the downstream sensor and that the P200C code is due to the downstream sensor.

It's confusing due to the two sensor fuel control on this vehicle. From what I can gather, now realizing I made a bad call, the downstream sensor needs to cross the 450mV threshold every minute or so. I don't have the vehicle in order to view the data and see what it's doing. I'm trying to gather some info and knowledge before I get the vehicle back.

Below are the MB service info docs I'm working from which led me to the bad call of replacing the O2's. I suspected the downstream O2 but replaced both of them just to make sure but it didn't do any good. That's why my next step was going to be to connect the Vantage Pro to the heater circuit and make sure the ECM is duty cycling the heaters properly...which I should have done prior to replacing the O2's but live and learn, I guess.

Thanks,

John

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

If the current consumption of the heater is not correct then the causes they list are Fuse 43, circuit 87 relay, engine, heater circuit wire issue or the O2 sensor. I checked the info for the left side sensors and they use the same fuse 43 and circuit 87 relay so I suspect there's not a problem there since I'm not getting codes for the other side. So, I'm left with either a signal wire issue or heater circuit issue. I'm just wondering if there is something else I'm missing that the MB documentation doesn't discuss that can cause these codes...

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

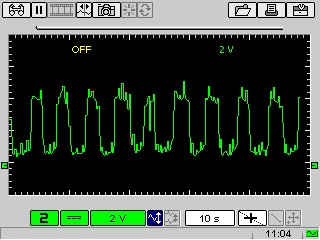

Here is my 'known good' bank 2 upstream sensor at about 2500RPM:

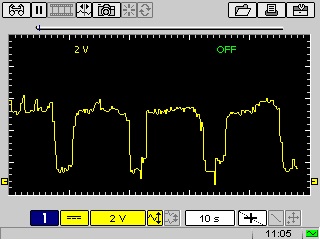

Here is my bank 1 upstream sensor at about 2500RPM. As you can see it stays rich while the other bank drops lean and back to rich in the same time frame:

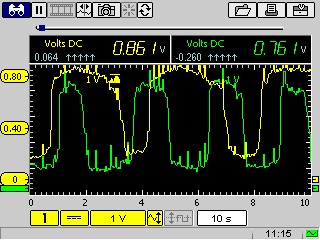

Not sure it's helpful but here is a screen shot of both banks at the same time at about 2500RPM:

So, what would cause the O2 to stay rich like that on bank 1 for longer than bank 2? Long term fuel trim on bank 1 at idle is about +4.8 and short term is around 0.0. If I run the RPM up to 2500 the long term stays around +4.8 and short term goes up to around +7-10%, indicating to me a slight lean condition on bank 1 at higher RPM's.

It doesn't appear to me to be a vacuum leak. What would cause a slight lean condition on one bank and not the other that gets worse with higher RPM? The two items Paul always talks about are MAF and fuel delivery. There is no MAF that I can find. Could it be a dirty fuel injector? It is supercharged and I cannot find a MAF on this engine. Does anyone have any thoughts?

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

Even on a vehicle that has never had problem O2 sensors age and slow down and can drift out of calibration due to deposits and wear and tear and deposits on the internals of the sensor. An O2 is a tiny fuel cell which has a tiny internal catalyst on the surface of which a chemical reaction takes place. The other problem that can occur is the electric heating element or its supply circuit can fail this normally causes the sensor to take several minutes and higher RPM to start working.

After the engine is started from an O2 sensor has to warm up to come alive, when the engine reaches working temperature the ECU monitors the number of times the upstream O2 sensor signal crosses through 0.5v in a given time if after X minutes the crossing counts have not exceeded the required number the ECU flags up a fault code.

A sensor that has covered 100,000 miles will generally be serviceable have slowed down a little and the peak and minimum voltages won't cover as wide a range.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

Andy.MacFadyen wrote: The two upstream sensors B1S1 and B2S1 control the fueling the downstream sensor are there to monitor that the catalyst is cleaning up the exhaust.

Even on a vehicle that has never had problem O2 sensors age and slow down and can drift out of calibration due to deposits and wear and tear and deposits on the internals of the sensor. An O2 is a tiny fuel cell which has a tiny internal catalyst on the surface of which a chemical reaction takes place. The other problem that can occur is the electric heating element or its supply circuit can fail this normally causes the sensor to take several minutes and higher RPM to start working.

After the engine is started from an O2 sensor has to warm up to come alive, when the engine reaches working temperature the ECU monitors the number of times the upstream O2 sensor signal crosses through 0.5v in a given time if after X minutes the crossing counts have not exceeded the required number the ECU flags up a fault code.

A sensor that has covered 100,000 miles will generally be serviceable have slowed down a little and the peak and minimum voltages won't cover as wide a range.

All that is why I originally replaced all four sensors. The codes came back after less than a week. This vehicle has four brand new OE Bosch sensors installed. I haven't checked the actual heater circuits but I don't have any heater circuit codes, either.

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

Please Log in or Create an account to join the conversation.

- John Clark

-

Topic Author

- Offline

- Premium Member

-

- Posts: 139

- Thank you received: 46

What's interesting about this exhaust leak is there is no soot around the crack and the car is nice and quiet. It's obvious it's the problem, though, and am hoping someone can weld it for him as I don't have a welder.

I appreciate everyone's help here, though, and wanted to post the fix.

Thanks,

John

Please Log in or Create an account to join the conversation.