Using a Piezo sensor to identify a noisey valve.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

I thought I would throw this out there for discussion. I have a 2007 Hyundai Sonata 2.4L. The Customer Complaint is "loud pinging sound in the engine". You can, clearly, hear a lifter tapping. I checked the oil and added 2.5 qts. Capacity is 4.5 qts.

Credit where credit is due, I recently watched a video in which Brin Kline used a knock sensor (building on Hans Jorgensen's pulse sensor method) to determine which valve was making noise. So, I set out to see if I could determine which valve is the culprit.

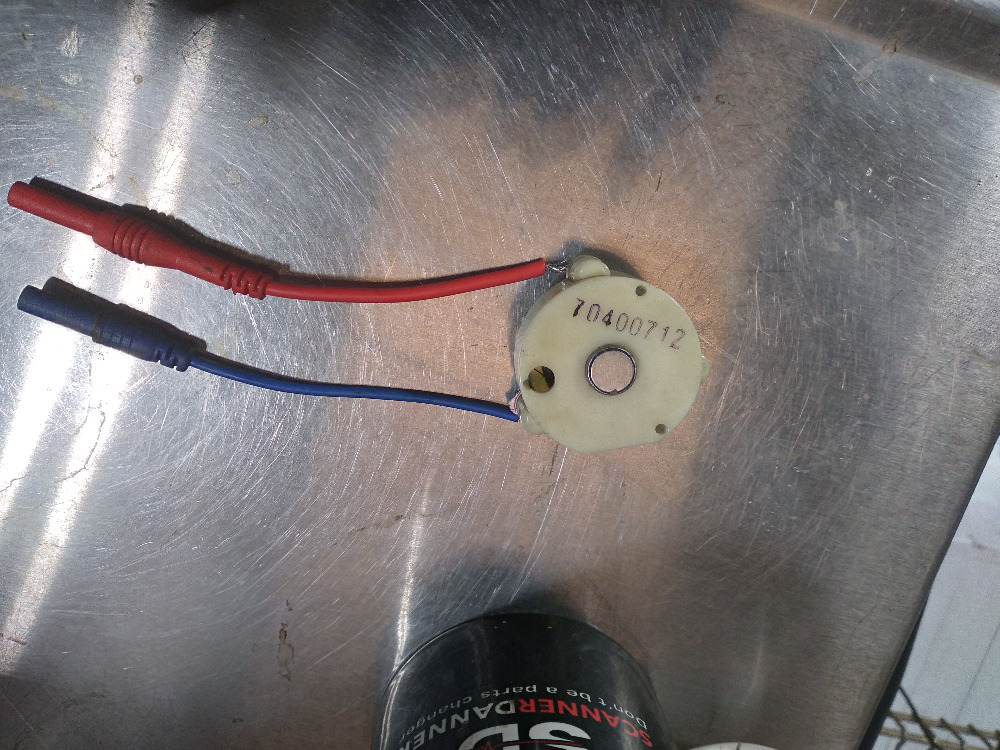

I removed the Piezo (siren) from an old smoke detector and glued a magnet to it.

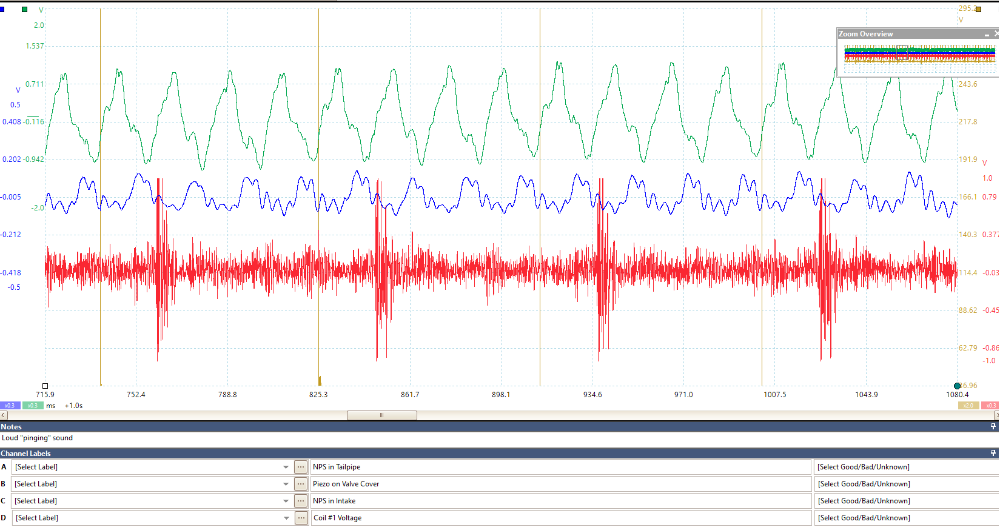

With the piezo stuck to a Valve cover bolt, I could clearly see the tapping in the piezo waveform when the engine was running.

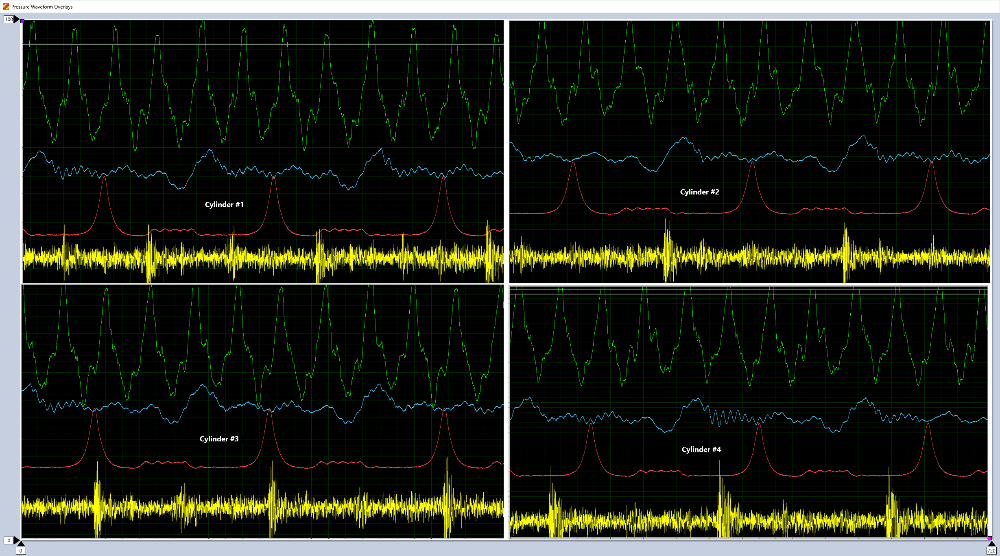

Firing Order 1-3-4-2

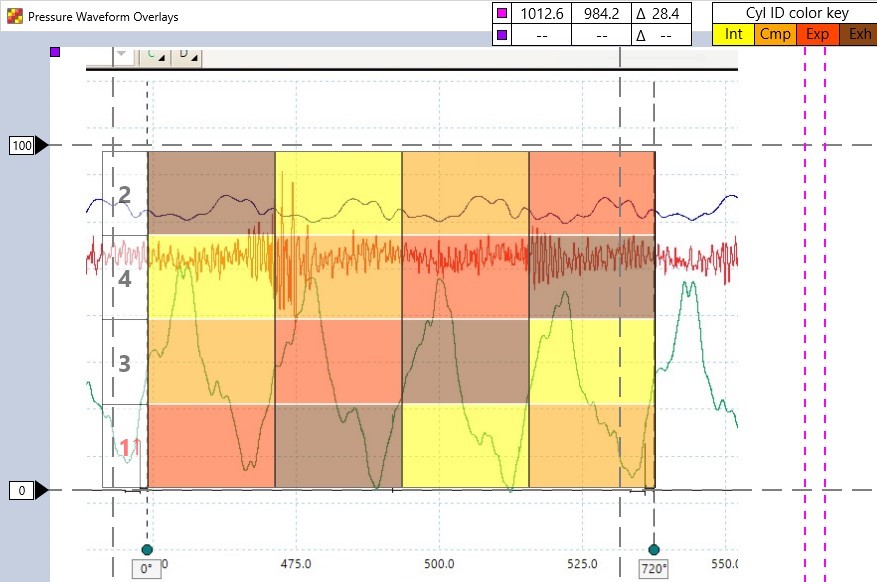

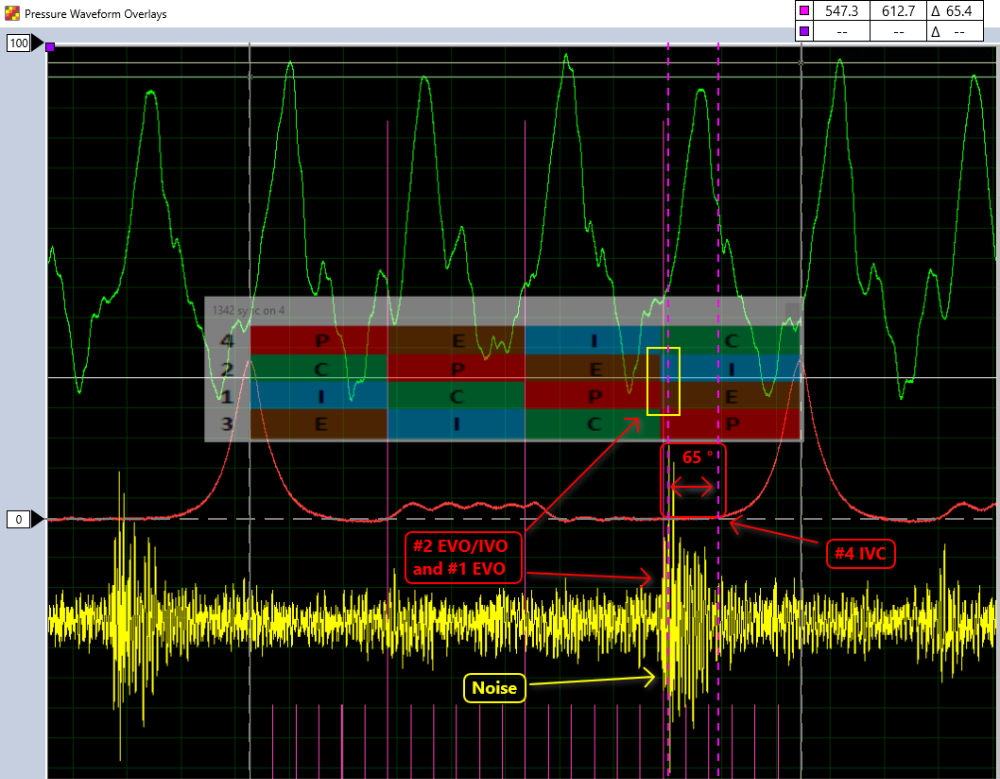

I jumped right to In-cylinder and determined that the culprit had to be:

1) the exhaust valve opening on Cylinder #1

2) the exhaust valve closing on Cylinder #2

3) or, the intake valve opening on Cylinder #2

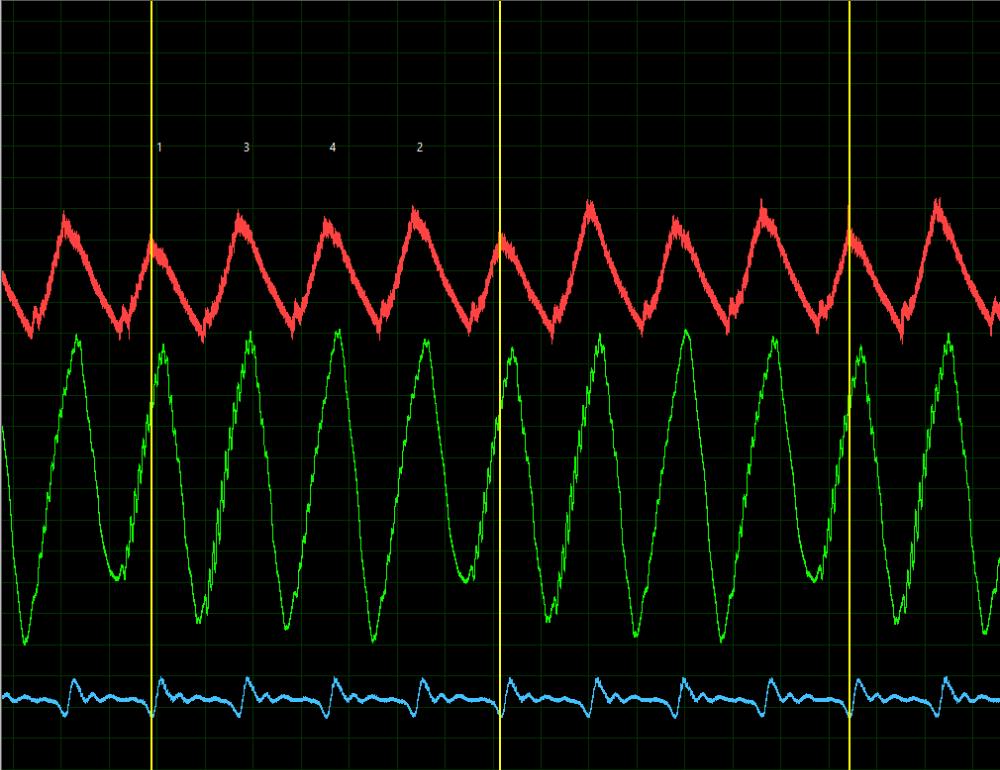

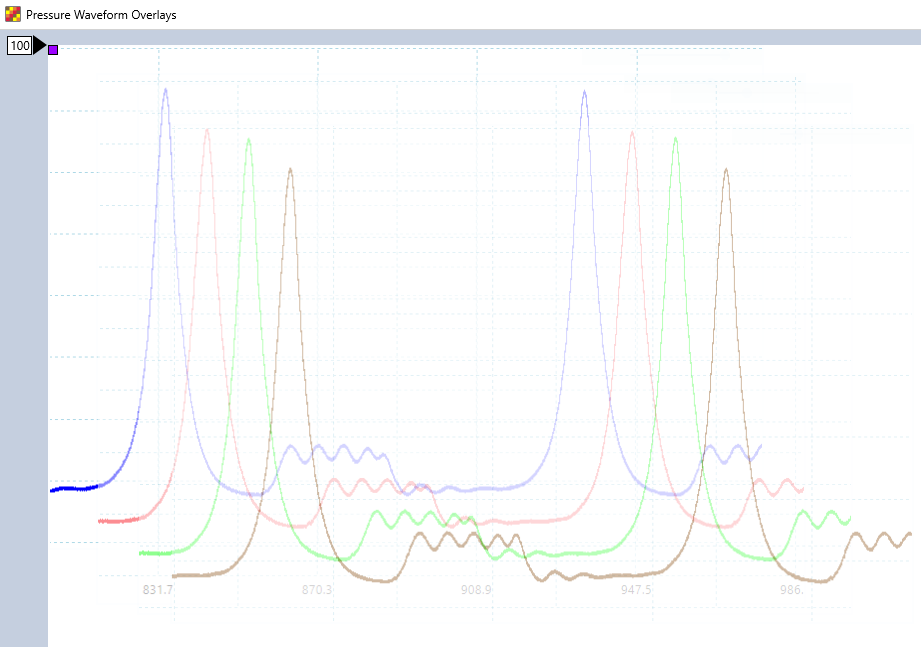

INTAKE, EXHAUST, IN-CYLINDER, PIEZO on valve cover

Then, I got the pulse sensors out.

#1 Sync

RC shows Cylinder #1 low.

I am, also, seeing #3 INTAKE pull being low.

Exhaust

At first, I thought #1 Compression is leaking into the intake through the intake valve. That would explain the low vacuum pull on #3 (extra volume).

But, it's the Exhaust valve that's making the noise? I see no anomalies in the exhaust pattern. (except for when I had a transducer In-cylinder.)

I pulled the valve cover but, nothing was visibly wrong. The cam and tappets(?) looked fine. Chain is tight.

None of this is matters to the diagnosis. I'm just having fun, at this point.

So, if anybody made it this far, what do you think?

Pico files

eScope files

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Wightscope

-

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

I built a stethoscope for my pico sensors collection last year,

it was based on based on this guys design

Here he discusses using it in conjunction with the frequency side of the pico to be able to identify which pulley is making the noise.

I have only experimented with it so far to locate a missfire, but it would seem like a really powerful tool. He has a lot of other really well thought out DIY stuff to make before paying out for the equivalent top end gear.

Like the idea of the magnet, that would probably work combined with a knock sensor.

Please Log in or Create an account to join the conversation.

- Wightscope

-

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

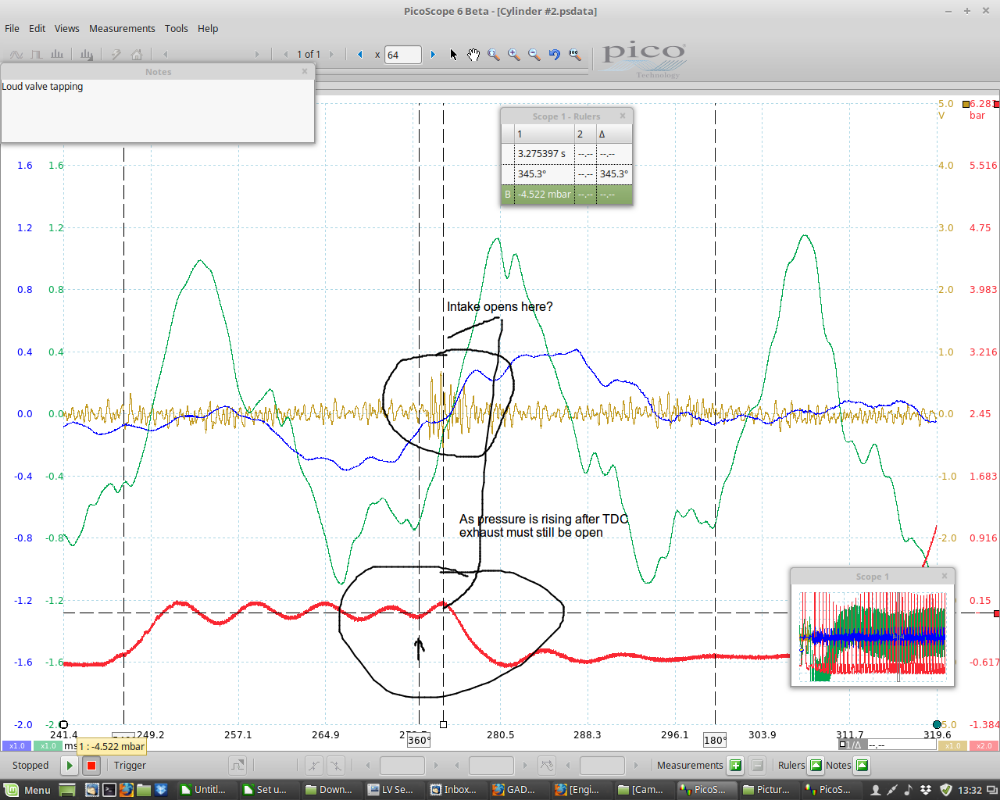

I think it is too late to be the exhaust valve on 1

agree on cyl 2 though I lean more towards intake valve as there seems to be noise on both open and close.

What's the blue trace on the pico files? I thought it was intake but only seeing one big event every 720. (sorry if it's noted in the pico file I have Linux on home PC so limited to ancient version of Pico 6)

Still thinking about it!

Looking at cyl 2 if I have this right as the pressure continues to rise after the piston is at TDC then the exhaust must still be open and the intake opens where the peak is - which is right in the middle of your noise reading

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Wightscope wrote: I think it is too late to be the exhaust valve on 1

agree on cyl 2 though I lean more towards intake valve as there seems to be noise on both open and close.

I have tried to look at it as being #2 Intake. The event does align with the intake valve event but, then , I can't explain #1 Low Compression, or #3 Low Intake pull.

The Blue trace is Exhaust. The Pressure Transducer impacts the shape of the exhaust waveform. This is why I, rarely, do In-cylinder at the same time as Intake and Exhaust pulses. You'll notice the pattern of the Blue Exhaust wave shifts with every cylinder waveform. The Anomaly does its thing right during the Exhaust/Intake valve overlap, on every In-cylinder waveform.What's the blue trace on the pico files? I thought it was intake but only seeing one big event every 720.

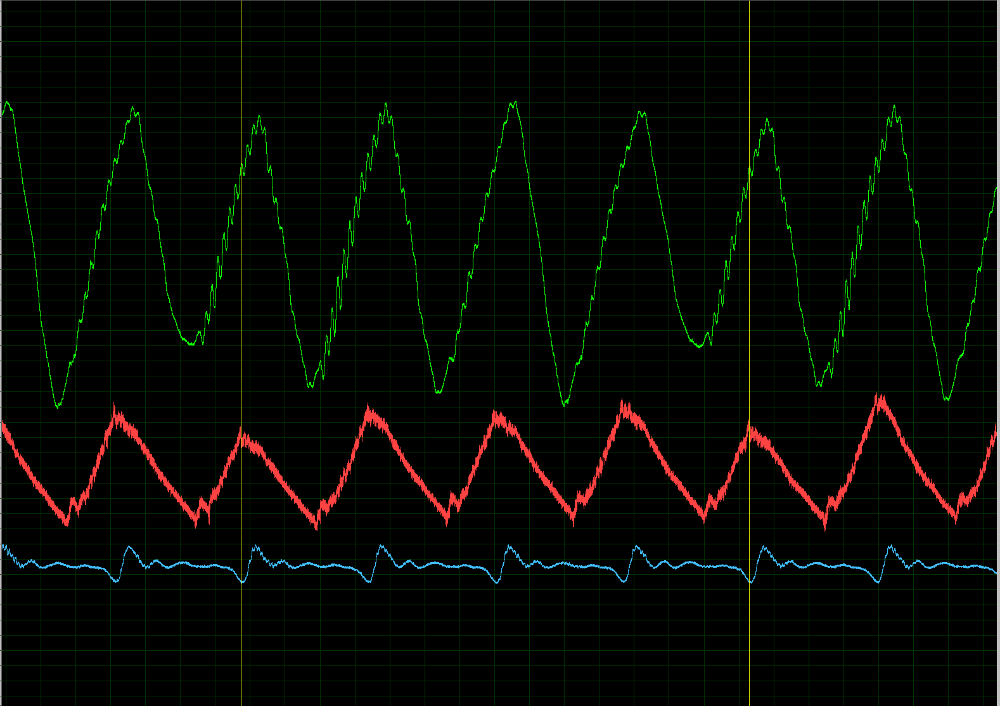

This is the Exhaust waveform, without a transducer in any cylinder. It looks uniform, to me.

Intake, RC, #1Coil.

Me, too.Still thinking about it!

Thanks for your input, Wightscope!

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Wightscope wrote: Here he discusses using it in conjunction with the frequency side of the pico to be able to identify which pulley is making the noise.

Thank you! I love the concept, here. This gives me something new to play with.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Wightscope

-

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

One thing that does occur to me looking at it again is that the lower draw in the intake is not happening in the cylinder - only in the intake.

On the in-cylinder it looks like No 1 is opening the exhaust valve some 16 degs BBDC vs 9degs on No2 duration also looks to be longer as the final "hump" in the exhaust section is in vacuum indicating that the intake has opened already - which I believe would account for No3 reduced intake pressure. Jammed follower ?

Note also that the compression differences are wide at 6.2, 6.8, 7.2, 6.4 - too me looks like 1 and 4 are down.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Chad wrote: Credit where credit is due, I recently watched a video in which Brin Kline used a knock sensor (building on Hans Jorgensen's pulse sensor method) to determine which valve was making noise.

That was an interesting one.

Chad wrote: I jumped right to In-cylinder and determined that the culprit had to be:

1) the exhaust valve opening on Cylinder #1

2) the exhaust valve closing on Cylinder #2

3) or, the intake valve opening on Cylinder #2

Or #4 IVC. And #4 intake pull isn't as bad as #3 but isn't as deep as 1 and 2 either. So I'm going with #4 intake for the noise.

Chad wrote: The event does align with the intake valve event but, then , I can't explain #1 Low Compression, or #3 Low Intake pull.

Neither appear to be related to the noise. #1 intake valve leaking would explain both.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Neither appear to be related to the noise. #1 intake valve leaking would explain both.

That's what I was thinking. I'll have to go back and re-look at #4.

Thanks for the input.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

However, I still can't decide between #2 EVC/IVO, or #1 EVO, either.

#1 shows low RC

> Makes #1 EVC the Prime suspect.

#3 shows low Intake

>I'm still struggling with that. :dry:

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Wightscope

-

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

- Would (damn I need one of those overlays for Linux!) late closing of the exhaust valve on 1 would effectively allow exhaust gas to be drawn from the exhaust to the intake at the same time as 3 was on intake stroke.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Wightscope wrote: Did my theory above of No 1 Exhaust opening early and closing late not make sense?

I'm with you on a Late EVC increasing EGR and making the intake pull low. However, I'm not seeing an early EVO. Give me a few minutes to go down that avenue.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Chad wrote: There he is! Welcome to the party, Matt T!

You know I ain't gonna miss a pico party :lol:

Chad wrote: #1 shows low RC > Makes #1 EVC the Prime suspect.

I'm not seeing how a loose exhaust valve could cause low compression.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

Wightscope wrote: Did my theory above of No 1 Exhaust opening early and closing late not make sense?

- Would (damn I need one of those overlays for Linux!) late closing of the exhaust valve on 1 would effectively allow exhaust gas to be drawn from the exhaust to the intake at the same time as 3 was on intake stroke.

Your theory doesn't fit #1 exhaust being the noisy one. The loose valve will be opening late and closing early. That isn't to say there isn't something wrong with #1 exhaust. If the motor has solid lifters maybe someone has already been in there and shimmed that valve too tight??

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

This leaves no room for an "Odd-man-out" vacuum pull.

I am stuck on. #1 Intake valve is leaking on compression. The lost volume from #1 leaks into the Intake during #3 Intake stroke.

This doesn't align with the noise, though.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Matt T wrote:

Chad wrote: #1 shows low RC > Makes #1 EVC the Prime suspect.

I'm not seeing how a loose exhaust valve could cause low compression.

If the exhaust valve was not sealed, compression would leak into the exhaust. I don't see that, though. I see it in the Intake. But, I can't align that with the noise.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Matt T

-

- Offline

- Platinum Member

-

- Posts: 751

- Thank you received: 276

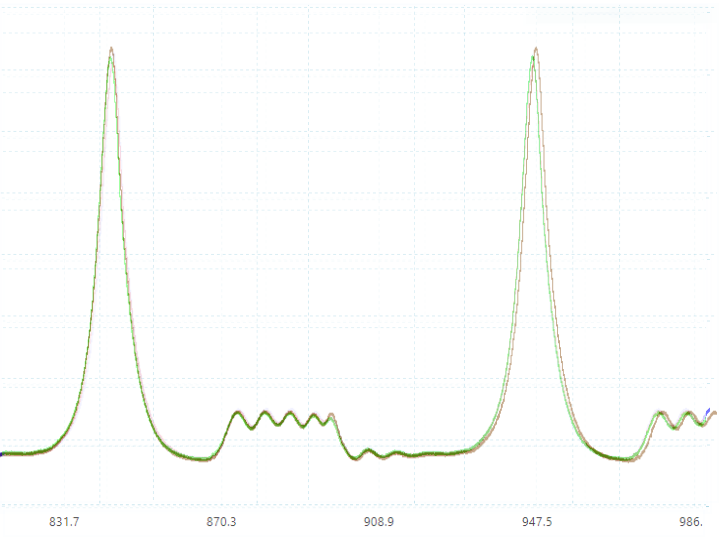

Chad wrote: As far as valve timings go, they are all identical. This an image of ALL 4 In-cylinder waveforms, stacked on top of each other.

Yeah I've been over them trying to find a valve timing problem too. Couldn't find any so took a look to see if this motor is GDI. Found out it ain't GDI but it is 4 valves per cylinder. So we ain't gonna find a bad valve because it's good twin is covering up for it

Chad wrote: If the exhaust valve was not sealed, compression would leak into the exhaust. I don't see that, though. I see it in the Intake. But, I can't align that with the noise.

It doesn't align with the noise. A 14 year old econobox that came in with less than half it's oil might have more than one thing wrong with it :lol:

I think you've maybe dodged a nasty comeback on this one by experimenting.

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Matt T wrote:

Chad wrote: A 14 year old econobox that came in with less than half it's oil might have more than one thing wrong with it :lol:

That's the conclusion I am coming to. I have been trying to align two different problems. :whistle: Oh, well. I can't say it hasn't been fun!

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Wightscope

-

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

Odd that the low compression from the RC is not that visible in the overlay, it was 6.2bar vs 7.2bar when I measured it on the in-cylinder.

Do you have a noise waveform from just cranking not running ?

Please Log in or Create an account to join the conversation.

- Chad

-

Topic Author

Topic Author

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2138

- Thank you received: 719

Wightscope wrote: Do you have a noise waveform from just cranking not running ?

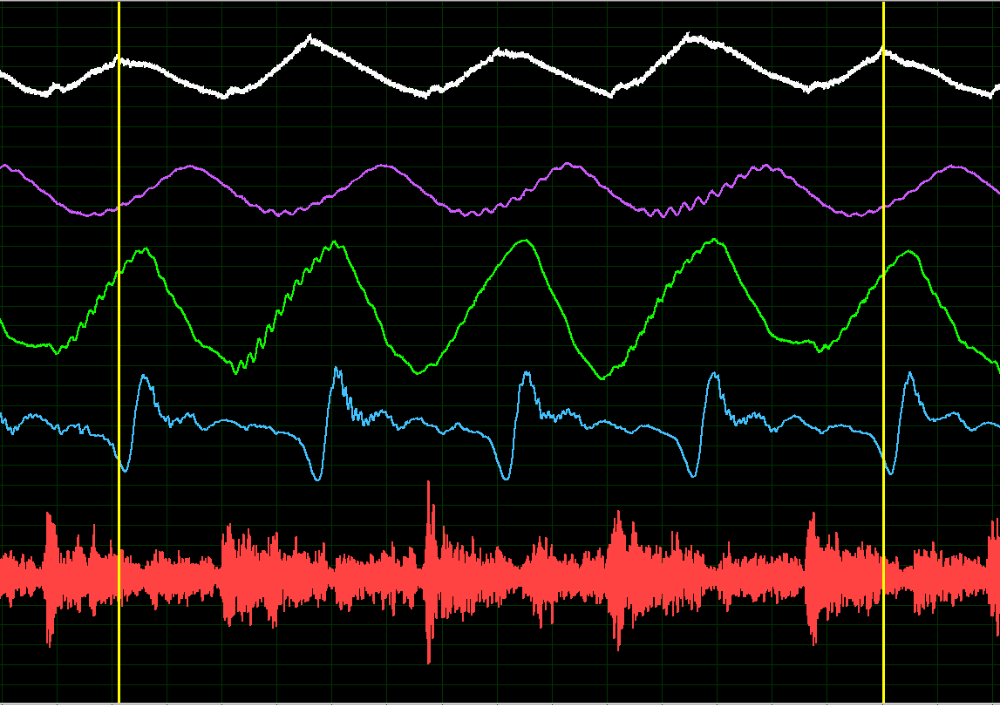

Cranking:

RC, Dipstick Tube, Intake, Exhaust, Piezo, #1 Sync

.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Wightscope

-

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 30

... That I don't have a clue what's making the noise!

Please Log in or Create an account to join the conversation.