[FIXED] Aveo 2007 Rough Idle and Low Vacuum

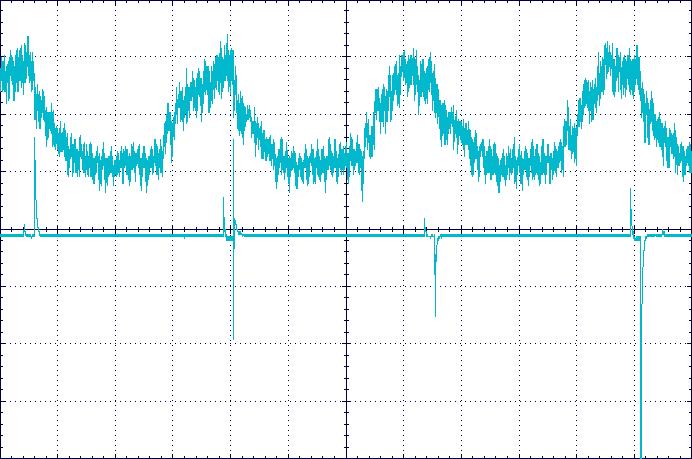

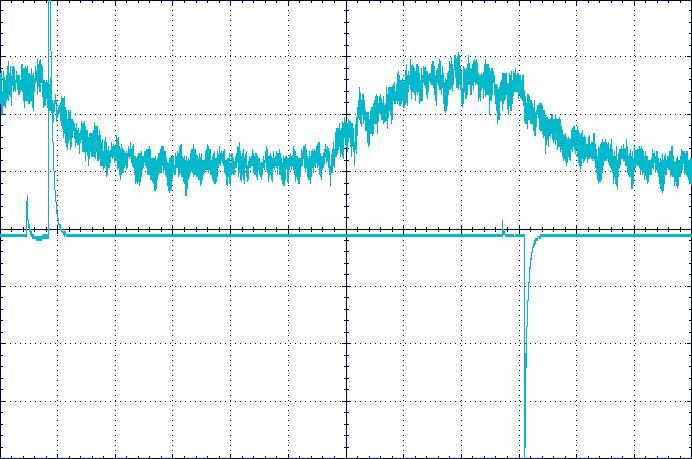

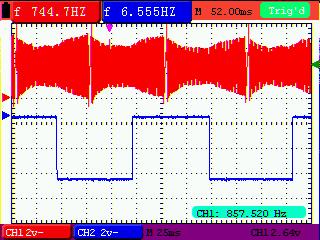

The idle is rough and manifold vacuum is only 14" hg. The timing belt was changed a while ago and the driver thinks that it started after the timing belt change. No misfire codes at this point. I liked the example in PD's book and videos of comparing peak compression to cylinder spark event to determine if the timing is off and did that test. I have a couple of waveform .bmps I would like opinions on. In each, the top trace is a current probe around the battery cable during cranking and the second trace is a capacitive ignition probe around the cylinder 1 plug wire.

Please Log in or Create an account to join the conversation.

At first glance, it looks to me like spark timing is OK. A little bit retarded of TDC, sure, but that may be the default timing strategy on this engine. I'm eager to hear what others think of your captures.

What actually caught my eye was the relative compression waveform itself. The large U-shaped valleys in between the compression humps looks unusual... Kinda reminds me of other captures I've seen on engines with jumped timing. Not saying that's your issue, just thinking out loud.

If you can get to the cam and crank sensors, we can try a cam/crank waveform compared to a known good, and see if there's anything obviously out of alignment.

Please Log in or Create an account to join the conversation.

- cheryl hartkorn

-

- Offline

- Platinum Member

-

- Posts: 692

- Thank you received: 130

Please Log in or Create an account to join the conversation.

I like the cam and crank sensor idea and I will probably try that tomorrow. I didn't try that first because I could not find a known good one.

Please Log in or Create an account to join the conversation.

It runs OK at higher RPMs. I wanted to eliminate all possibility of it being the EGR valve so I used a piece of shim stock to temporaily block the flow and that made no improvement in the idle.

Please Log in or Create an account to join the conversation.

- cheryl hartkorn

-

- Offline

- Platinum Member

-

- Posts: 692

- Thank you received: 130

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

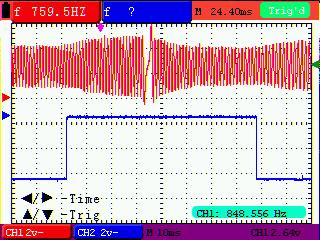

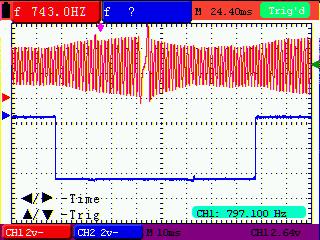

Attached are captures of the crank and cam sensors.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Thank you for the waveform. Is it from an Aveo 2005-2007? Also, it appears to me that mine is off a little. Do you have any thoughts on it?

Bob

Please Log in or Create an account to join the conversation.

Does a power balance test indicate if one cylinder is weaker than the others?

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

I suppose it's possible that one of the cam keyway a sheared off, but the only way to know that would be to remove the cam sprockets...

Only other thing I can think of is that they got the timing wrong the first time around, tweaked the valves on the pistons, and now they're not sealing correctly.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

It looks like the exhaust cam is one tooth retarded, IMO. You can try the ol' golf tee trick and see if you can pop the cam back into time without taking everything apart.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

RH6400 wrote: Thanks for the response Tyler. Can you describe the golf tee trick? I can guess the general idea but I would like to know the details.

Sure! Basically, you put a golf tee (or the smooth end of a drill bit, whatever) into a valley of the belt sprocket, and rotate the belt so the drill bit/tee ends up under the belt, and gets dropped out the other side. This ends up making the belt jump a tooth on that sprocket.

You insert the bit/tee into the side of the sprocket that you need to rotate towards. In other words, if you want the sprocket to advance, you put the bit on the right side of the sprocket and turn the belt counterclockwise. When the bit comes out the other side, the sprocket should have advanced one tooth from it's previous position.

It's a real time saver on timing belt jobs when you don't get it right the first time, but don't want to pull everything apart to reset it. :lol:

Please Log in or Create an account to join the conversation.