Re:Re:Show us your homemade Test Equipment

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 29

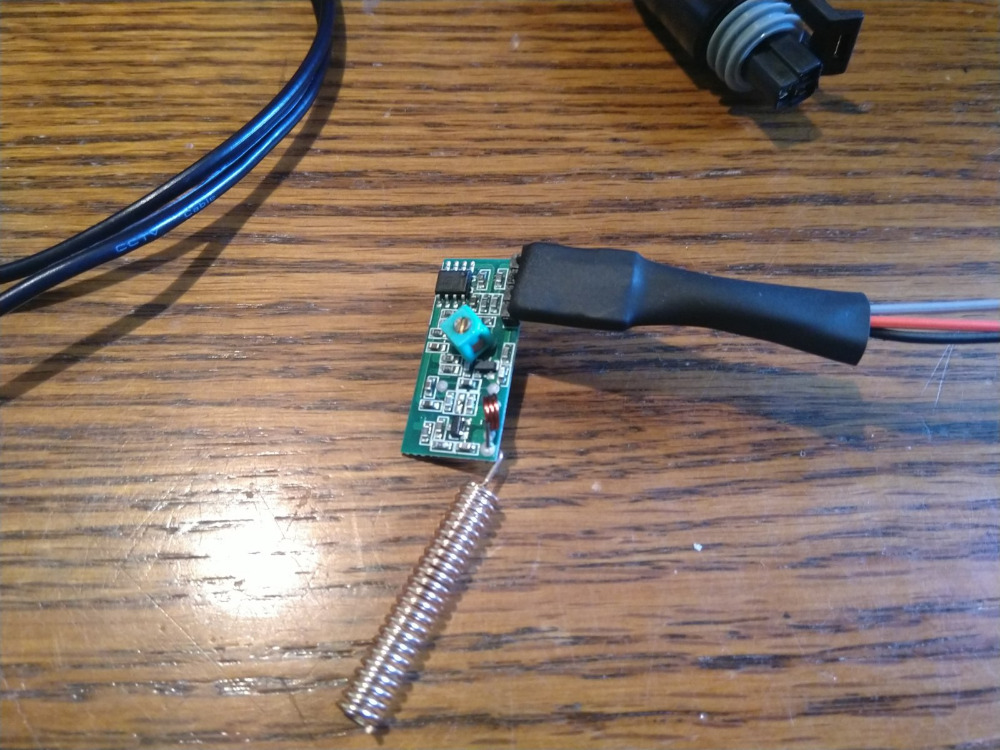

A cheap 433 receiver from ebay is next stop , but I do like to re-purpose OEM kit !

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 29

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 109

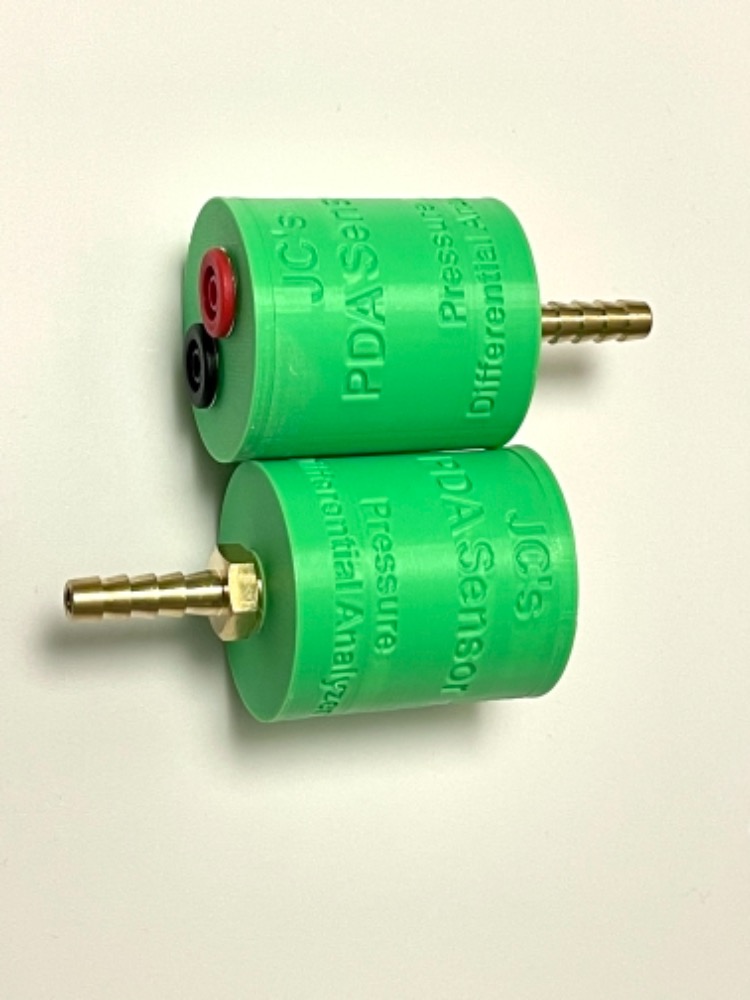

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

- Posts: 4413

- Thank you received: 958

Those look great!John Curtis wrote: I’ve got a whole list of things to develop and make. So far this is it.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 109

Noah wrote:

Those look great!John Curtis wrote: I’ve got a whole list of things to develop and make. So far this is it.

Thanks. Just tuned everything in and fixed the flaws going forward that were in the initial sets. The initial sets are functional but a tiny bit out of square during production. Figured I’d make a holder for them that can double as a way to hold my test leads.

Unfortunately I’ve got about 4 sensors that aren’t perfect visually but have the same functionality.

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

Unfortunately I’ve got about 4 sensors that aren’t perfect visually but have the same functionality.[/quote]

PM sent

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 109

AJeep18 wrote: [quote=

Unfortunately I’ve got about 4 sensors that aren’t perfect visually but have the same functionality.

PM sent[/quote]

Responded.

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- John Curtis

-

- Offline

- Platinum Member

-

- Posts: 344

- Thank you received: 109

Making Pressure Differential Sensors (PDA Sensors) for pressure pulse diagnostics.

Currently servicing Central Texas.

Please Log in or Create an account to join the conversation.

John Curtis wrote: I’ll PM you.

No I'll PM YOU!

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 29

I have been using stackable banana plugs - effectively both male and female so one on the test light one on the earth clamp and all my probes also fit so I can alligator or probe for a jumper.

Also got a 10ft double ended retractable reel that has two wires, one I put stackable bananas on each end, others are alligators.

Just made a cable today for using a phone power bank as a 5v power supply for pressure transducers, added 33ohms of resistance else the powerbank shuts off after 30s. Sadly 150ma was too much for the LED I built in to it!

Please Log in or Create an account to join the conversation.

Wightscope wrote: Just made a cable today for using a phone power bank as a 5v power supply for pressure transducers, added 33ohms of resistance else the powerbank shuts off after 30s. Sadly 150ma was too much for the LED I built in to it!

Good thinking about the resistor. I've had problems with both a power bank and a 18V>12V/5V power tool battery adapter shutting down at low load with my USB>Banana cable. The tool battery adapter was also shutting off the 12V with my 10-30V "transducers". Hacked it to to run 18V straight from the battery to the 12V port.

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 29

Mainly use it via a 12/24v buck to run a Quiko soldering iron set up - that works really well -and I have a Jump starter handy as a bonus.

Most of my transducers are 5v but I just got a 10Bar absolute (ie complete vacuum to +9bar) sensor that is 12v, - going to need a load cable for that too.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

AJeep18 wrote: Beat you to it Tyler

Lookin' good.

Please Log in or Create an account to join the conversation.

Sent from my SM-G781U using Tapatalk

Please Log in or Create an account to join the conversation.

Sent from my SM-G781U using Tapatalk

Please Log in or Create an account to join the conversation.

- Wightscope

-

Topic Author

- Offline

- Premium Member

-

- Posts: 132

- Thank you received: 29

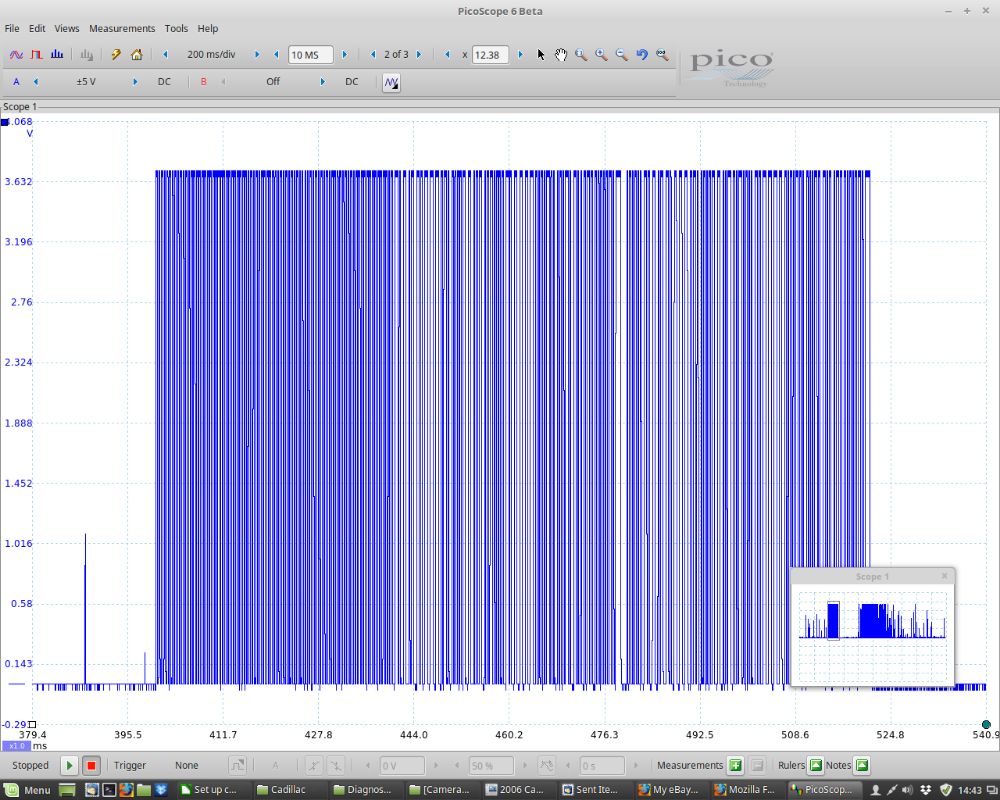

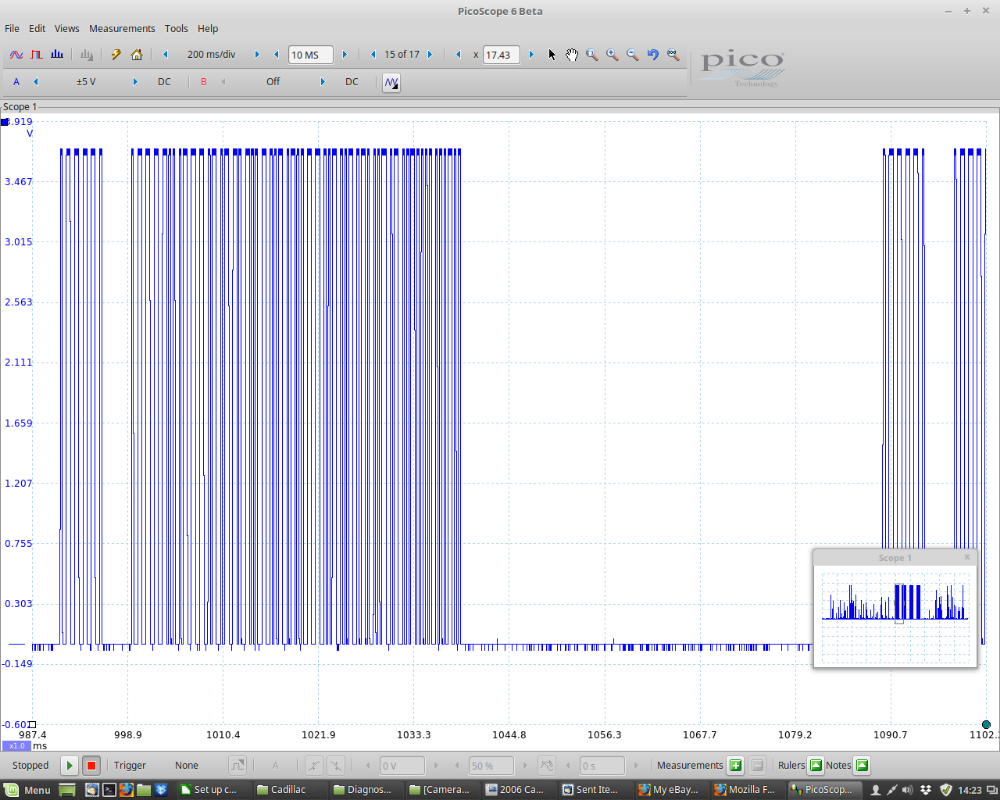

So at 1200rpm a sound at 10Hz is going to be valvetrain as the cams rotate at half the speed of the crankshaft, or maybe an idler pulley bearing - if it is 2/3rds of the size of the crank pulley will make a noise at 13.3Hz

There must be a simple way of detecting which wheel bearing it is by seeing if the frequency goes up or down when turning a corner...

Please Log in or Create an account to join the conversation.

Sent from my SM-G781U using Tapatalk

Please Log in or Create an account to join the conversation.