Fuel Injector Waveform Questions

Please Log in or Create an account to join the conversation.

I'm still unsure why the misfire was so intermittent? And why the trims were positive when the misfire was happening. Usually, a compression loss causes negative trims, in my experience. Did you have the opportunity to do any kind of leak down testing?

Please Log in or Create an account to join the conversation.

The misfire wasn't really that intermittent and now that I know what the problem is everything has fallen into place. The engine would be at it's worse after a cold soak. Once it warmed up it was better, not good, just better. The first time I had it I noticed the oil was low so I topped it off before I gave it back to the owner. I also did the idle, accelerator and throttle plate relearns so I think it ran better than he was used to at first.

Today I pulled the dipstick and oil level was just barely on the stick. Uh-oh #1.

Pulled the spark plugs and 1-3 looked normal, #4 had slight oil cooked on it and was the wrong color, Uh-oh #2

Did compression test and cylinders 1-3 were dead on 180 psi (160 being minimum in this engine). Did #4...120 psi. :sick: Poured some oil in the cylinder and that got it up to 150 psi.

I didn't do any leak down testing. Once I told the owner about the compression results, he decided to throw in the towel and is going to trade it in. He threw a lot of parts at this thing before I begged him to stop and he doesn't want to spend any more money on this car.

The part that really gets me is when he first told me about his problems and the things he had already done, first words out of my mouth were, "I would do a compression test." Guess I lied...because I sure as hell didn't follow my own advice.

Please Log in or Create an account to join the conversation.

rockp2 wrote: Did compression test and cylinders 1-3 were dead on 180 psi (160 being minimum in this engine). Did #4...120 psi. :sick: Poured some oil in the cylinder and that got it up to 150 psi.

Oh, OK! That's not nearly as low as I was expecting. Totally understandable that you might have missed the problem on the relative compression test. Marginal cylinders (as opposed to completely dead holes) can be difficult to pick out sometimes.

I recently got burned on a Fusion the same way. :blush: Relied too heavily on the Ford scan tool relative compression test, which didn't pick up the low(er) cylinder. Couldn't hear it when cranking, but it was there.

I'm trying to get the file to work so I can post the relative compression, but for whatever reason it seems that the file is not complete and is not opening on my computer. Seems like half the time I move files to my puter from my tools I mess something up and lose them. Hopefully I just copied it and I still have the original file on my Verus. I'll take a look because I'd love to know what I missed.

You've got ShopStream Connect on your computer? I've had similar issues getting files off a Verus. Maybe Noah can chime in here...

Please Log in or Create an account to join the conversation.

Sent from my SM-N920P using Tapatalk

Please Log in or Create an account to join the conversation.

- Posts: 4422

- Thank you received: 961

Tyler wrote:

I'm trying to get the file to work so I can post the relative compression, but for whatever reason it seems that the file is not complete and is not opening on my computer. Seems like half the time I move files to my puter from my tools I mess something up and lose them. Hopefully I just copied it and I still have the original file on my Verus. I'll take a look because I'd love to know what I missed.

You've got ShopStream Connect on your computer? I've had similar issues getting files off a Verus. Maybe Noah can chime in here...

I've found that some times it's easier to take a screenshot using the Verus and send it as an email attachment to myself from the Verus. Then I'll open the attachment on my lap top.

You lose the ability to scroll and zoom the capture like you could using Shopstream to view it, but it's easier to pull it up on any device now and show the boss or the customer and say "this is why were going this direction".

And it's easier to post the files to the forum.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Ben, the owner does not want to put anymore into the car, even if adjusting the valves brought it up to 150psi, that would still be below minimum spec of 160. So he's just going to trade it in. But thank you very much for that tip. It will definitely be remembered!

Tyler, referring back to the post concerning the fuel injectors pressure drop,for my future knowledge, how much of a drop indicates a bad or blocked injector? Besides an obvious massive difference? I saw one of Paul's videos where I think he identified a bad injector that was only 2 psi difference? If I am remembering correctly.

Please Log in or Create an account to join the conversation.

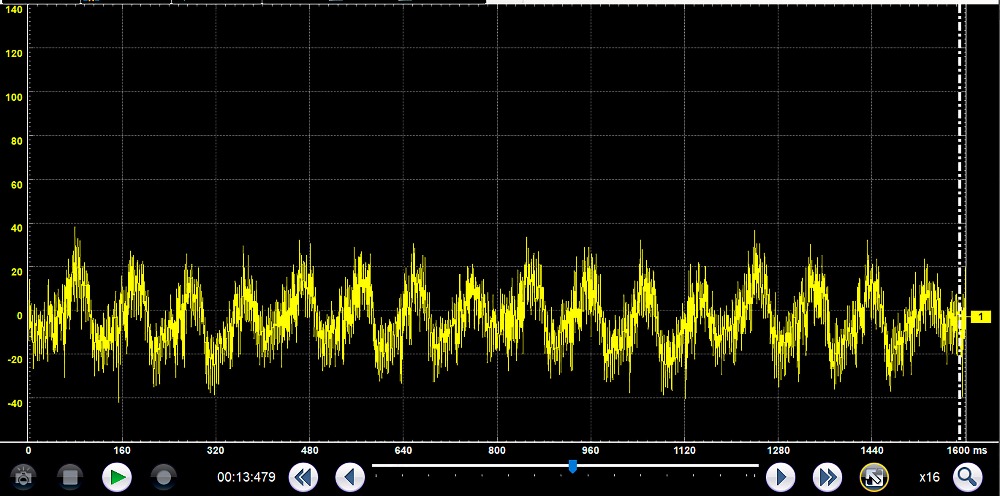

rockp2 wrote: I do have Shopstream on my puter. I did have the relative compression original file on my Verus so I've attached a screenshot. I can also email the movie to you guys if you want to see it. Please let me know what you see that I did not. Don't be apprehensive about being critical please. Regretfully I did not use a second channel to identify one of the cylinders.

I see it? But I also know there's an issue to see. :silly: It's very slight - I'm not sure if I'd have picked that out at first glance. Or, even if I did see it, I may not have pursued it in favor of other diagnostic directions.

Do you recall the settings you used for that capture? Mostly wondering if using the Filter option might have made the peaks less noisy. I dunno if that'd help for sure, just thinking out loud.

Tyler, referring back to the post concerning the fuel injectors pressure drop,for my future knowledge, how much of a drop indicates a bad or blocked injector? Besides an obvious massive difference? I saw one of Paul's videos where I think he identified a bad injector that was only 2 psi difference? If I am remembering correctly.

Yeah, I think 2 PSI was his go-to rule. Dunno if it was in the same video, but I think he also said that when you find a bad one, it's usually way more than 2 PSI off from the others. :lol: It's my experience that the 2 PSI is mostly there to account for testing variables, like fuel temperature and idle time between pressurizing the rail and running the injector.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Its obviously not dead which will be much lower but anytime there's a noticeable low fairly consistently and especially when followed by a higher cylinder in a consistent pattern like that it's time to do a compression test. Also like Tyler mentioned a filter would have helped some on making it more readable

Sent from my SM-N920P using Tapatalk

Please Log in or Create an account to join the conversation.

I don't remember the settings I used. This was my first time doing a relative compression test with my brand new High Amp Probe. But I'm going to be doing some practicing to get it right.

Thanks Tyler and Ben very much for educating me on this. Next time I'm going to move the file to my computer so I can look at it on larger screen then the Verus. Not that I would have caught it (this time).

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.