Home made in cylinder transducer

- Posts: 4417

- Thank you received: 959

I'm pretty sure the Snap On transducer and the one I am using are both 500psi.

I think I have 2 secondary rpm pick-ups collecting dust, I may try to cannibalize one....

I definitely need to do more testing to be able to translate the voltage scales to actually pressure and vacuum.

I will continue post here as I experiment, thank you for your input. It is greatly appreciated!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Also if the aux 0V floats there's a good chance the USBs will too. Something else to bear in mind if you're unable to get a consistent DC reading at atmospheric pressure. I wouldn't tie the 'scopes 0V to 'scope ground but powering the transducer with a wall wart and tying it's 0V to the 'scope ground shouldn't cause any problems. Or at least not any expensive ones :lol:

www.scannerdanner.com/forum/diagnostic-t...sure-transducer.html

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

Thank you once again Matt, owe you a beer

I found the utility in Windows to test various functions of the scope, including the 5v power supply on the aux plug and was able to ID power and ground. I intend to re-pin the Snap-On rpm pick up too utilize it to power the transducer.

Mine isn't power all the time, so I don't know if it powers on when you select an appropriate test lead preset for a given channel or how it works yet.

I Also want to try a "wall wart" as you call it to see if it skews the 0 line compared to the USB ports on the Verus.

I downloaded the PDF and gave it a glance but I will give it a thorough read through this afternoon.

Once again, thank you very much!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

I repinned an rpm pick up for the Verus to supply power and ground to my transducer but the calibration fails every time and the pressure ends up skewed very negative.

I have a couple that output 0.5 volts at atmosphere and it still won't take.

Do you use yours on the pressure setting or volts?

Very nice build by the way. I need some kind of coupler to thread mine into a compression gauge hose.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Paul Marchant

-

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 12

So, some faultfinding is in order.

With the back removed from the d-type, plugged in to the diagnostic tool, with the pressure sensor soldered on, what voltages do you see on the relevant pins (as per the crap picture in my documentation)?

The Verus seems to expect a transducer that outputs 0.5 to 4.5v, with 0.5v for zero PSIG. When it does the 'calibration' thing, it's assuming that the transducer is electrically connected, but with zero pressure on it. This voltage is then deemed to be zero PSI by the Verus / Vantage Pro and 4.5v is full-scale (i.e. 500PSIG if you're in 500PSI sensor mode).

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Paul Marchant

-

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 12

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1031

1/4" Gas looks very similar to 14mm spark plug thread but don't ever mix up the two types.

Also to clear up terminology a transducer is different from a sensor a sensor requires external power, a transducer dosen't require power it is two wire and generates its own voltage.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

Andy.MacFadyen wrote: Also to clear up terminology a transducer is different from a sensor a sensor requires external power, a transducer dosen't require power it is two wire and generates its own voltage.

Three wire voltage output are transducers. 2 wire pressure transducers are usually 4-20 mA loop powered. I can't recall ever seeing one of those on a vehicle but they're the most common type for industrial process control.

www.omega.com/en-us/resources/pressure-t...cers-troubleshooting

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

I did find a brass coupler to marry it to my compression gauge but I think I'm abandoning the refrigerant pressure sensors.

The voltage output at rest is too low to use the pressure scale on the Verus. I ordered the same one (presumably) that Paul has had success with. The seller claims it to have a range of .5-5 volts.

All mine put out .012 at rest.

If faced with the prospect of spending several hundred dollars on a transducer set up, you better believe I'd just live with this setup on a 2v scale, measurement be damned. But for under $20, I'll give this a try.

Thanks for your help guys!

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

Looks like a proper 500psi & 100psi sensor is in order to properly use the pressure scale.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1195

- Thank you received: 446

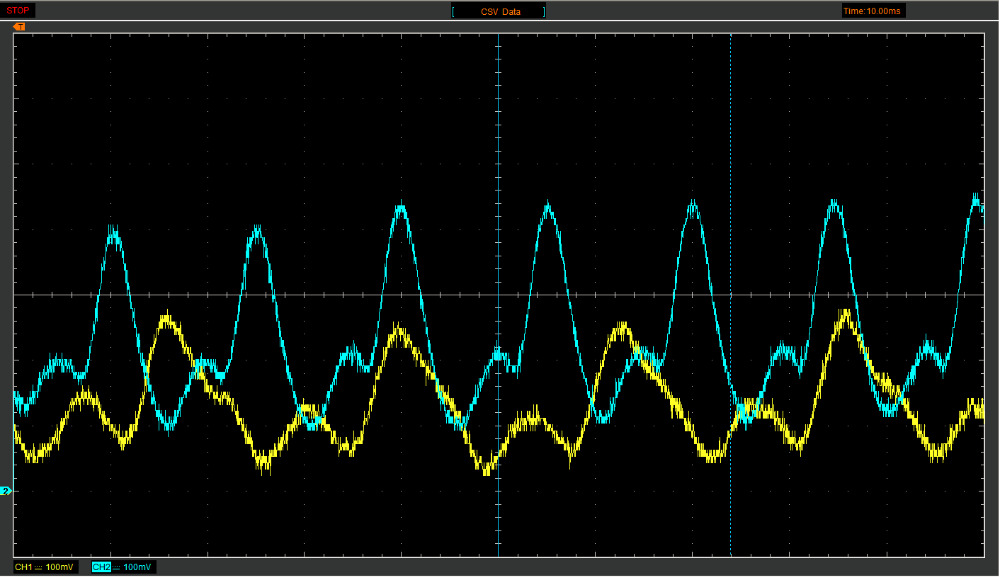

I got frustrated when playing around with these sensors because of the deficient resolution.

Could you upload a screenshot, please?

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

It did seem to respond appropriately while changing the air pressure through my cylinder leak down tester, but obviously the changes taking place were not happening nearly as rapidly as inside a running engine.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

I put it into my Ridgeline but unfortunately got occupied with visitors.

It did look like the sensor output at shorter time samples was choppy and not fluid, almost pixelated, but I was distracted. It could have been me...

After the clean captures from the salvaged refrigerant pressure sensors, I fully expected to see similar, nice, smooth transitions....

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

I do still have access to the Accord by the way. It's out in the yard with no tires, I just haven't had the ambition to go out there pull the head.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1195

- Thank you received: 446

Noah wrote:

I do still have access to the Accord by the way. It's out in the yard with no tires, I just haven't had the ambition to go out there pull the head.

!!Go for it, Forest:) !!

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

Noah wrote: I do still have access to the Accord by the way. It's out in the yard with no tires, I just haven't had the ambition to go out there pull the head.

If it's past the point you can do any more running tests a cylinder leakdown test would probably be enough. That's if you can get compressed air out to it.

Please Log in or Create an account to join the conversation.

- Posts: 4417

- Thank you received: 959

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.